65

The purpose of a deep tillage tool is to fracture the compacted layer of soil beneath the surface

known as the hardpan. The hardpan, usually only a couple inches thick, prevents plant roots from

reaching moisture and nutrients below. The deep tillage tool is designed

to run 1”-2” below the hardpan, fracturing it and allowing plant roots

to reach the moisture and nutrients it needs. A probe, like the one shown

here, is used to determine how deep the hardpan is under the surface. To

use, insert the tip of the probe into the ground and add down pressure on

the handle until the probe gets hard to push. Mark the ground level on the

probe remove it from the ground. The distance from the tip of the probe

to the ground level mark is the distance to the hardpan. For accurate

results several measurements should be taken and averaged together. Once the depth of the hard pan is

determined the machine depth can be set 1in-2in below this depth.

*Note: Maximum shank depth below surface is 18in.

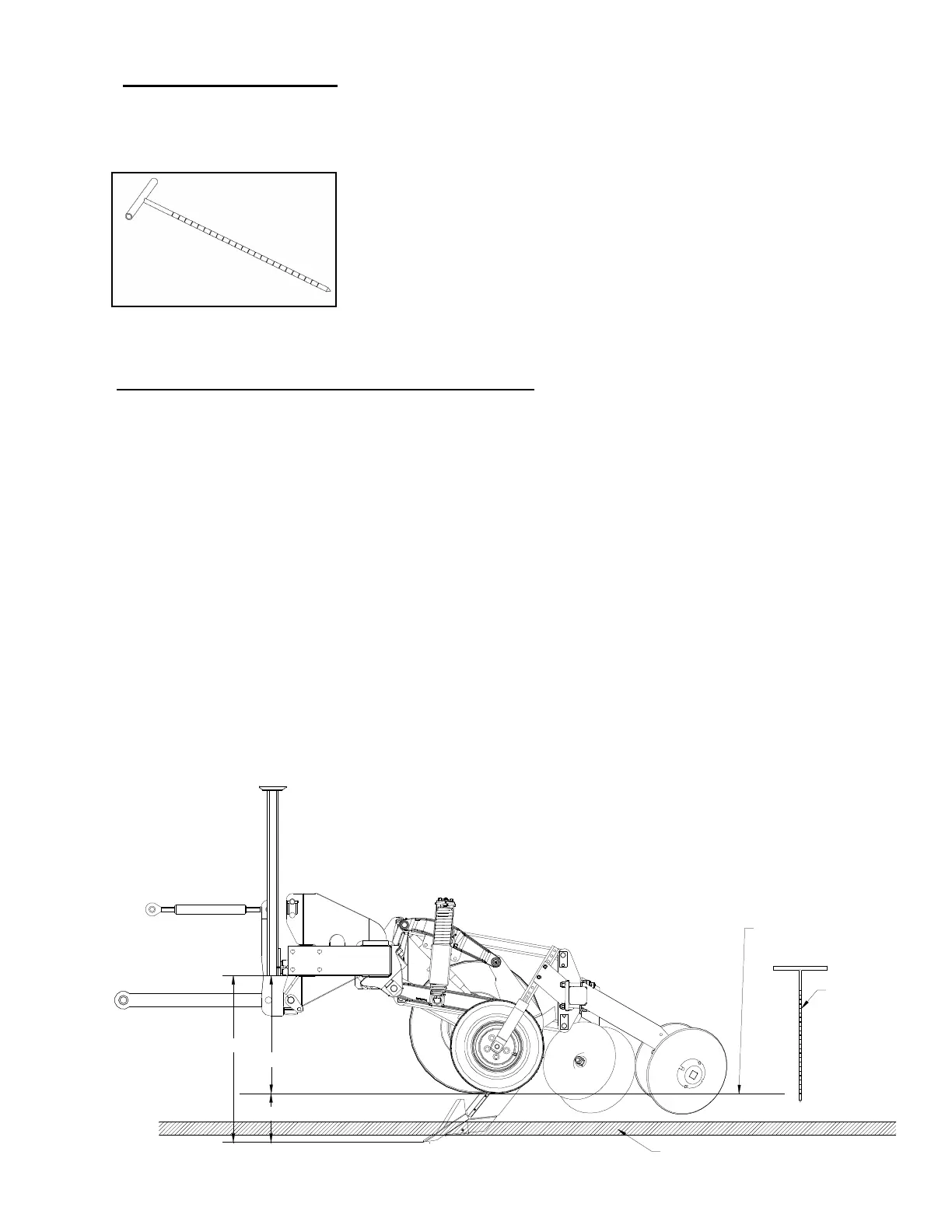

Setting Operating Depth

1) Set the machine on a level surface with shank points just touching the ground.

2) Measure the distance from the level surface to the bottom surface of the toolbar gauge wheel. (This

will be the approximate operating depth (D))

3) Adjust turnbuckles on Gauge Wheels until the desired depth is set.

4) Take the implement to the field and pull the shanks into the ground until the Gauge Wheel is

supporting the rear of the machine.

5) Measure the distance from the bottom of the toolbar to the ground to get the toolbar height.

6) Subtract this number from 37 to determine the actual working depth of the shanks. (It is 37in from

the bottom of the toolbar to the point on the shank.

7) Raise implement slightly and adjust Gauge Wheel as needed to set desired working depth.

Depth of Penetration

HARDPAN

37

H

D

GROUND LEVEL

PROBE

DEPTH (D)= 37- HEIGHT (H)

Loading...

Loading...