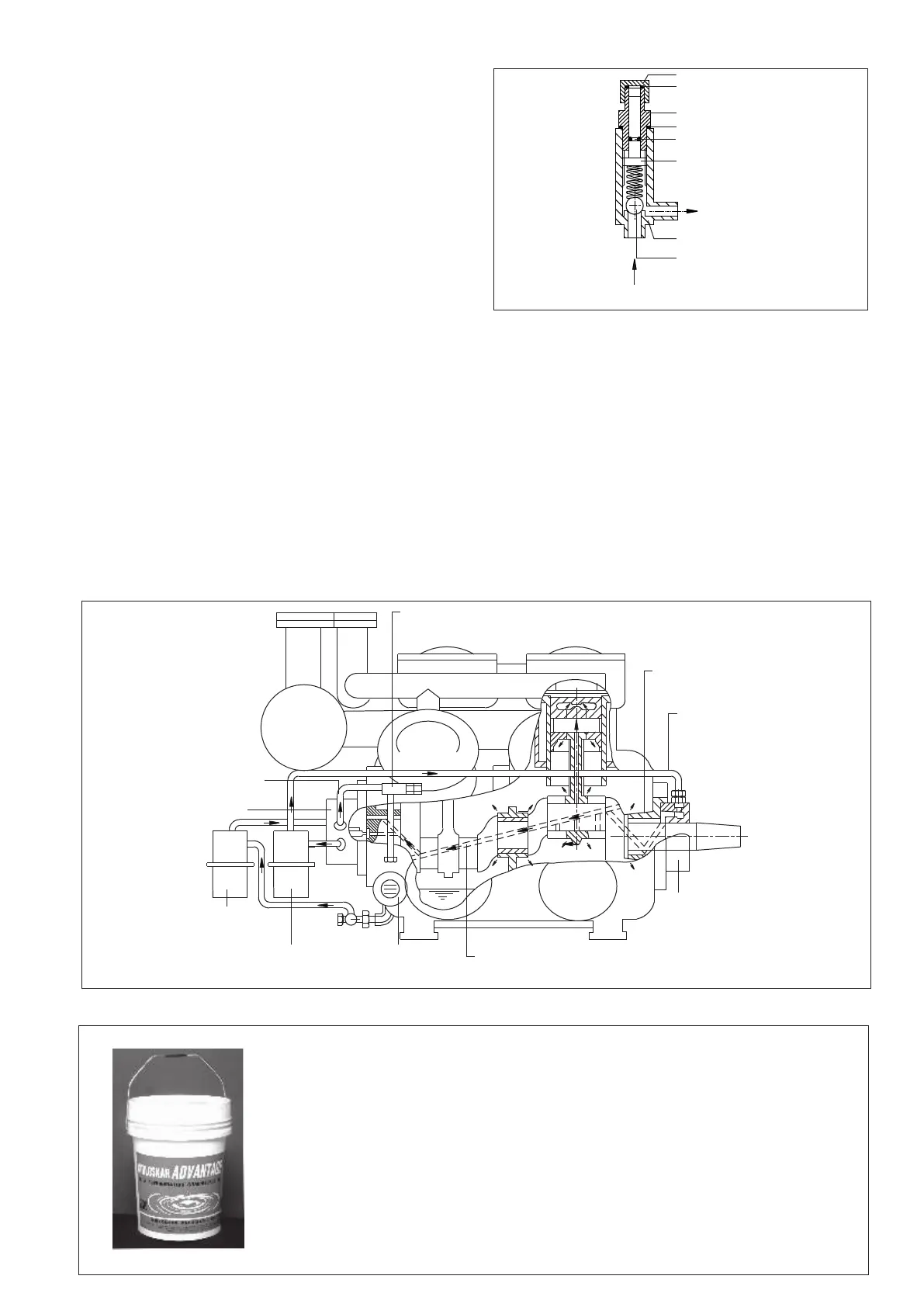

2.9 LUBRICATION DIAGRAM

The lubrication of the compressor is of the forced feed

type and effected by a gear pump driven from the

crankshaft. The oil circuit is shown in Fig. 5 & 6.

The oil enters the pump via the wire gauze suction oil

strainer. High pressure oil is fed to the differential

pressure regulator where the oil pressure is reduced and

is fed to shaft seal housing, via the paper type delivery

oil strainer, Oil reaches all main bearings, big end and

small end bearings via the internal ways in the

crankshaft and connecting rods. The thrust bearing of

the crankcase is lubricated via a separate oil way in the

bearing cover. Lubrication of the cylinder liners is

effected by surplus oil from the gudgeon pins and the big

ends. The arrows indicate the direction in which the oil

flows. Excess of the oil is led back, via a hole in

crankshaft to the oil pump housing from where to

externally fitted oil pressure regulator.

From the oil pressure regulator the oil is returned into

the crankcase behind the oil level glass, to complete the

lubrication circuit. A pressure gauge is connected to the

oil return line on oil pump before the oil pressure

regulator through a three way stop valve. To stop the

electric motor at the time of too low of oil pressure, one

oil pressure differential pressostat may be connected to

this 3-way stop valve. The oil pressure should be adjust-

ed by means of the oil pressure regulator & should be at

2

least 1.5 kg/cm higher than the crankcase pressure.

