TECHNICAL SERVICE MANUAL FOR MASTERTIG ACDC

TROUBLESHOOTING CHART

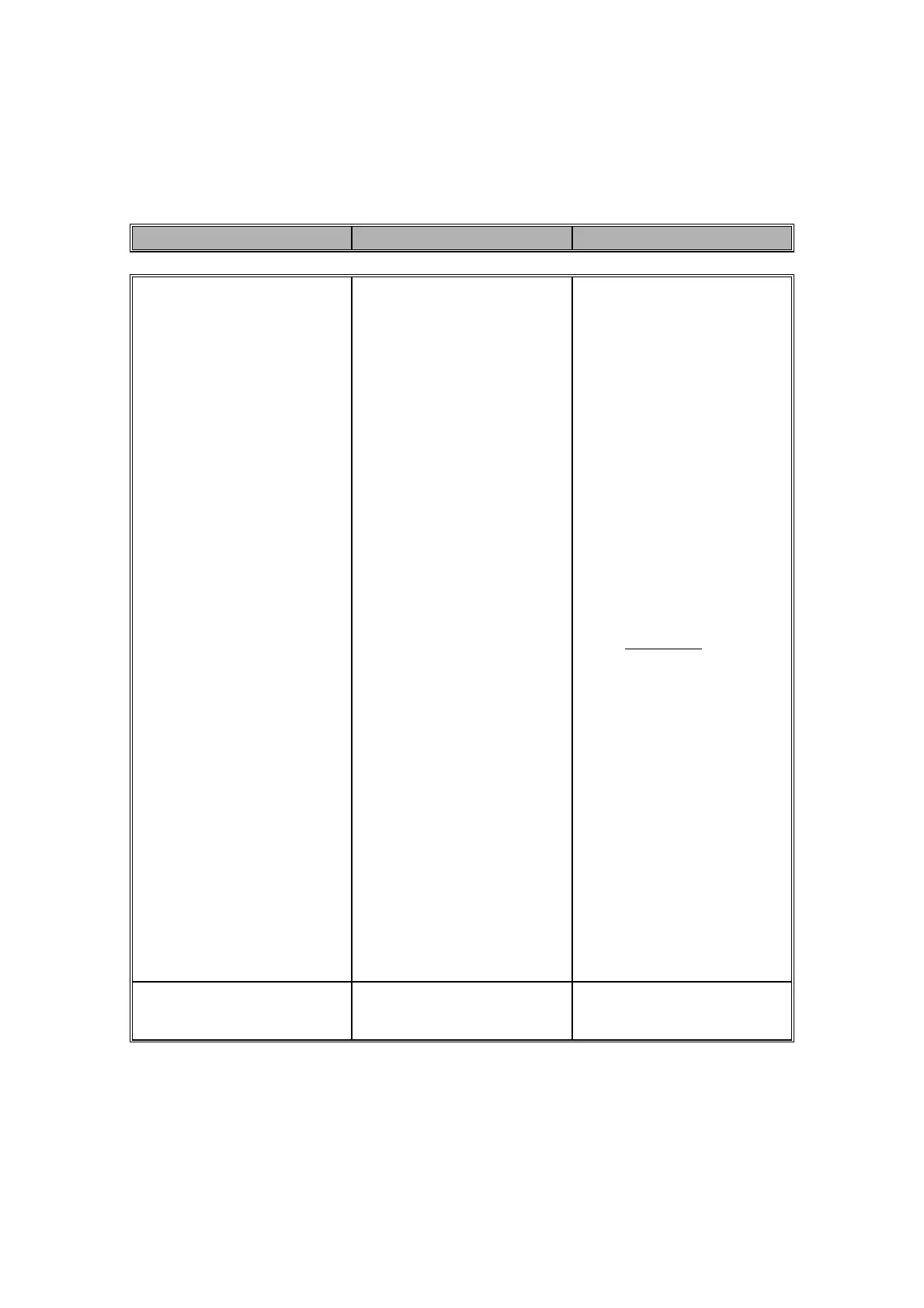

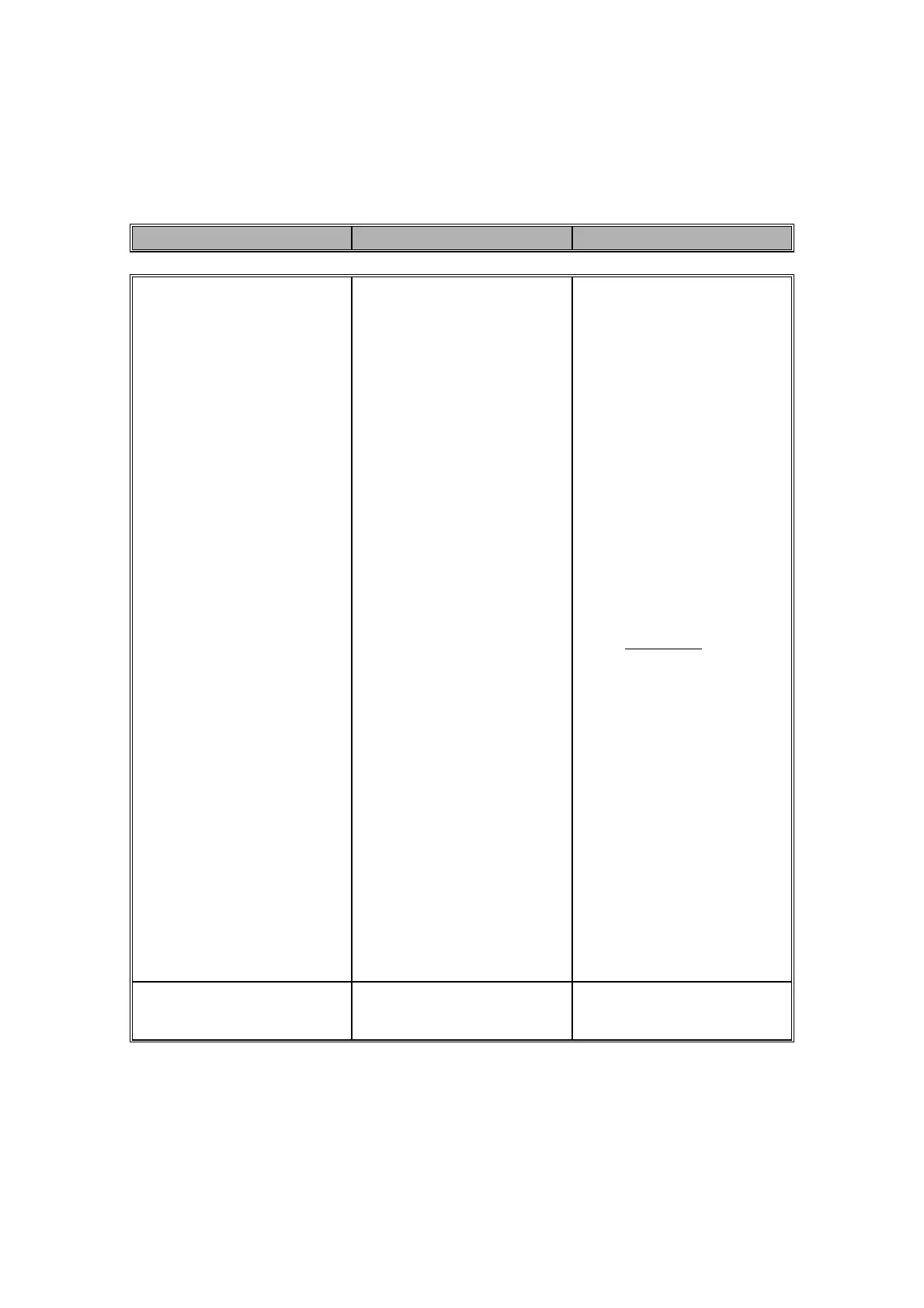

PROBLEM CAUSE REMEDY

The cooling unit is not operational

or H001 light is on.

The water doesn’t circulate by switch

SW302.

Water doesn’t return back to the

tank.

Blown fuse F002 2A.

Broken or faulty auxiliary-

transformer T005.

Broken pressure switch S002.

Pressure switch set value is

unsuitable for the

TIG torch which

is in use (other than original Kemppi

torch).

Air bubbles in the system.

Leakages in the cooling system.

Pump motor 5µ starting capacitor

C004 is faulty.

Broken or faulty PCB A005 .

Check and change the fuse if

needed.

Check first the supply voltage of

transformer from Z004, connector

1=230V, 2=400, and 3=460V. Then

check the secondary voltage of

transformer, check it from terminal

block XW301 between 4 an 5 the

voltage is c. 230 VAC.

Check the voltage over the pressure

switch or from PCB A005 X2/1 and

X2/8; enough pressure 0V and lack

of pressure c. 5V.

Adjust the pressure set value from

the adjustment screw, of pressure

switch according following

instructions:

I

START PRESSING TEST SWITCH

SW302 AND ADJUST THE ADJUSTMENT

SCREW

(SEE PICTURE 3.) FOR

PRESSURE, IN SUCH WAY THAT THE

SIGNAL LAMP

H001 IS ONLY JUST

SWITCHED OFF

.

II

RELEASE SWITCH SW302 AND WAIT

FOR APPR

. 10 S AND CHECK THAT

SIGNAL LAMP

H001 IS NOT FLASHING.

III

STILL CHECK BY WELDING FOR

APPROX

. 20 S THAT THERE ARE NO

MORE DISTURBANCES

.

Blow compressed air into tank,

closing the filling hole by hands is

enough.

Check/repair the connection of

cooling system connector by

connector. Repair the system if

needed.

Check and change the capacitor if

needed.

Change/repair PCB A005.

The solenoid valve Y001 is not

operating // stuck open

Faulty solenoid valve Y001 or

broken PCB A002.

Check the 24 VDC from A002

connector X9 between pins 1and 2.

If it is ok, change the solenoid valve.

Loading...

Loading...