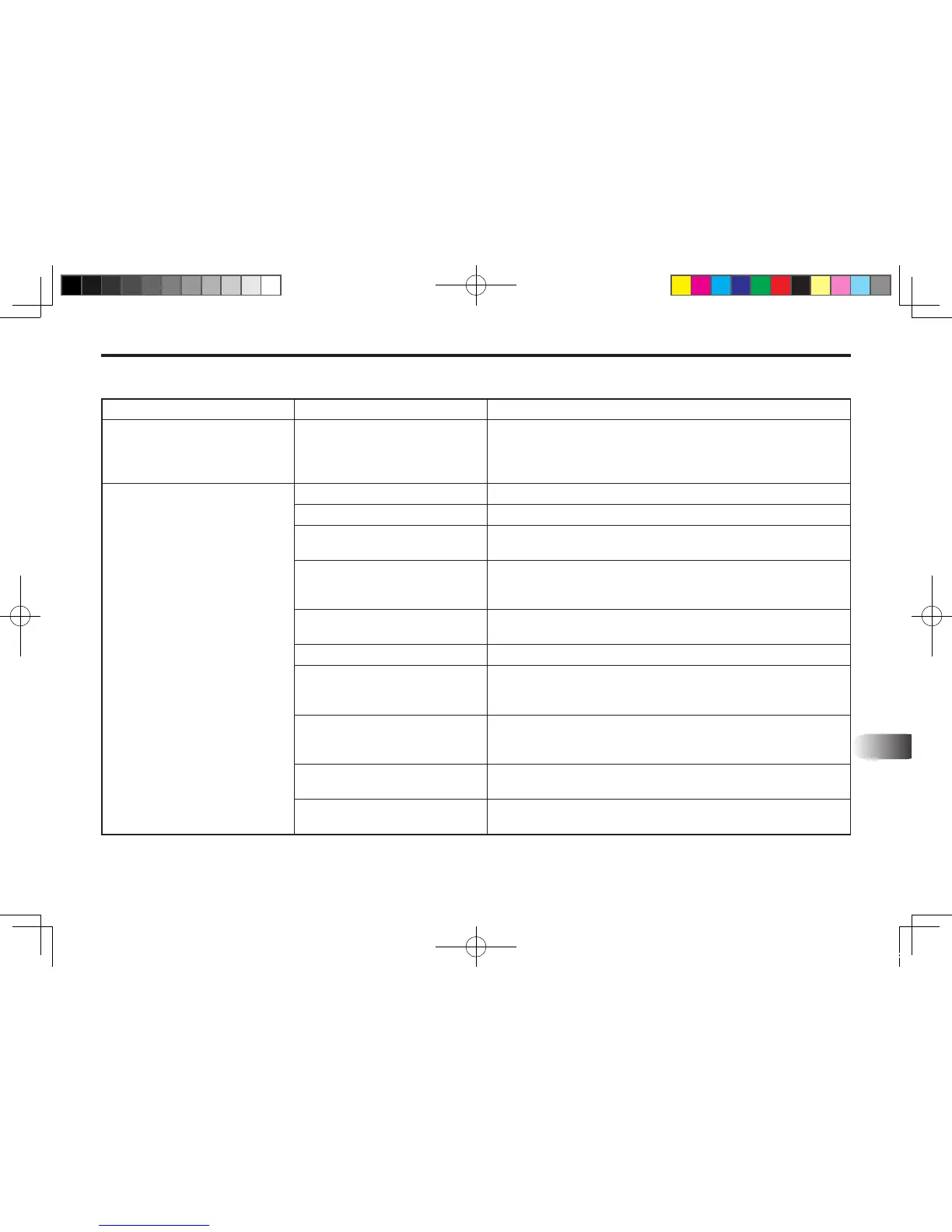

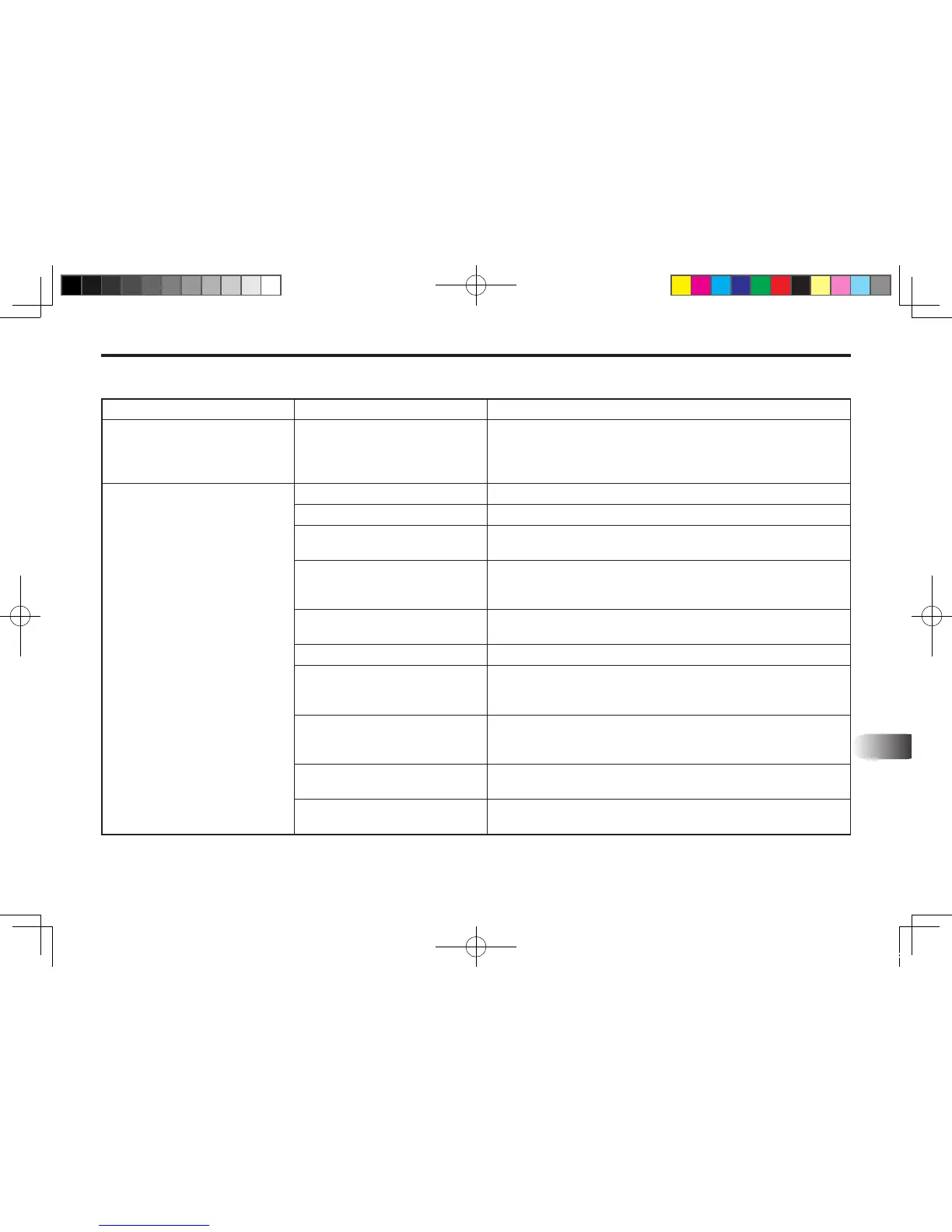

PROBLEM POSSIBLE CAUSE CORRECTION

2. Lift and/or bucket cylinders

operate in wrong direction

relative to control valve lever

position.

Hydraulic hoses connected

incorrectly.

Correct hydraulic hose connections.

3. Slow or erratic lift

Low hydraulic uid level.

Check and replenish hydraulic uid.

Cold hydraulic uid.

Allow hydraulic system to warm up to operating temperature.

Engine R.P.M. too slow (hy-

draulic pump R.P.M. too slow).

Increase engine speed to obtain satisfactory loader opera-

tion.

Excessive weight in bucket.

Material weight exceeds maxi-

mum specied loader capacity.

Reduce material load.

Control valve linkage binding/

defective.

Check control valve linkage and repair if worn/defective.

Aeration of hydraulic uid

Refer to "Aeration of Hydraulic Fluid."

Quick disconnect coupler

restriction or coupler "Flow

Checks"

Check coupler connections.

Repair or replace.

Hydraulic hose or tube-line

restriction (hoses/tube-line

kinked or pinched.)

Check hoses and tube-lines for evidence of restriction.

Lift cylinder piston assembly

leakage.

Check cylinders for leakage.

Repair as needed.

Relief valve erratic or set be-

low specications.

Check and reset relief valve setting as needed.

Loading...

Loading...