Document No.:KE-4011-03 Page: 6/27

11. Air Consumption

Air consumption means the volume (Q) of the air released to the atmosphere from an actuator operating

[n] times forward and backward per hour as converted to the average volume per minute. Decide the

capacity of an air compressor using the result of the following calculation. We recommend to use an air

reservoir of an adequate size to constantly operate an actuator at the preset time.

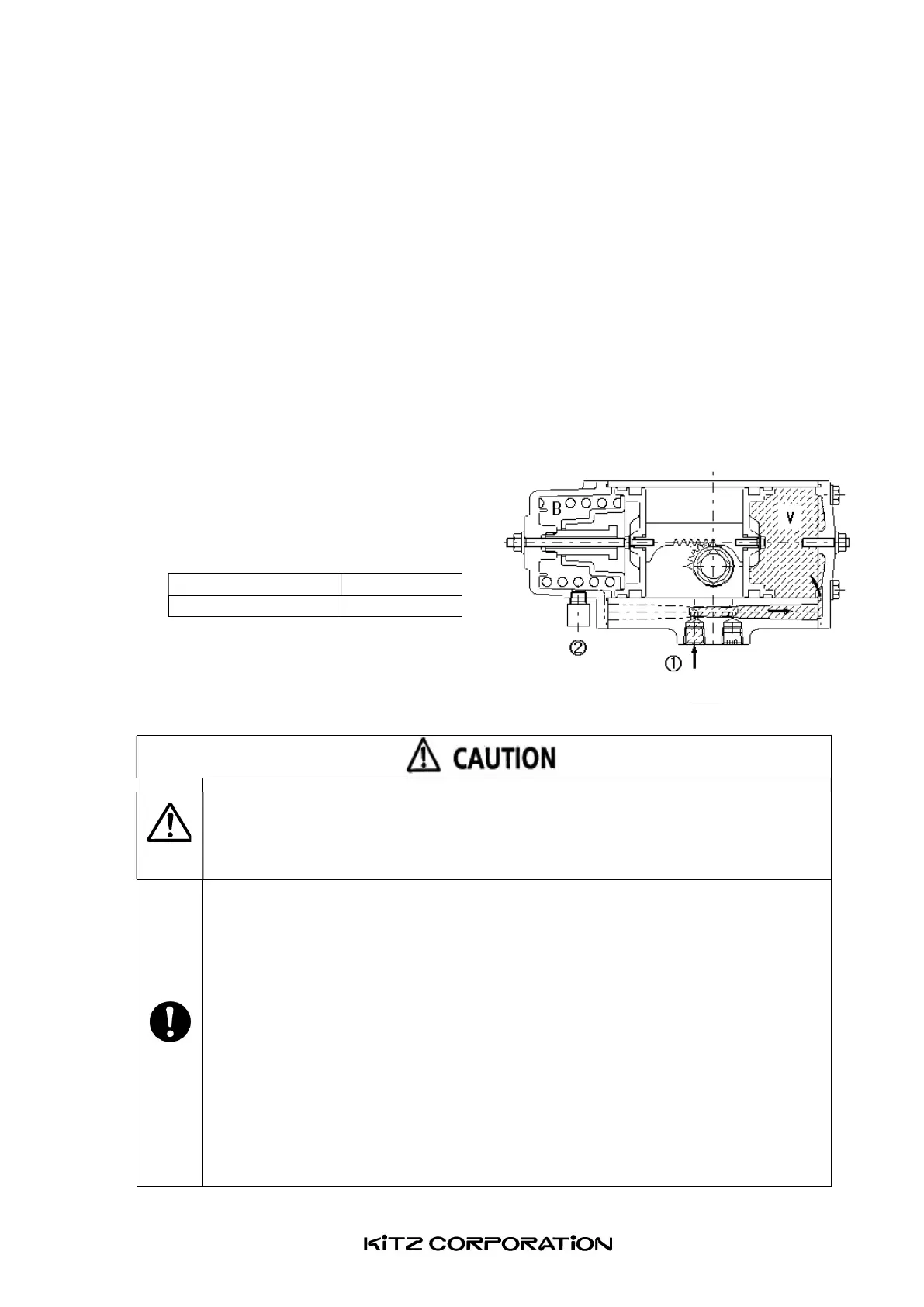

◆ Air consumption of FBS actuator:

Q = V (P + 0.1013) / 0.1013 x n/60 [L/min.(ANR)]

V: Volume of actuator housing [L]

Refer to Table 2 and the illustration shown below.

P: Air operation pressure [MPaG]

n: Number of operation cycles per hour

Table 2 Volume of actuator housing

Fig3

The required capacity of an air compressor depends on the availability and the

volume of an air reservoir, the number of hourly operations, the time required for

valve stroke and whether the air compressor is used exclusively or otherwise for

the actuator.

To decide the practical capacity of air compressors and reservoirs, adding some

extra 30% to the calculated air consumption volume is recommended to absorb

possible loss of air caused during a travel through air tubing and accessories.

Use an air-filter to continually supply clean, dry air to an actuator.

Use plastic tapes for tightly sealing piping connection, ensuring that tape ends do

not enter into the tube bore and block the port.

Also ensure that there is no leakage of air through all tubing connections.

Insufficient supply of air pressure causes malfunction or failure of an actuator.

Appropriately design the total length of air tubing. Too long air tubing causes

pressure loss or insufficient flow rate of the air, and results in malfunction or

failure of an actuator.

Actuator type V [L]

FBS-1 0.15

Loading...

Loading...