30

Service and Repair Manual

Model 900/950/990

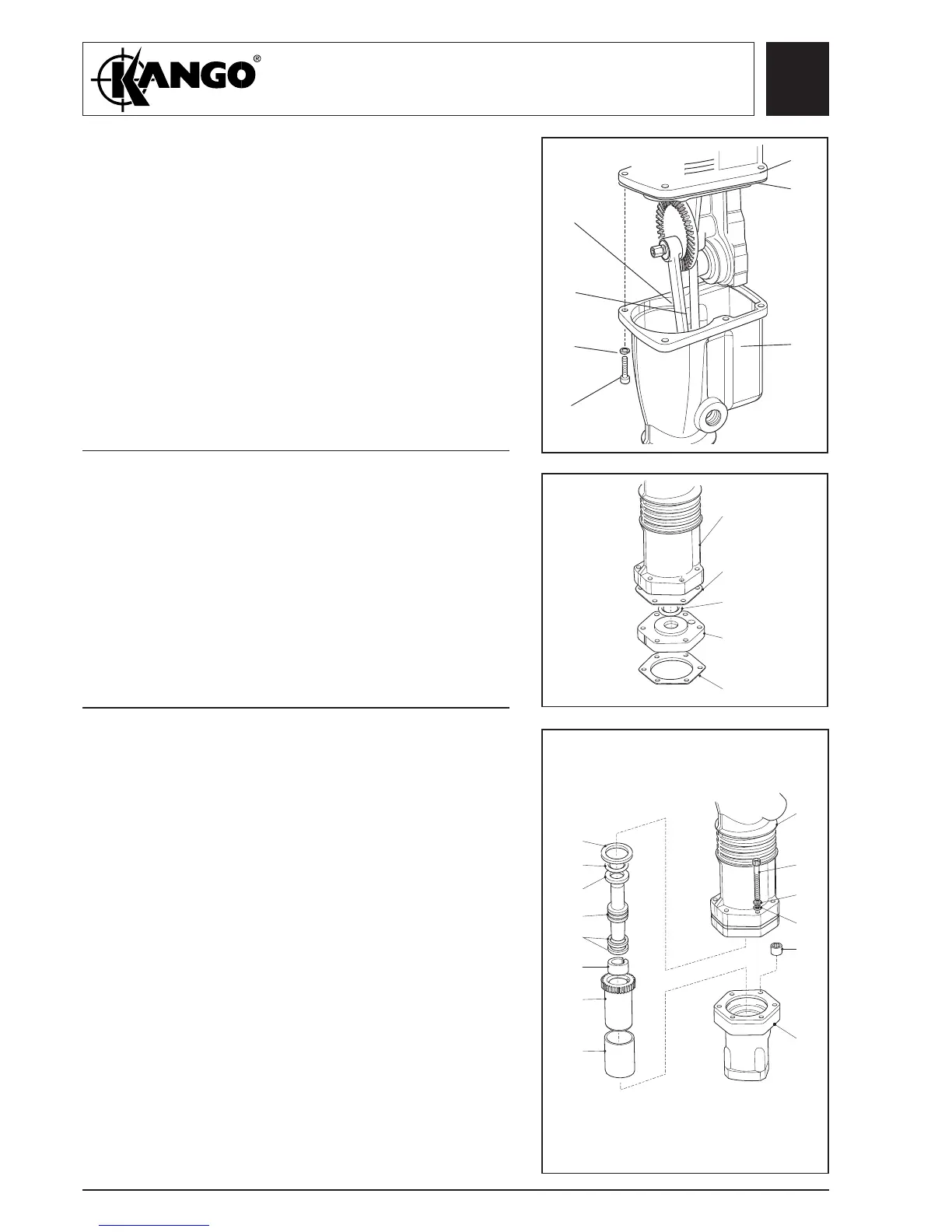

1. Fit the hammer case (346, 228, 428, 528)

vertically in a vice between soft metal jaws.

2. Lightly grease the hammer case gasket (150) and

locate on the hammer case.

3. Fit the assembled motor and gear carrier into the

hammer case. For 950 models ensure the drive

shaft (345) is correctly located.

4. Secure the hammer case using the six screws

(348, 227, 427, 527) and washers (347, 226, 426,

526).

