TECHNICAL SERVICE MANUAL FOR MASTERTIG ACDC

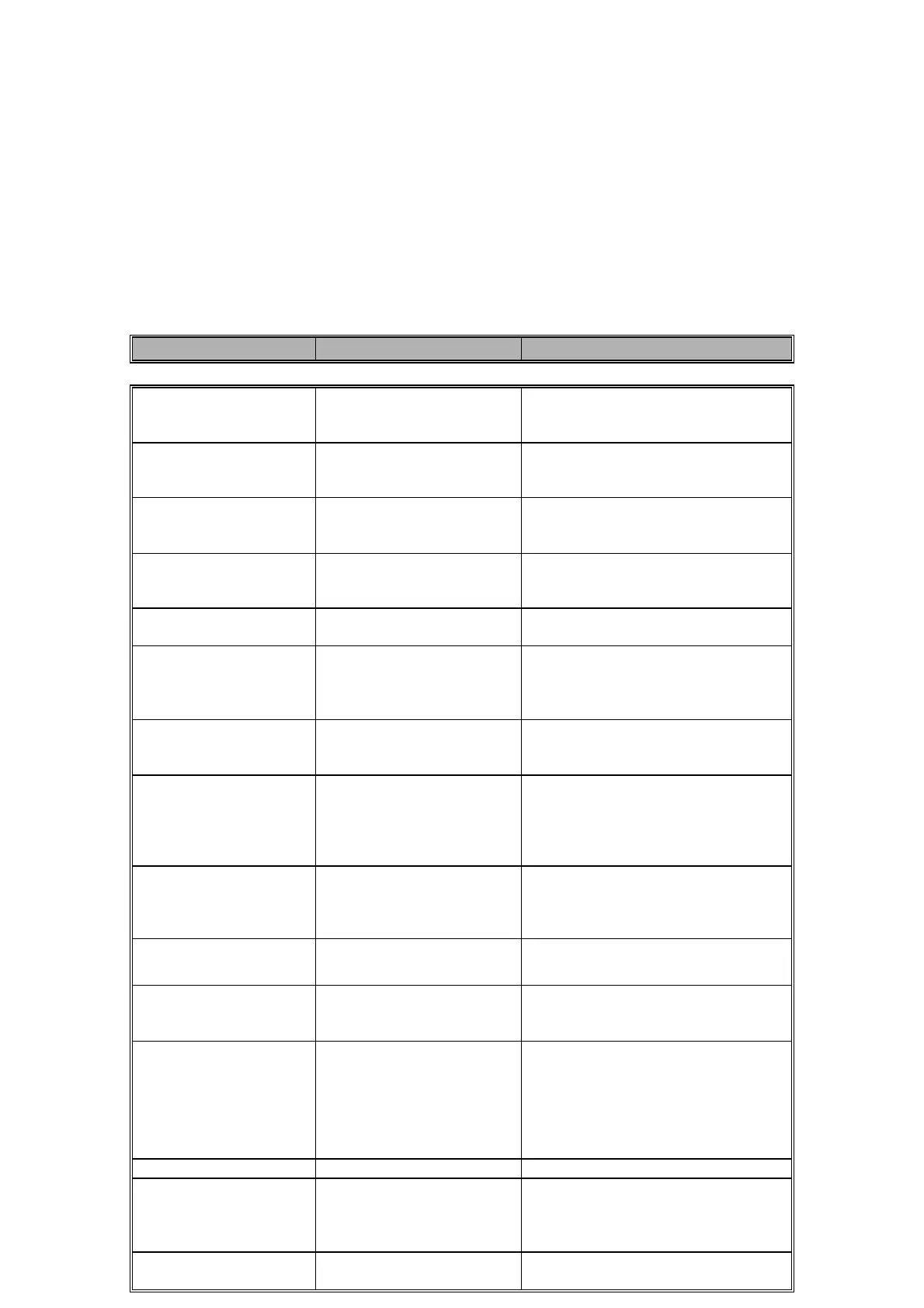

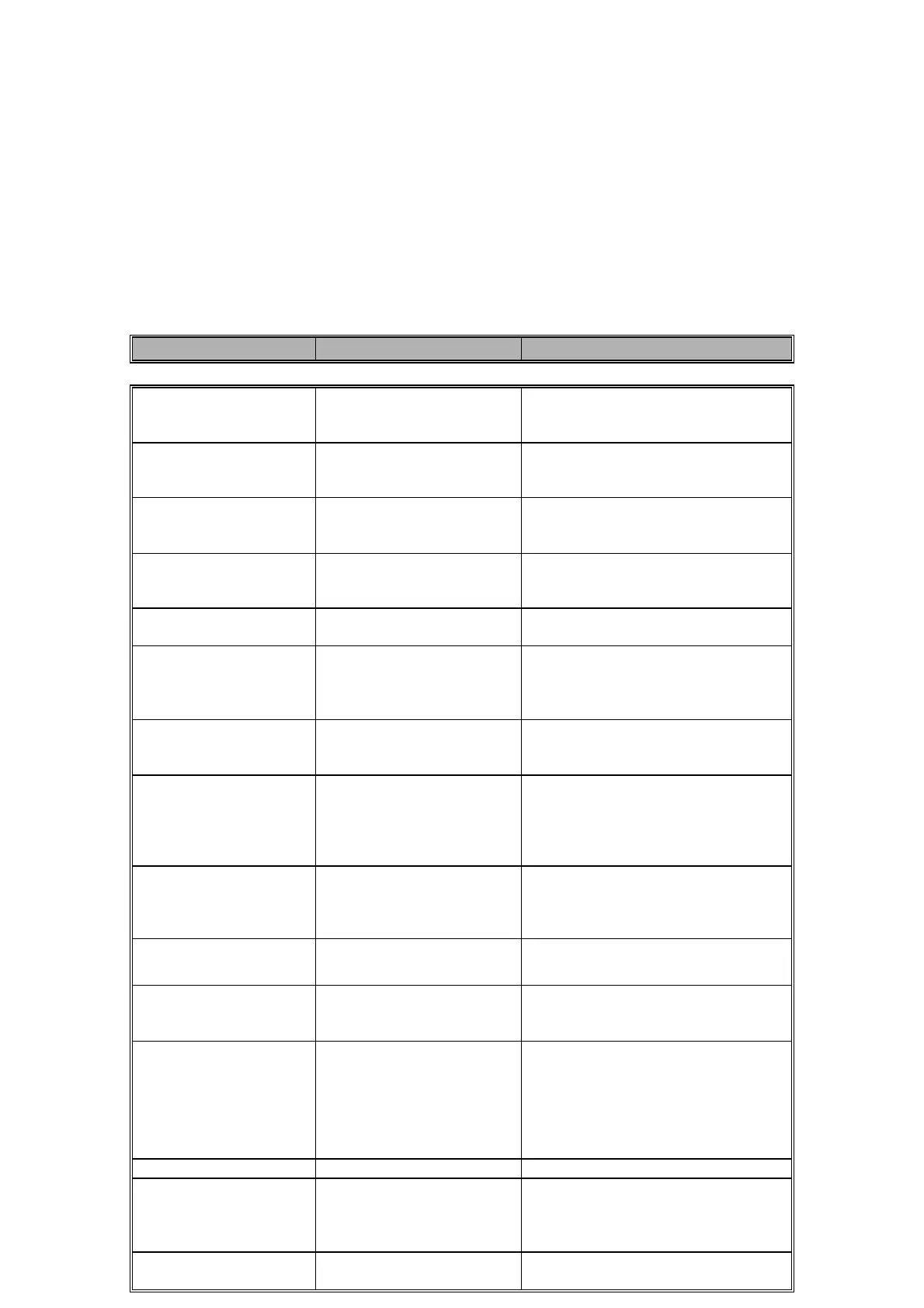

TABLE OF JUMPERS, EXTRA FUNCTIONS.

In addition to the standard Master-tig functions there are some extra features

which may be called up by using the so called ‘electronic jumpers’. These

jumpers may be set to tailor the machine to the customer’s needs and include

the following;

JUMPER NUMBER FUNCTION ON FUNCTION OFF

J01

UP SLOPE

UP SLOPE TIME DEPENDS ON

SET VALUE OF CURRENT

UP SLOPE TIME IS INDEPENDENT OF SET

VALUE OF CURRENT

J02

DOWN SLOPE

DOWN SLOPE TIME DEPENDS

ON SET VALUE OF CURRENT

DOWN SLOPE TIME IS INDEPENDENT OF

SET VALUE OF CURRENT

J03

TIG ANTIFREEZE

TIG ANTIFREEZE IS ON TIG ANTIFREEZE IS OFF

J04

AC

BALANCE

MANUAL

AC BALANCE

CONTROL IS IN USE

SMART BALANCE FUNCTION IS IN USE,

SCALE OF PANEL IS IN USE

J05

TACK WELDING

TACK WELDING IS AUTOMATIC DOWN SLOPE FUNCTIONS IMMEDIATELY

J06

DOWN SLOPE CUT OFF

LEVEL

DOWN SLOPE CUT OFF LEVEL

IS MINIMUM CURRENT

DOWN SLOPE CUT OFF LEVEL IS

20 %

OF SET VALUE

