6

6190755 (Rev A) 86/87R Compressor System User Guide

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Preventive maintenance

Weekly

Drain condensate from air receiver. If

equipped with autodrain, this will take

place automatically, however, drain

bottle has to be emptied.

If compressor is fitted with outlet filter,

check and empty for water by pressing

the black button at the bottom. If fitted

with autodrain, this will take place

automatically.

Check motor, air tubes, hoses and

equipment for leaks, and check the

pumping time.

Clean unit or wipe with a soft, damp

cloth. If necessary, use paraffin on rag

to remove sticky adhesions. Dust and

dirt prevent cooling.

Check intake filter. Clean or replace if

necessary. Minimum every 2000 hours

Replace silencer (intake filter), if

necessary

Check the O-ring in the non-return

valve and replace, if necessary.

Note! Empty receiver of air before

dismounting.

Check filter regulator, clean or replace

as neccessary

Test the safety valve by gently pulling

the ring with pressure in the receiver.

4. Loud noise from system:

a) Dirt or failure in non-return valve. Clean or replace.

5. System gets very hot:

a) Leaks. See above

b) Too high ambient temperature. Ensure adequate ventilation if the

vacuum pump is installed in a cabinet.

c) Overloaded. Ensure system is correct model for work load.

6. System starts when no air is being tapped:

a) Leaks. Step 3 - b

7. System does not switch on against pressure or does not switch

off at max. pressure:

a) Defective pressure switch. Replace.

Non-return valve Maintenance (NRV)

· Once a year.

· Switch off system on the main switch and pull out the plug.

· Pull the ring at the end of the safety valve (see back of manual).

Warning:

Loud noise!

· Let pressure fall to 0 bar. The pressure is to be read on the pressure

gauge for receiver pressure (see back of manual).

· If the system is mounted with a TÜV-approved safety valve, the receiver is

emptied by loosening the screw at the end of the safety valve

· Dismount non-return valve from receiver

· Disassemble non-return valve and remove O-ring from piston

· Clean non-return valve.

· Mount new O-rings and re-assemble non-return valve (Two O-rings in non-

return valve)

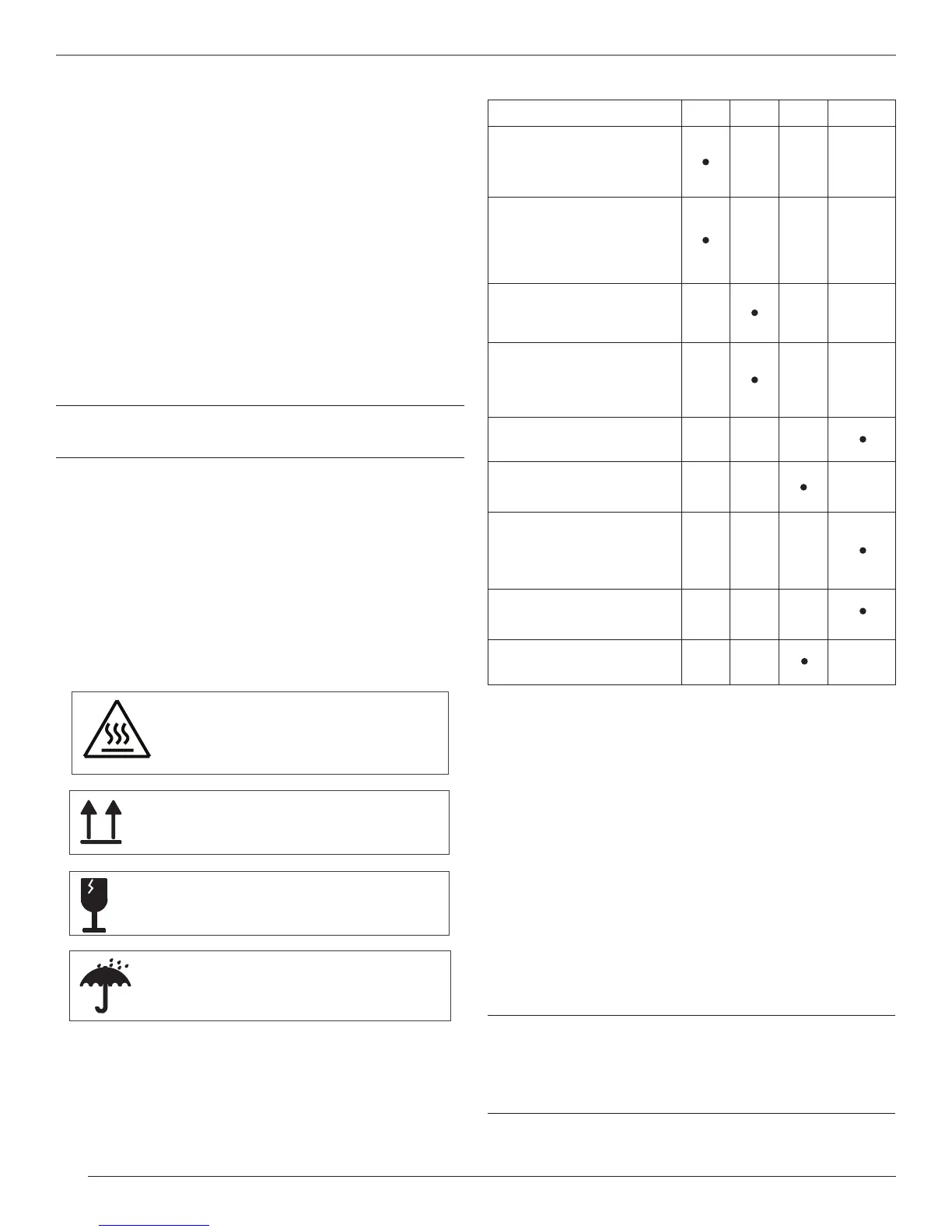

Monthly Annually 2000 Hours

Filters and non-return valves should be serviced every 2000 hours. The JUN-AIR basic service kit (identified in the accessories

portion of this manual) can be purchased to accommodate.

The comprehensive service kit includes components to maintain the system’s compressor (cups, valves, o-rings, cylinders) as well as

the systems filter elements, unloader valve, silencer, & NRV.

Comprehensive service kits should be utilized every 8000 hours.

Any solenoid accessories on the system should be serviced every 12000 hours.

Check the Pumping Time

The pumping time indicates the condition of the compressor provided that

there are no leaks in the system where the compressed air may leak. Test the

compressor as follows:

1. Empty the air receiver of compressed air ( the pressure gauge shows 0 Bar)

2. Close the outlet on the air receiver and check that the drain cock is closed.

3. Start the compressor and note how long it takes until it switches off.

Ensure that the pressure in the air receiver is 8bar/120 psi as deviations may

indicate the wrong results (see technical Specifications for pumping time)

Important!

Always test the compressor when cold as the time indicated

refers to the pumping time of a cold compressor. The pumping

time of a warm compressor is much longer and consequently,

the result would be misleading.

WARNING: To Avoid Serious Burns:

Do not touch surface during

operation.

Indicates package should be handled with

these symbols pointing up.

FRAGILE: Handle package with care.

Indicates this package must be kept dry.

Loading...

Loading...