7/11/2005 VERSION 2.0 17

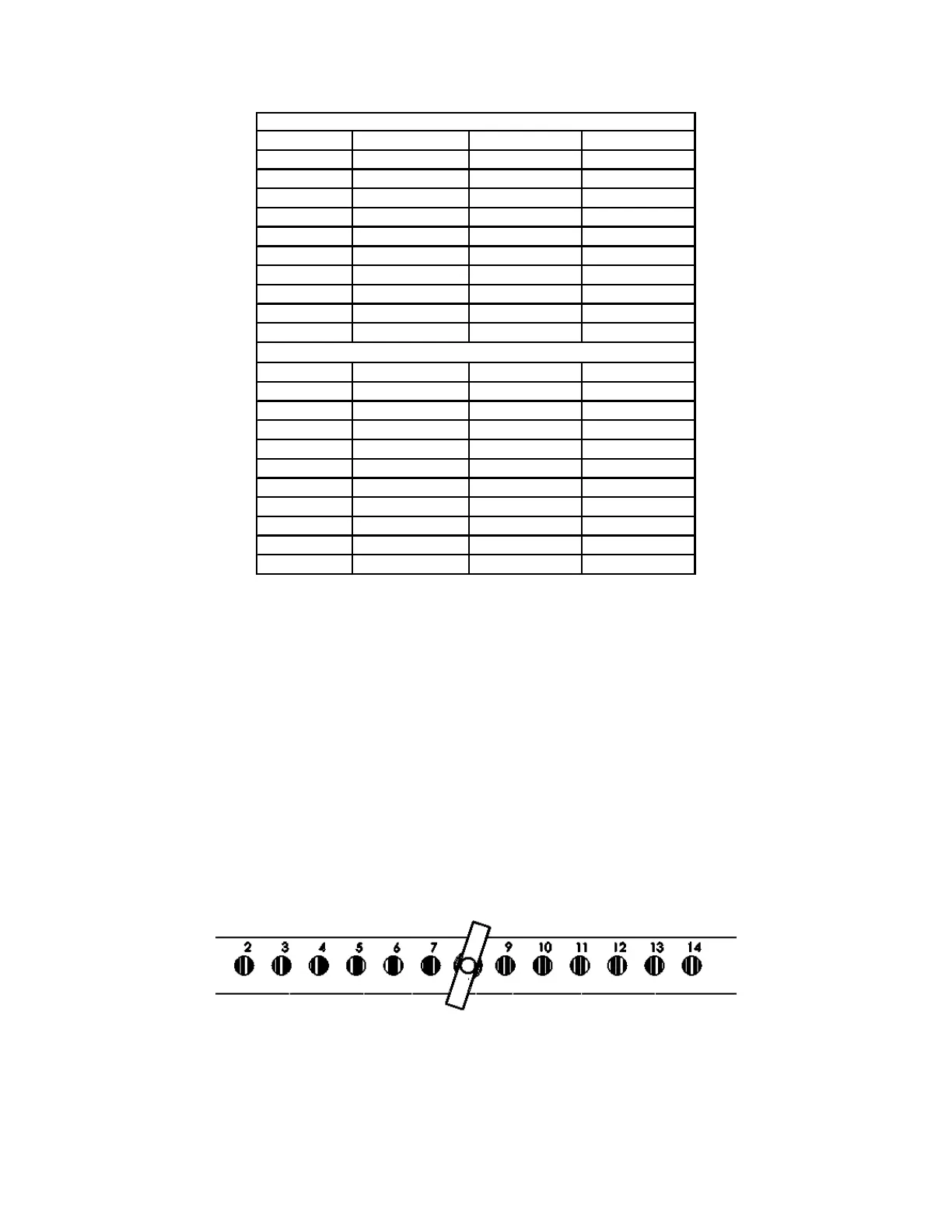

Elbow Size Bend Degress Blank Length Blank Length

"A" Elbows 45 8.5 in 216 mm

60 10 in 254 mm

75 11.5 in 292 mm

90 12.5 in 318 mm

"B" Elbows 30 8.5 in 216 mm

45 10 in 254 mm

60 11.5 in 292 mm

75 12.5 in 318 mm

90 14 in 356 mm

Elbow Size Bend Degress Blank Length Blank Length

"A" Elbows 45 9 in 229 mm

60 10.5 in 267 mm

75 12 in 305 mm

90 13 in 330 mm

"B" Elbows 30 9 in 229 mm

45 10.5 in 267 mm

60 12 in 305 mm

75 13 in 330 mm

90 14.5 in 368 mm

2-in x 3-in Downspout Blanks

3-in x 4-in Downspout Blanks

9.2.1. Profile vs. Number of Crimps

In general, two crimps account for approximately 25 degrees of bend in 2 x 3-in downspout. In the case of

3 x 4-in blanks two crimps account for approximately 15 degrees of bend. By adjusting the crimp depth

and position of the knives, it is possible to change these numbers by a crimp or two and still retain

acceptable elbows.

