5.1 Maintenance 5.1

CLEANING AND LUBRICATION

It is good practice to keep a dust sheet over the cutter if it is not to be used for extend-

ed periods. In any event regularly clean it with a dry cloth or to remove any stubborn

stains use a cloth dampened with a little water/detergent.

Should the cutting head slideway require lubrication use a silicon spray or silicon

impregnated sponge.

CUTTING HEAD BEARINGS

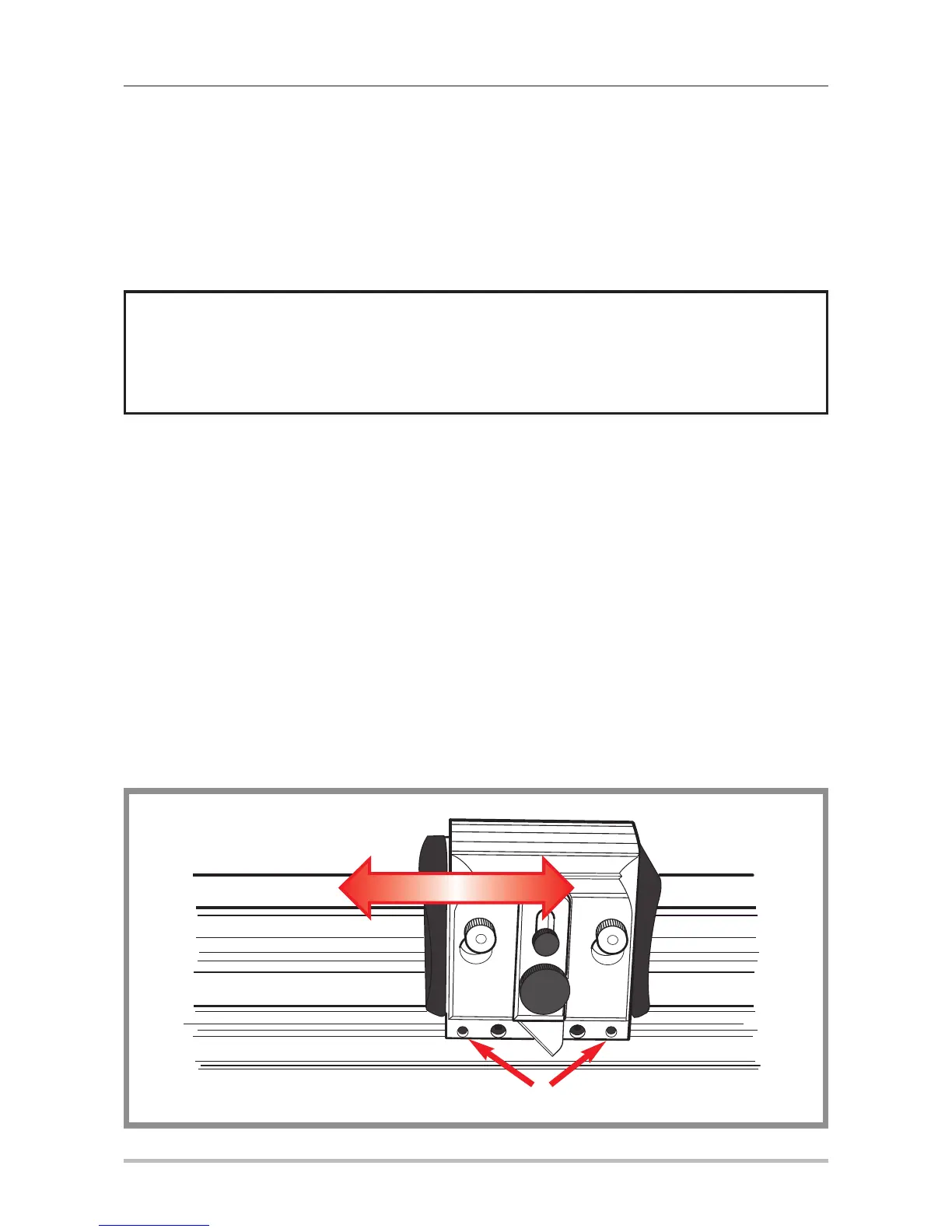

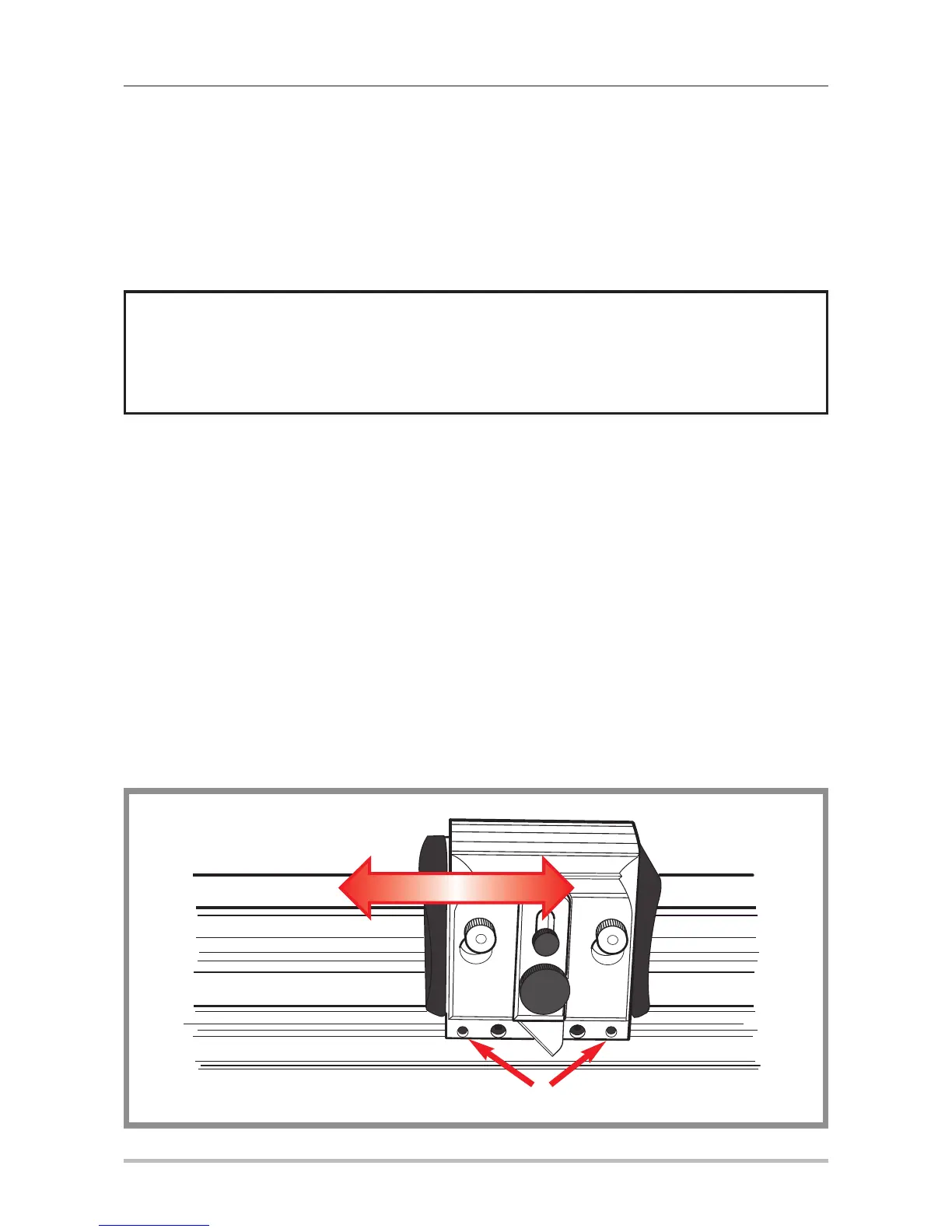

The bearings that control the sliding motion of the cutting head are manufactured from a

high grade polymer and under normal use will last for an extremely long time. As they

settle into position you may find a slight amount of side play, this can be removed by

tightening the two adjustment screws:

Place the long end of the 2mm Allen key provided into any of the two screws

J

and

very gradually tighten it with one hand whilst moving the cutting head up and down the

cutter bar with the other. Once you feel the sliding motion start to tighten undo the

screw the smallest amount so the cutting head just slides easily.

Repeat this on the other screw, further finer adjustment on each screw may be needed

to achieve an easy sliding movement with zero side play.

■ Please note! DO NOT Use mineral oil or solvents to lubricate or clean the

cutter, because the plastic components and bearings will be damaged.

J

KEENCUT Limited accepts no liability if the product is not assembled and used in the correct way.

Loading...

Loading...