13

Service and Repair Manual

Model 900/950/990

DISMANTLING

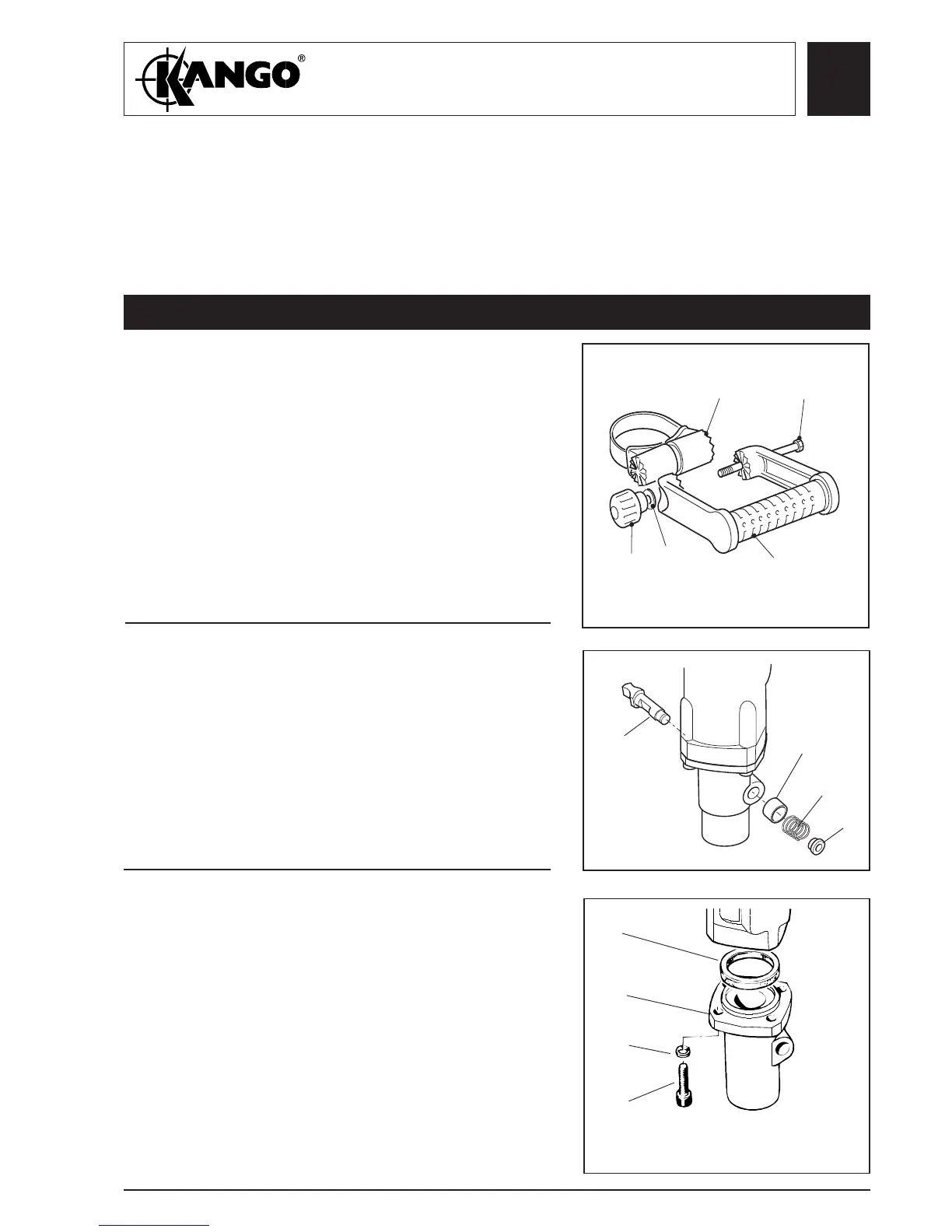

360

249

362

251

359

248

363

252

Important! Before carrying out any repairs the hammer should be checked for electrical safety and for mechanical

performance. For electrical safety the hammer should be placed on a non-conductive surface which is

either of a wooden construction (with the mains supply disconnected) which contains no metal parts or a

bench which is insulated by a rubber mat. The hammer should then be checked by high voltage flash

testing. On completion of dismantling procedure all electrical components should then be checked for

electrical safety. The hammer should ONLY be checked for hammer performance if the unit passes the

electrical safety test.

Note: In the disassembly instructions numbers

starting 200 are Model 900, numbers starting

with 300 are Model 950, numbers starting

with 400 are Model 990, numbers starting

with 500 are Model 900M in both text and

illustrations.

