Document No.:KE-4011-03 Page: 15/27

19. Disassembly and Reassembly of Actuators

19.1 When you disassemble or reassemble these actuators for inspection or maintenance, the utmost

care must be taken to respect the warnings and cautions mentioned here.

Before disassembly of spring cartridges from FBS actuator, evenly loosen all of 4

spring cover bolts ( but don’t completely remove them from the cover ) and check

if the spring has been released from the compression force and bolts can be

rotated by hand.

If the spring cover bolts are found too tight to be rotated by hand, the spring still

remains energized, possibly due to damage of the spring cartridge or the housing

pressure remaining higher than the atmospheric level. In such a case,

disassembly work must be immediately discontinued to prevent the spring

cartridge from jumping out.

If you have a concern of damage of a spring cartridge, securely retighten spring

cover bolts, and replace the actuator itself without removal of the spring cartridge.

Before disassembling, loosen the hexagon headed bolt under air port to

depressurize the housing.

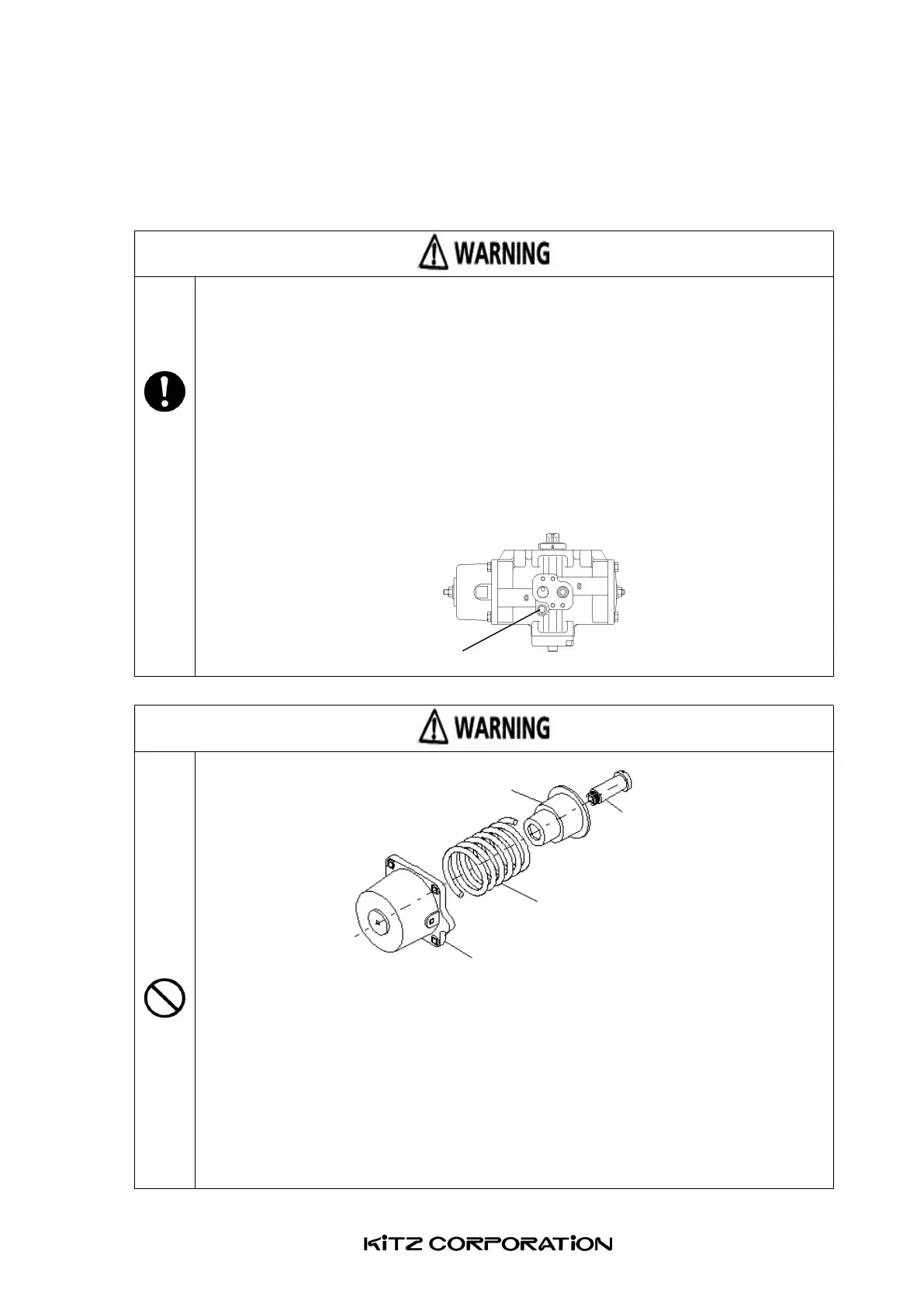

A compressed heavy-duty spring is packed in a spring cartridge of FBS spring

return actuator. Careless disassembly of the cartridge may cause the spring to

jump out and result in damage of properties or injury of personnel. Don’t loosen a

retainer guide from the spring retainer.

Don’t fall or step on a spring cartridge. Careless or rude handling may cause an

unintended separation of the highly energized spring from the cartridge.

Don’t remove an end cover from a pressurized actuator housing. Disassembly of

any energized actuator is forbidden.

Don’t use compressed air as the measure of disassembly of an actuator. A

piston may hazardously jump out.

Retainer guide

Spring retainer

Spring

Spring cover

Hexagon headed bolt

Loading...

Loading...