J07

OPEN CIRCUIT VOLTAGE

OPEN CIRCUIT VOLTAGE

IS

70 V

OPEN CIRCUIT VOLTAGE IS C. 39.5 V

J08

“

CHINA LOGIC”

TIG WELDING IN 4T

POSSIBILITY TO PRESET

STARTING CURRENT

,

WELDING CURRENT AND

END CURRENT

NORMAL

4T FUNCTION

J09

Inverter Frequency

I

NVERTER FREQUENCY IS 18

KHZ IN THE WHOLE CURRENT

RANGE

INVERTER FREQUENCY IS 18 KHZ/ 36

KHZ IN MMA!

J10

2T Hot/ soft start

H

OT/ SOFT START IS IN USE

WITH

TIG 2T LOGIC

J11

2T Hot/ soft start time

setting

H

OT/ SOFT START TIME IN 2T

LOGIC. ADJUSTMENT RANGE

IS

0,0-9,9 SECONDS

J12

2T Downslope

I

N 2T THE DOWNSLOPE

DOESN

´T END WITH A SHORT

OR A LONG PULL

, SO THE

WELDING CURRENT CAN BE

TAKEN UP AND DOWN WITH A

SHORT PULL ON THE TRIGGER

IN 2T THE WELDING IS ENDED DURING

DOWNSLOPE WITH A SHORT PULL ON

THE TRIGGGER

J13-15

N

OT IN USE

JO16

POSITIVE START CYCLE OF

AC-TIG

ADJUSTMENT FOR LENGTH OF

POSITIVE START CYCLE

,

FACTOR 0.0 2.0

FACTORY SETTING IS 1

JO17

MMA

IGNITION PULSE

ADJUSTMENT OF

MMA

IGNITION PULSE (0,0-2,0)

FACTORY SETTING IS 1

Loading...

Loading...