(3) Connect the VTVM to terminal TP2 and adjust the

core of L10 180' counterclockwise from the point

where oscillation begins.

RF voltage of TP2

=

0.7

-

1 V

(4) Adjust the core of L11 so that the RF voltage across

terminal TPI is maximum.

RF voltage at TPI

=

0.1 5

-

0.3V

(5)

Adjust the core of L11 so that the RF voltage at

terminal PI is maximum, and then readjust the core

of L4. RF voltageat PI

=

1 -2V

(6) Adjust TC1 so that the DC voltage terminal CV is

5 v.

Note:

The

PLL

will work properly after steps

(1)

-

(6)

and the

unlock indicator on the panel will go off.

(7) Adjust the core of

L15 so that the RF voltage at

terminal LR is maximum.

RF voltage at LR

=

0.3

-

1 V

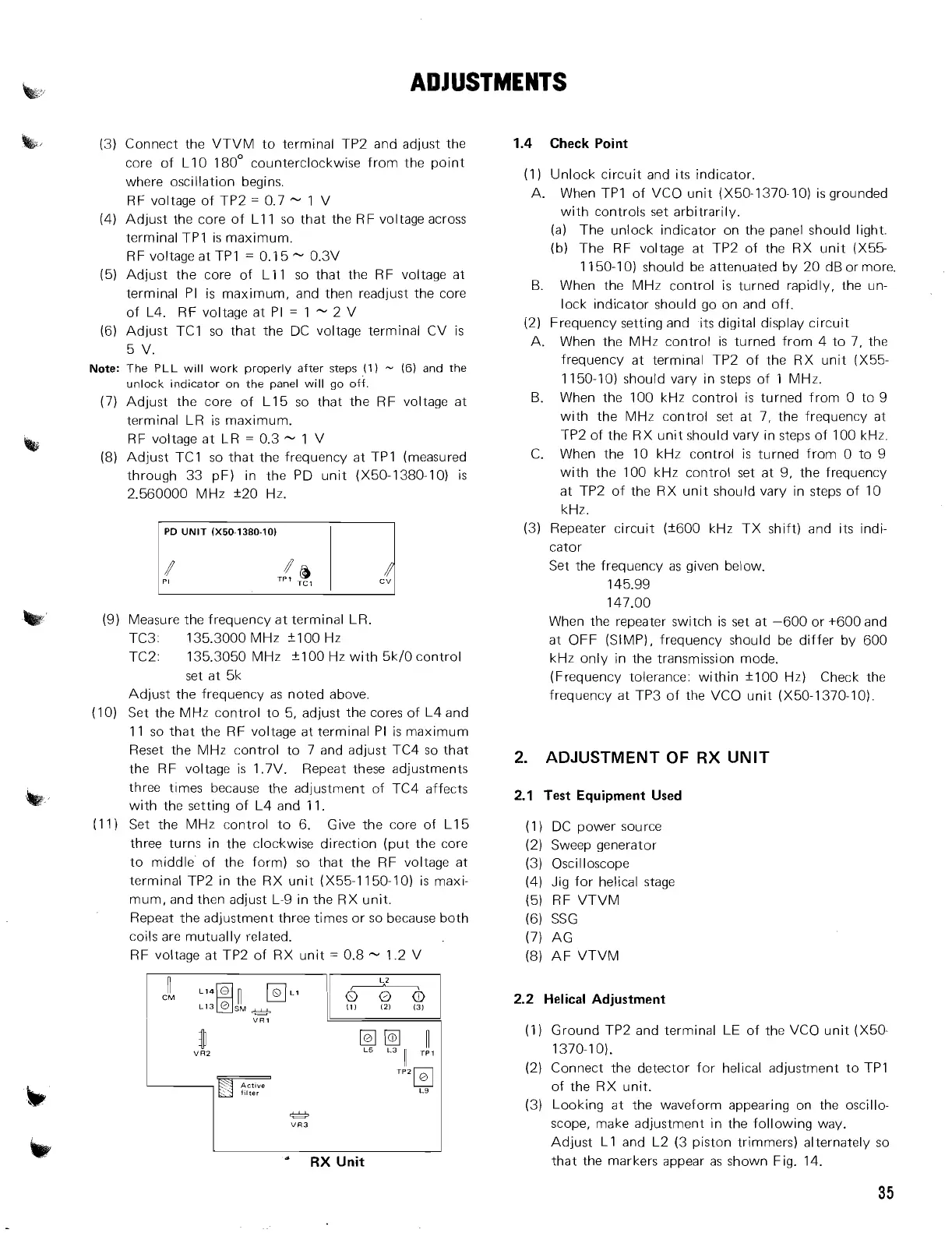

(8) Adjust TC1 so that the frequency at TPI (measured

through 33 pF) in the PD unit (X50-1380-10) is

2.560000 MHz f20 Hz.

(9) Measure the frequency at terminal LR.

TC3: 135.3000 MHz

"00 Hz

TC2: 135.3050 MHz +I00 Hz with 5k/0 control

set at 5k

Adjust the frequency as noted above.

(10) Set the MHz control to 5, adjust the cores of L4 and

11 so that the RF voltage at terminal PI is maximum

Reset the

NlHz control to 7 and adjust TC4 so that

the RF voltage is 1.7V. Repeat these adjustments

three times because the adjustment of TC4 affects

with the setting of L4 and 11.