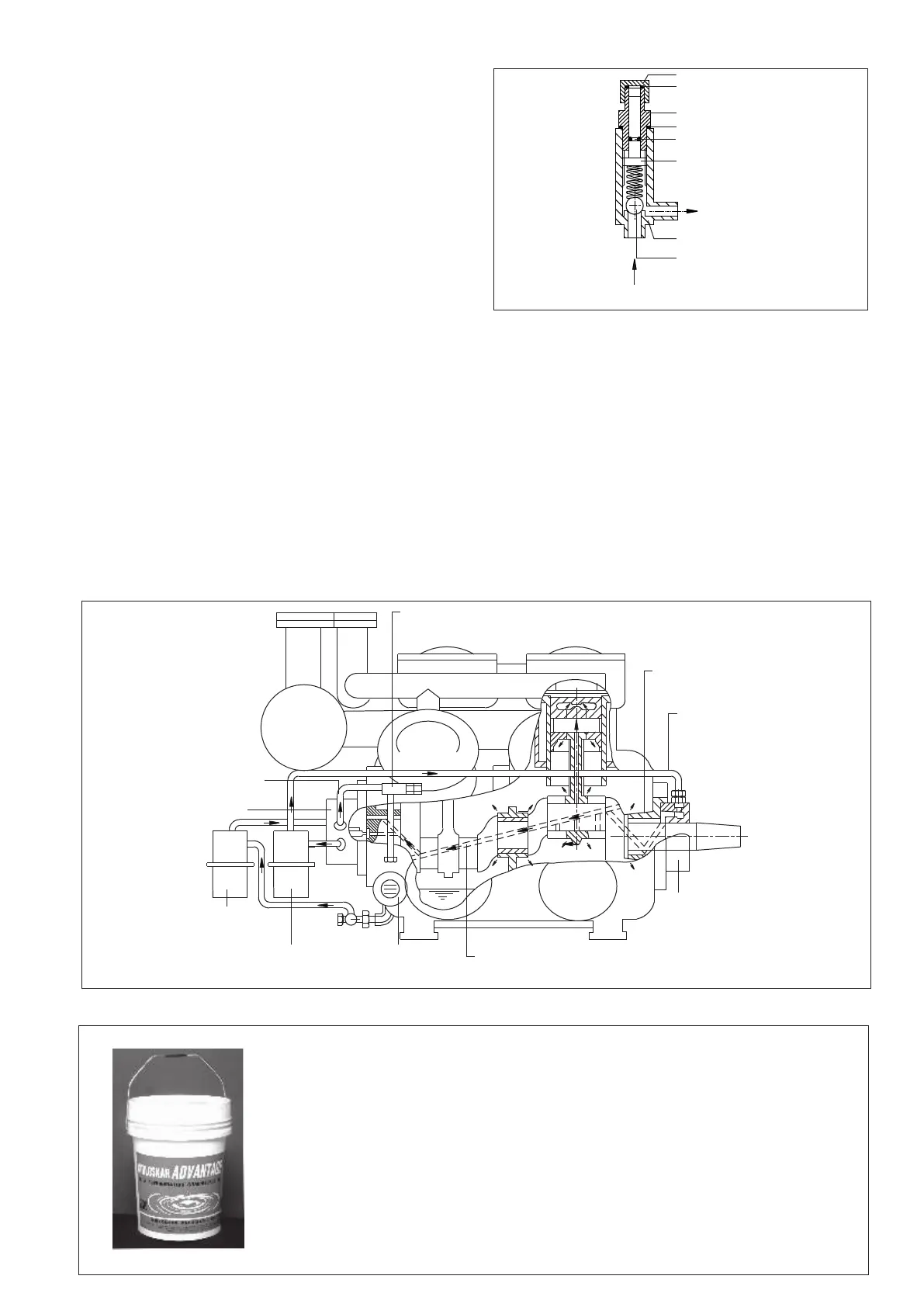

Figure 5 : Oil Pressure Regulator

The oil level and the oil return jet are visible through the

two level glasses, which are fitted at same level but in

opposite walls of the crankcase. The oil level should

always be visible in the oil level glass whilst it is not

advisable to let it rise above its centre line. For correct

lubricant to be used, refer lubricating chart.

2.10 PRESSURE EQUALIZING LINE

A pressure equalizing line is fitted between the suction

strainer housing and the crankcase. This line provides an

open connection between the crankcase and the suction

line, which is necessary for evacuating the gas from

crankcase before topping up the oil. It also prevents

pressure build up due to gas blow-by past the pistons.

Recommended Oil

KIRLOSKAR ADVANTAGE AC & REFRIGERATION COMPRESSOR OIL

n 20 ltr smart pack

n Easy to buy, stock and use

n No risk of loose purchased adulterated and reconditioned oil

n No need to invest on 200 ltr drum

n Grade ISOVG68

n Suitable for refrigerants NH3 and R22

n Evaporating temp. range: +10ºC to -25°C

Figure 6 : Lubrication System

LUBRICATING OIL PRESSURE REGUALTOR

OIL WAY TO

THRUST BEARING

EXTERNAL OIL

DISCHARGE

LINE

SHAFT SEAL

HOUSING

OIL CHANNEL IN CRANKSHAFTSIGHT GLASS

OIL DISCHARGE FILTER

OIL SUCTION

FILTER

OIL PUMP

EXTERNAL OIL

RETURN LINE

CAP

PACKING

NIPPLE

PACKING

O RING

SET PIN

TO OIL

LEVEL GLASS

VALVE HOUSING

BALL VALVE

7

Loading...

Loading...