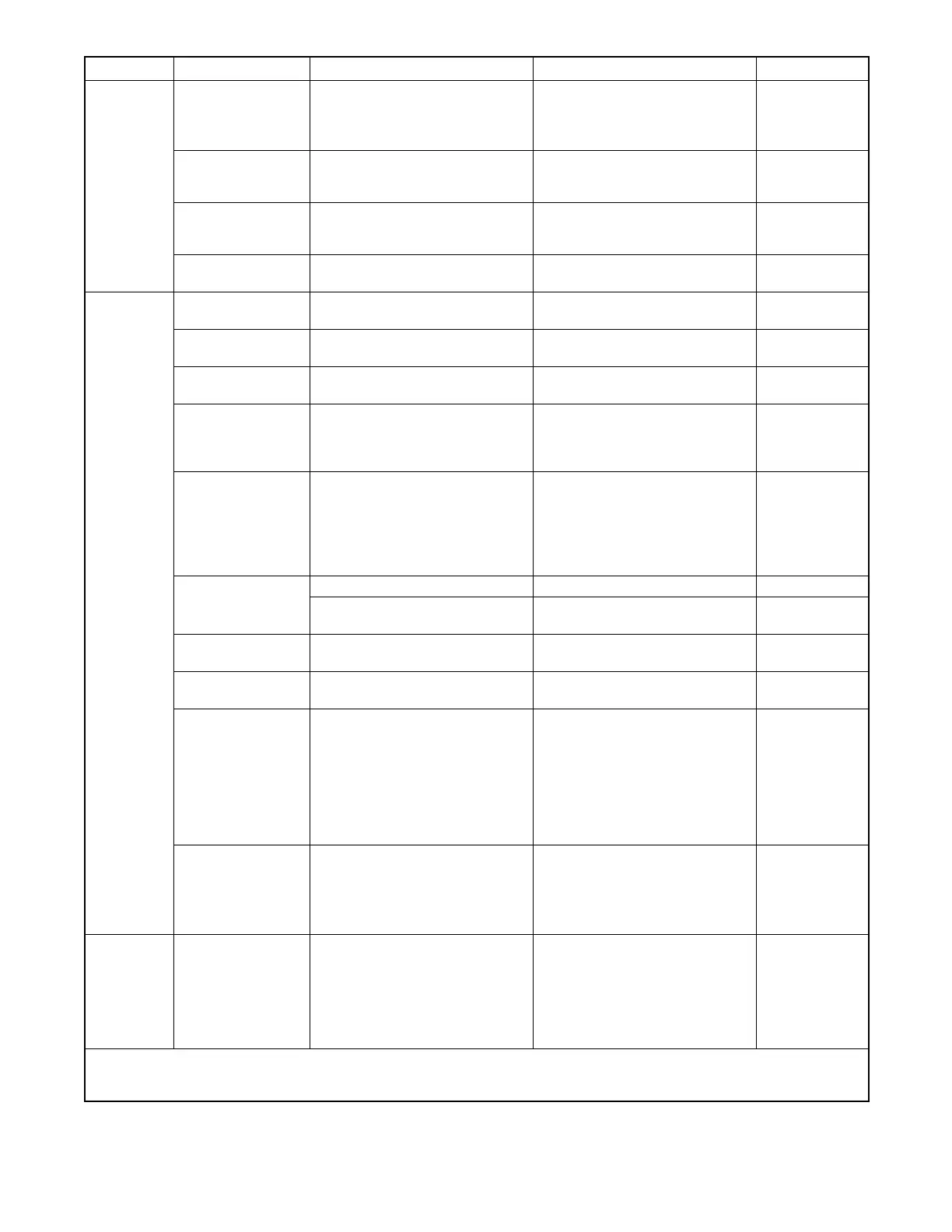

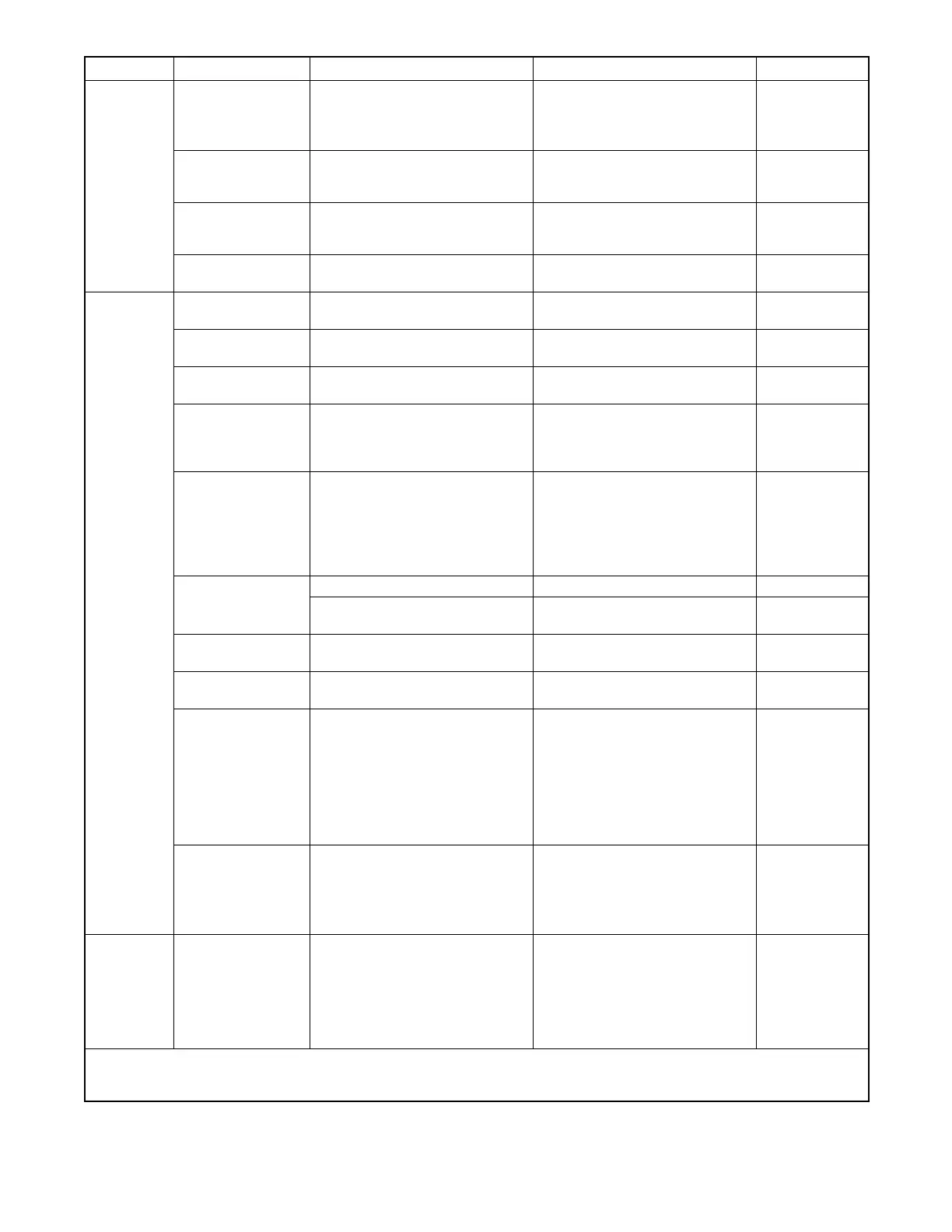

TP-6519 8/17 31Section 3 Troubleshooting

Problem ReferenceCorrective ActionTestPossible Cause

Lacks

power,

continued

Engine not running

at rated rpm

Check controller settings for unit

configuration (UC) and engine

type (EC). *

Check engine speed.

Reset controller settings for unit

configuration (UC) and engine

type (EC). *

Adjust engine speed.

Section 4.5

Engine power loss Refer to the engine service

manual for troubleshooting and

repair instructions.

Refer to the engine service

manual for troubleshooting and

repair instructions.

Engine S/M

Governor

malfunction or

misadjustment

Test governor. Adjust governor. Section 5.9

Ignition system See the engine service manual for

service procedures.

See the engine service manual for

service procedures.

Engine S/M

Low output

or

excessive

drop in

voltage

Generator

overloaded

Reduce electrical load and check

operation.

Unplug some lights or appliances

connected to the generator set.

—

Incorrect controller

configuration

Check the controller configuration

parameters. *

Adjust the controller configuration

parameters. *

Section 4.5

Incorrect controller

voltage settings

Check the controller voltage

settings. *

Adjust the controller voltage

settings. *

Section 4.5.4

Alternator or control

system

