33

Service and Repair Manual

Model 900/950/990

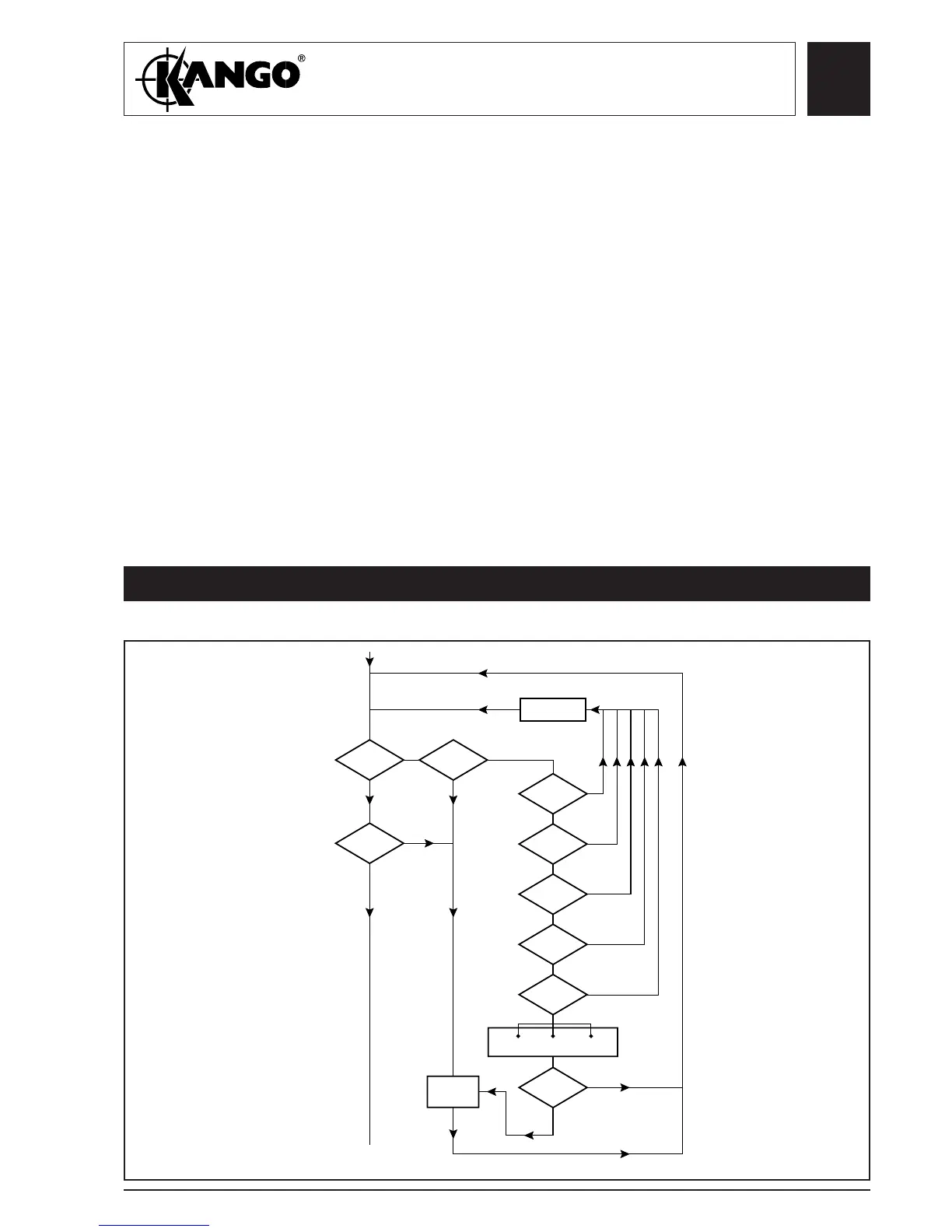

With the aid of the Fault Finding chart (below) the source of any malfunction may be quickly identified and repaired.

REMEDY FAULT

AND RETEST

MOTOR

REVOLVES?

MACHINE

HAMMERS?

MACHINE

IDLES?

SUPPLY

OK?

PLUG FUSE

OK?

BRUSHES

OK?

CORD

OK?

SWITCH

OK?

ARMATURE FIELD INTERNAL

WIRING

SERVICE

MECHANISM

MODULE

WAS MOTOR

BURNT OUT?

MACHINE

OK

YES

NO NO

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

ON COMPLETION OF ASSEMBLY THE UNIT SHOULD BE FLASH TESTED AT

4000 VOLTS. THE UNIT SHOULD BE RUN PREFERABLY AT HALF STATED

VOLTAGE FOR 10 MINUTES TO ENSURE CORRECT BEDDING OF BRUSHES.

AFTER 10 MINUTES THE UNIT SHOULD BE RUN AT FULL STATED VOLTAGE.

POWER READINGS SHOULD BE CHECKED AGAINST THE PERFORMANCE

DATA.

With the breaker completely assembled and with the switch "ON" apply not more than 2000 volts

initially and then raise quickly to 4000 volts between the main casting and one of the pins of the

plug on the power supply cord.

LETHAL VOLTAGES PRESENT - DO NOT TOUCH PINS

The full voltage of 4000 volts should be maintained without breakdown or flashover for a few

seconds.

If, however, the armature has already been tested then it is better to remove the carbon brushes

before carrying out the test. This avoids over-stressing the armature insulation system for a second

time. In this case the test voltage must be applied between the main casting and each live pin of the

plug in succession.

FAILURE TO SWITCH THE MACHINE ON MAY CONCEAL A FAULT WHICH

WILL RESULT IN AN ELECTRIC SHOCK TO THE USER. ENSURE THAT THE

SWITCH IS ON BEFORE TESTING.

WARNING

WARNING

WARNING

FAULT FINDING

Loading...

Loading...