*These numbers will vary from machine to machine. They are provided as a guideline. *

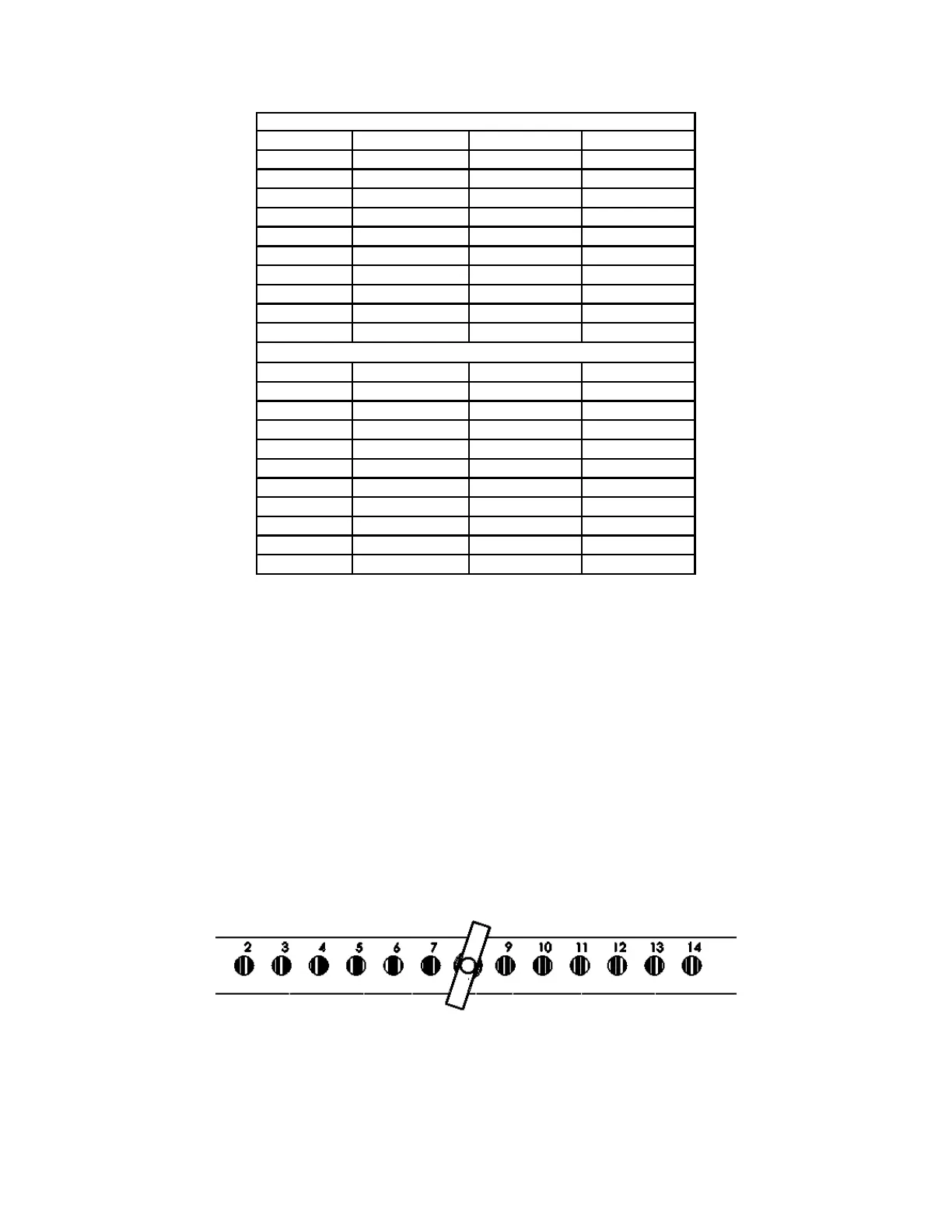

9.2.2. Setting the Number of Crimps

The machine will be set up and adjusted for a specific downspout size at the factory. The desired angle is

dependant upon the number of crimps. The numbers running across the top of the enclosure indicate the

number of crimps. Place the T-handle pin in the required hole. When the blank is inserted, the T-handle

pin will stop the advance assembly from sliding back any further and producing an elbow with too many

crimps.

Figure 9-1: Placement of the T-Handle pin determines the number of crimps.

Loading...

Loading...