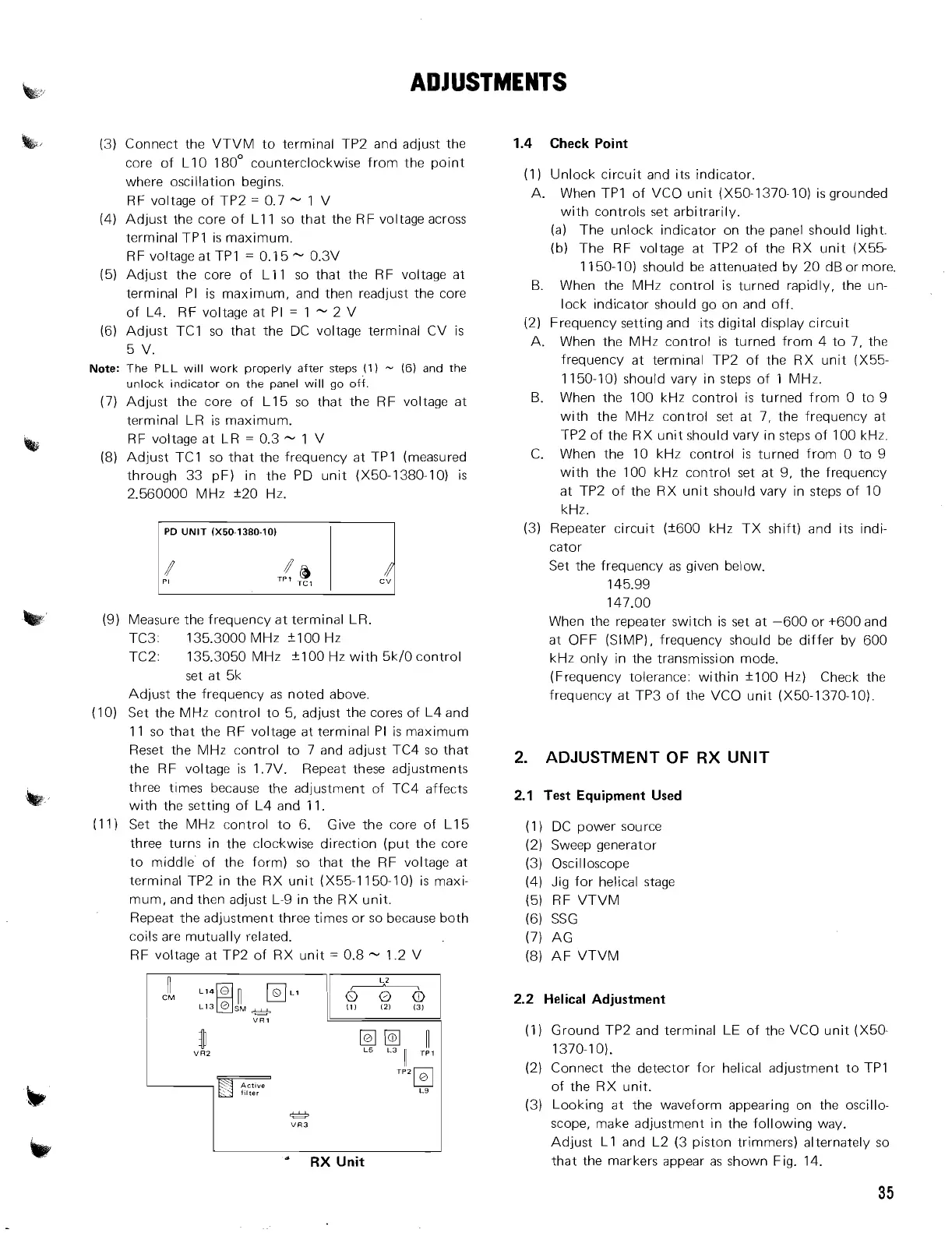

(1 1) Set the MHz control to 6. Give the core of L15

three turns in the clockwise direction (put the core

to middle' of the form) so that the RF voltage at

terminal TP2 in the RX unit (X55-I 150-10) is maxi-

mum, and then adjust L-9 in the RX unit.

Repeat the adjustment three times or so because both

coils are mutually related.

RF voltage at

TP2 of RX unit

=

0.8

-

1.2 V

I

VRl

111

L5

L3

1

TPl

I

"

RX

Unit

1.4 Check

Point

(1) Unlock circuit and its indicator.

A. When TPI of VCO unit (X50-1370-10) is grounded

with controls set arbitrarily.

(a) The unlock indicator on the panel should light.

(b) The RF voltage at TP2 of the RX unit (X55-

1150-10) should be attenuated by 20 dB or more.

B. When the MHz control is turned rapidly, the un-

lock indicator should go on and off.

(2) Frequency setting and its digital display circuit

A.

When the MHz control is turned from 4 to 7, the

frequency at terminal TP2 of the RX unit (X55-

1150-10) should vary in steps of 1 MHz.

B. When the 100 kHz control is turned from 0 to 9

with the MHz control set at 7, the frequency at

