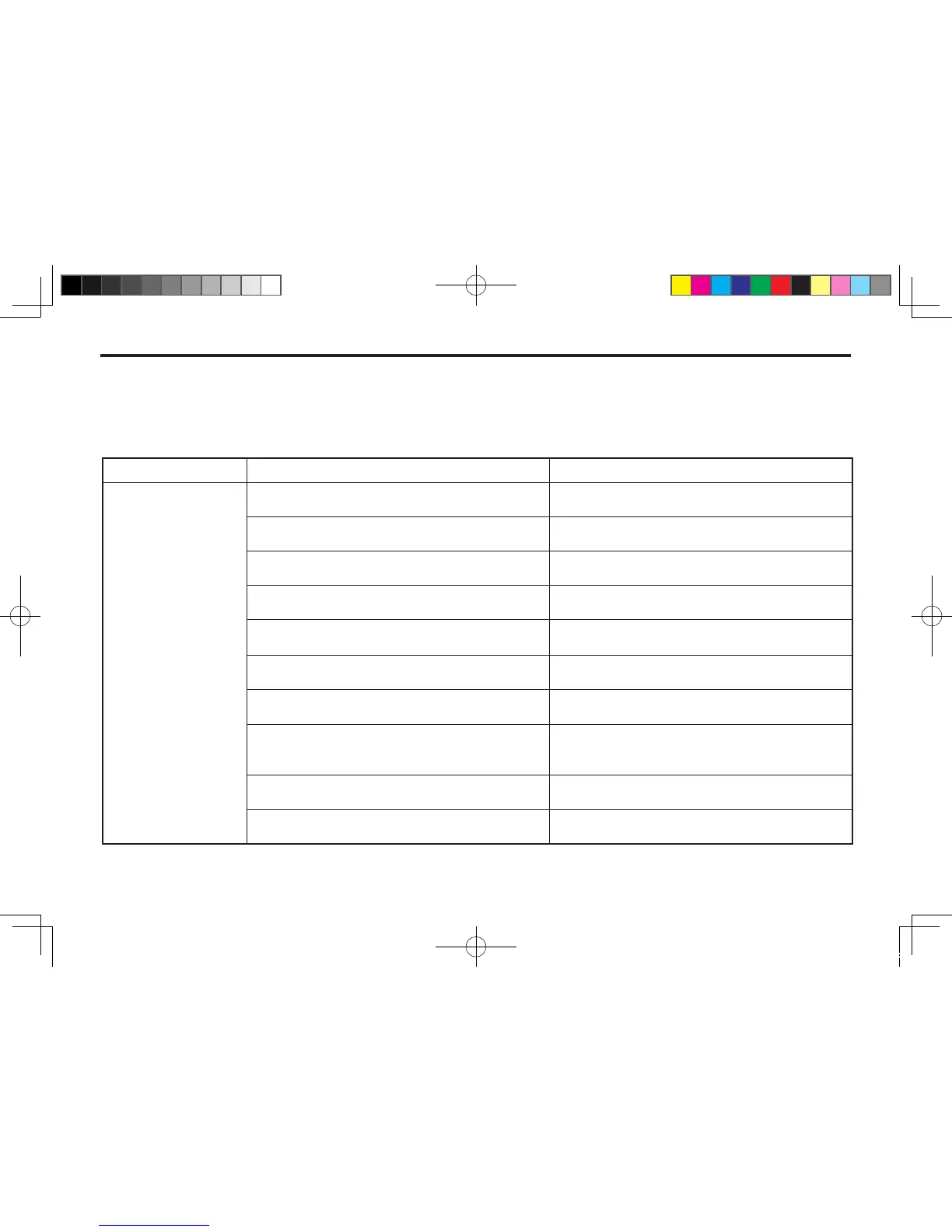

TROUBLE SHOOTING

This Trouble shooting Chart is provided for reference for possible loader operational problems. Determine the problem

that best describes the operational problem being experienced and eliminate the possible causes as listed by following

the correction procedures. For further assistance contact your dealer.

PROBLEM POSSIBLE CAUSE CORRECTION

1. Lift and Bucket cylin-

ders inoperative.

Low hydraulic uid level.

Check and replenish hydraulic uid.

Hydraulic hoses connected improperly.

Check and correct hydraulic hose connections

.

Hydraulic hoses to/from control valve blocked.

Check for damaged (kinked) hoses, etc.

Loader control valve or tractor main relief valve

stuck open.

Check system pressure. Repair or replace relief

valve.

Low system pressure supplied from hydraulic

pump.

Check system pressure. Repair or replace pump.

Control valve linkage broken.

Inspect. Repair as required.

Quick disconnect coupler(s) are not fully

connected or "Flow check".

Check coupler connections. Replace coupler(s)

if necessary.

Hydraulic hose or tubeline blockage.

Check for evidence of damage to hoses or

tubelines that would block ow of oil between

cylinders and control valve.

Cylinder piston assembly defective (not sealing).

Check cylinders for internal leakage as described

in service section under cylinder leakage tests.

Control valve blockage.

Inspect for blockage. Disassemble valve if neces-

sary.

Loading...

Loading...