– 27 –

7. IDENTIFICATION AND HANDLING OF FAILURES IN GENERAL

1) Check the area surrounding the high-pressure head of the laser equipment for dirt and moisture.

2) Check whether the high-pressure head is positioned too close to the metallic part of the equipment.

3) Check inside the high-pressure connecting device for breaking of wire or breakage.

4) In the case dew condensation (sweating) of condensed water is formed on the tube walls and wa-

ter-cooled sleeves due to excessively low temperature of the water:

Recommended measure : ① Wind insulating material on the high-pressure head of the laser equip-

ment to separate it from the metallic part.

② Increase the cooling water temperature to 15 - 25 (°C).

7-1. High-tension ignition and electric discharge

1) Water in the laser equipment freezes due to excessively low temperature

2) Water fails to pass inside the laser equipment

3) Water pressure is excessively low

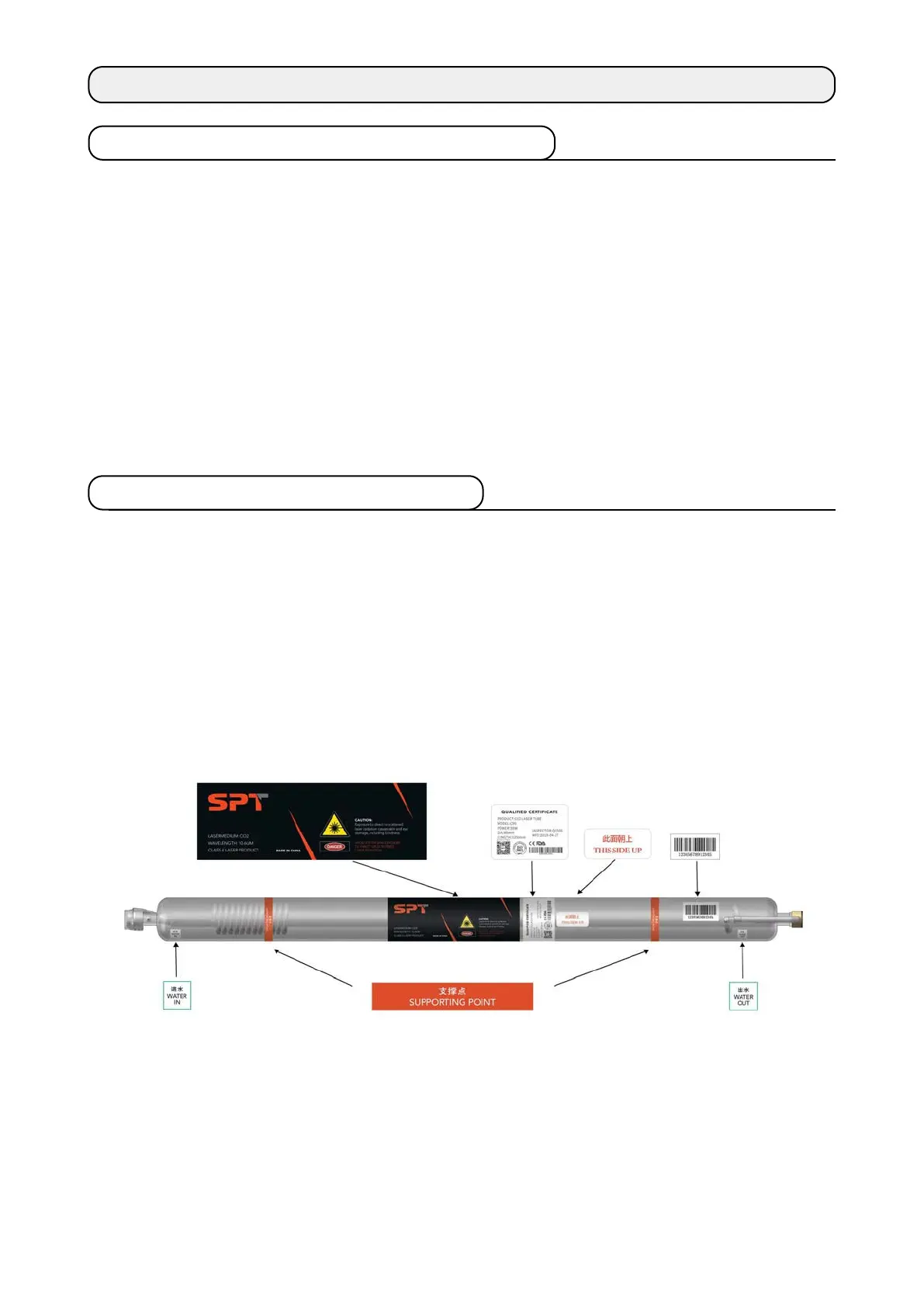

4) Water flows according to the principle of flow of water for the laser equipment such as "water is put

from a lower position and discharged from a higher position". However, the water cooling tube of the

laser equipment is locally heated due to shortage of water.

Recommended measure : ① Use the cooling system.

② See the figure for how to install the cooling system.

7-2. Breakage / rupture of the laser tube

Loading...

Loading...