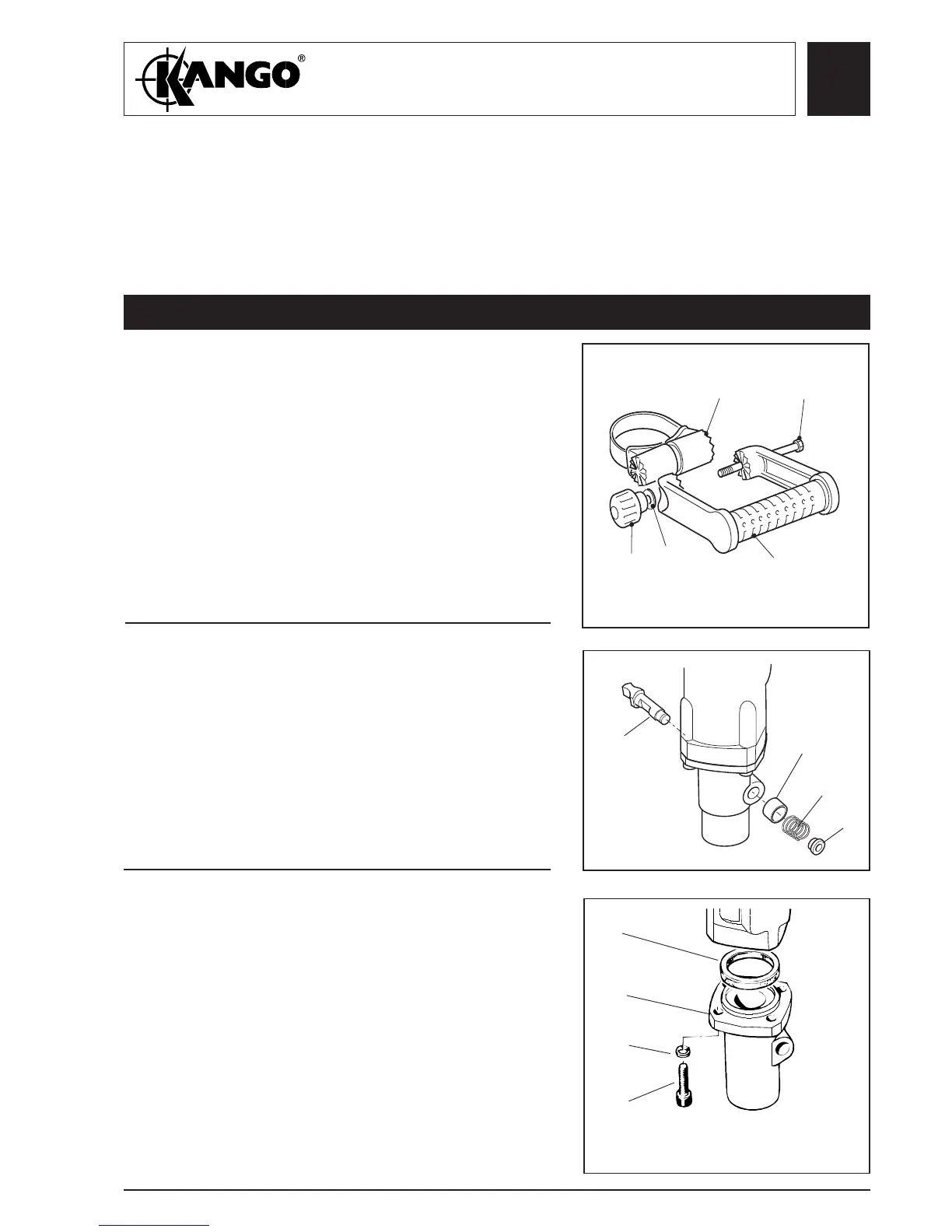

1. Remove knob (460), washer (459) and bolt (457).

2. Remove handle (458) and strap casing (456).

Removing

the forward

handle

(All models,

950 shown)

1. Using a suitable drift on the latch bar remove the

latch retainer (360, 245,), latch spring (363, 252),

latch spring cover (362, 251) and latch bar (359,

248).

Removing the

latch bar

mechanism.

(All models -

950S shown

except 900M)

Fig. 2

Fig. 1

Removing the

nosepiece.

(All models -

950S shown

except 900M)

1. Remove the four screws (365, 246, 443) and four

spring washers (366, 245, 442) from nosepiece

(367, 247, 444). Note that the screws are secured

by Loctite.

2. Remove the nosepiece (367, 247, 444) and driver

sealing felt (368) or compression ring (244, 441)

- (Model 900 & 990 only).

368

244

441

367

247

444

366

245

442

365

246

443

Fig. 3

460

459

458

456

457

Loading...

Loading...