TP2 of the RX unit should vary in steps of 100 kHz.

C. When the 10 kHz control is turned from 0 to 9

with the 100 kHz control set at 9, the frequency

at TP2 of the RX unit should vary in steps of 10

kHz.

(3) Repeater circuit (f600 kHz TX shift) and its indi-

cator

Set the frequency as given below.

145.99

147.00

When the repeater switch is set at -600 or

+600 and

at OFF (SIMP), frequency should be differ by 600

kHz only in the transmission mode.

(Frequency tolerance: within +-I00 Hz) Check the

frequency at TP3 of the VCO unit (X50-I 370-10).

2.

ADJUSTMENT

OF

RX

UNIT

2.1 Test Equipment Used

(1

)

DC power source

(2) Sweep generator

(3) Oscilloscope

(4) Jig for helical stage

(5) RF VTVM

(6) SSG

(7) AG

(8) AF VTVM

2.2 Helical Adjustment

(1) Ground

TP2 and terminal LE of the VCO unit (X50-

1370-1 0).

(2) Connect the detector for helical adjustment to TPI

of the RX unit.

(3) Looking at the waveform appearing on the oscillo-

scope, make adjustment in the following way.

Adjust

L1 and L2 (3 piston trimmers) alternately so

that the markers appear as shown Fig. 14.

3

5

Loading...

Loading...