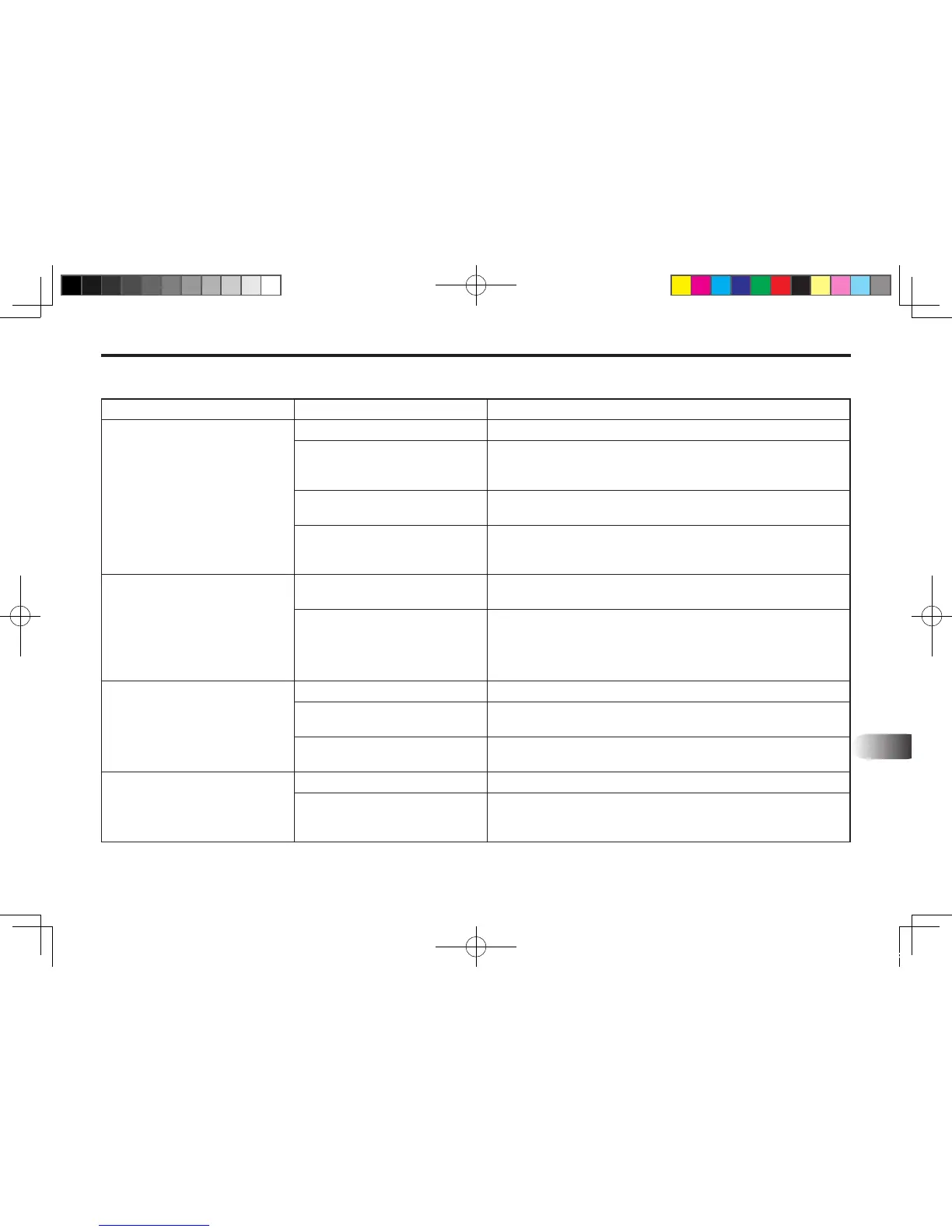

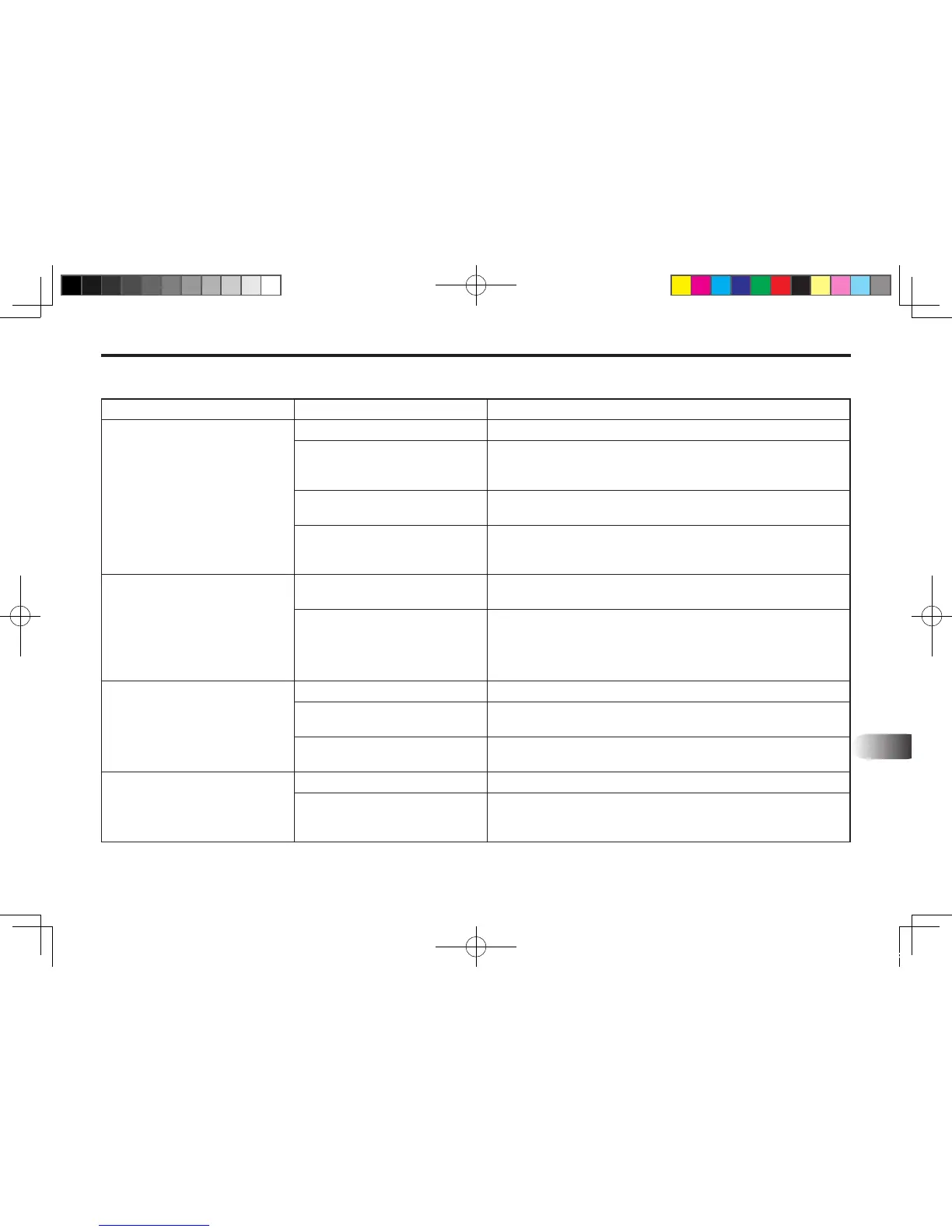

PROBLEM POSSIBLE CAUSE CORRECTION

6. System relief valve squeals.

Cold hydraulic uid.

Allow hydraulic uid to warm up to operating temperature.

Excessive load in bucket.

Weight exceeds specied

loader capacity.

Reduce load.

Relief valve setting below

specications.

Check and reset valve setting as needed.

Hydraulic hose, tube line or

quick disconnect coupler re-

striction.

Check for evidence of restriction in hydraulic oil ow. Repair

or replace defective components.

7. Loader drops with control

valve spool in "Centered"

position (no external oil

leakage evident.)

Note : A gradual drop over an

extended period of time is a

normal condition.

Cylinder piston assembly leak-

age.

Check cylinders for leakage.

Control valve internal leakage.

Replace control valve and recheck.

8. Control valve spool(s) will not

return to centered position.

Control lever linkage binding.

Determine origin of binding and repair.

Control valve spool centering

is broken.

Replace centering spring.

Control valve spool binding in

valve body spool bore.

Disassemble valve for inspection and repair.

9. External hydraulic uid

leakage.

Loose hydraulic connection.

Tighten loose connections.

Defective hydraulic hose, tube

line adapter tting & tting

O-ring.

Check for origin of oil leak and replace defective parts.

Loading...

Loading...