Do you have a question about the Kinetico CP 213s OD and is the answer not in the manual?

Details specifications for Kinetico CP 208 model softeners with 8x40" tanks, including flow rates and capacities.

Details specifications for Kinetico CP 210 model softeners with 10x54" tanks, including flow rates and capacities.

Details specifications for Kinetico CP 213 model softeners with 13x54" tanks, including flow rates and capacities.

Details specifications for Kinetico CP 216 model softeners with 16x65" tanks, including flow rates and capacities.

Provides charts to determine optimal system sizing based on water hardness and continuous flow rate for various models.

Describes the Level One assembly components and their roles in treating water and initiating regeneration.

Details the function of the water meter disc in adjusting regeneration frequency and initiating regeneration cycles.

Explains how the Control Disc manages internal valve positions and sequences service and regeneration based on system type.

Outlines necessary changes to Venturi Throat and Brine Flow Control for specific CP units in central brining operations.

Emphasizes confirming system configuration, components, and facility operating data before beginning installation.

Details the step-by-step installation process for CP 208 through CP 216 models, including media loading and connections.

A systematic approach to diagnosing issues, starting with gathering information and testing the water.

Guides users on how to resolve common complaints and problems encountered with water treatment systems.

Troubleshooting steps for a non-turning water meter disc, including reasons like pawl issues or damaged teeth.

Diagnoses issues preventing automatic regeneration, such as a stationary meter disc or control disc problems.

Addresses problems with brine vacuum, including plugged venturi, flow controls, or brine elbow screens.

Explains causes of short salting, such as an unlevel brine drum affecting water level and salt dissolution.

Troubleshooting steps for units regenerating too often, often caused by an incorrectly labeled meter disc.

Troubleshoots salty water caused by kinked or clogged drain lines, ensuring smooth flow.

Addresses salty water due to low water pressure, recommending pressure testing and potential increases.

Troubleshoots reduced pressure by checking for clogged prefilters and recommending replacement.

Diagnoses leaks to drain caused by improperly seated balance piston O-rings, suggesting reseating or replacement.

Troubleshoots leaks from assembly levels by checking screw tightness, seals, and screw hole integrity.

Diagnoses unit sticking in regeneration/backwash due to plugged flow paths, weak pawls, or damaged control discs.

Addresses units stuck in service cycle, typically caused by a broken or missing regeneration start pawl or worn control disc.

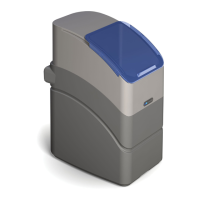

| Brand | Kinetico |

|---|---|

| Model | CP 213s OD |

| Category | Water Dispenser |

| Language | English |