Fitting the

hammer case

(All models,

950 shown)

347

226

426

526

149

150

346

228

428

528

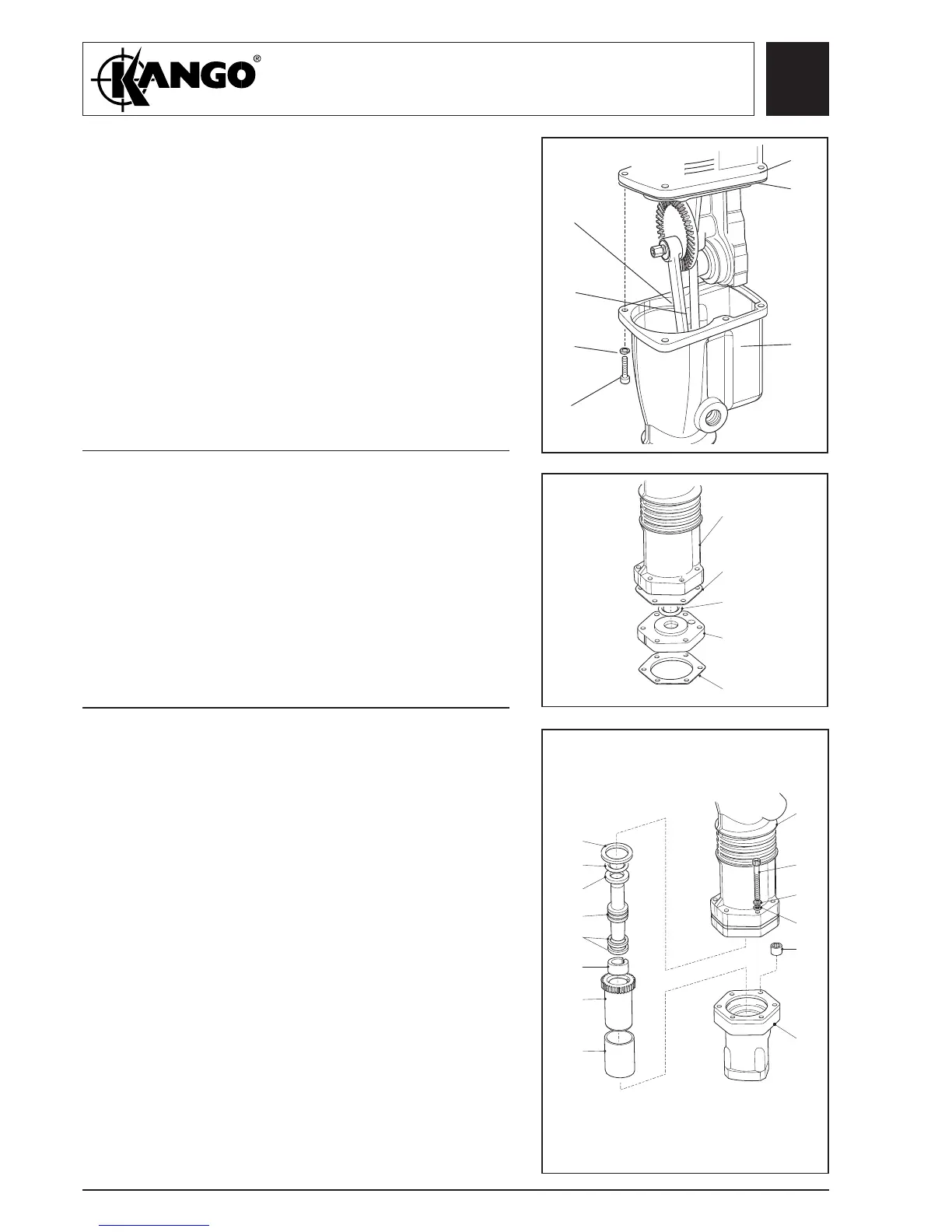

Fitting the

buffer

housing (All

models,

model 950

shown)

1. Press the buffer housing ring (353, 232) into the

groove in the buffer housing (354, 233).

2. Fit the buffer housing gasket (352, 231) to the

hammer casing (346, 228).

3. Fit the buffer housing (354, 208) and buffer

housing gasket (375, 234) to the hammer casing.

4. For 990 only fit spacer (432) and extra gasket

(231, 352, 433) between gasket and buffer

housing.

Assembling

the

transmitter

housing (All

models,

model 950

shown)

1. Place the transmitter housing (359) vertically in a

vice between soft metal jaws. Using service tool,

part no. 917003270, press the drive shaft bearing

(374) into the transmitter housing . Press the

driver bearing (371) into the transmitter housing

(359). (Model 950 only).

2. Insert the junk ring (373, 240), with the flat

surface down, into the driver (372) or anvil

sleeve.

3. Insert the recoil transfer ring (356, 237), rubber

ring (355, 236) into the transmitter housing.

4. Fit the two anvil rings (358, 239) on to the anvil

(357, 238) and insert the anvil into the driver

(372) or anvil sleeve. Insert the anvil and driver

assembly into the transmitter housing (369, 242).

5. Fit the assembled transmitter housing to the

hammer casing and secure with the six screws

(349, 229), spring washers (350, 230).

348

227

427

527

345

(950

ONLY)

305

205

405

505

Fig. 40

Fig. 41

Fig. 42

235

355

236

356

237

357

238

358

239

373

240

371

372

349

229

350

230

351

346

228

374

369

242

439

354

233

375

234

346

228

352

231

353

232

Loading...

Loading...