Perform separate excitation

procedure to isolate problem to

the alternator or the control

system.

Troubleshoot the alternator or

control system as indicated by

test results.

Section 5.2

SCR module Check wiring and connections to

the SCR module.

Check auxiliary winding fuse F1

(lead 55).

Replace SCR module and

recheck voltage.

Tighten connections and/or

replace wiring as required.

Replace auxiliary winding fuse F1

(lead 55).

Replace SCR module and

recheck voltage.

Section 7

Section 5.13.2

Section 4.8

Controller

Check the controller settings. Adjust controller settings. Section 4.5

Test the controller as described in

Section 3.4.

See Section 3.4. Section 3.4

Rotor Test rotor for open, grounded, or

shorted windings.

Replace rotor if faulty windings

are found.

Section 5.4

Stator Test stator for open, grounded, or

shorted windings.

Replace stator if faulty windings

are found.

Section 5.3

Brush connection Check for loose brush

connections.

Check for loose brush mounting.

Check the resistance through the

brushes. Resistance through the

brushes should be low, 0.1--0.2

ohms without meter lead

resistance.

Tighten loose brush connections.

Tighten mounting screws.

Replace brushes if they show

uneven wear or are worn to

one-half their original length.

Section 5.6

Low engine speed

causing voltage

roll-off

Check system voltage/frequency

(Uu) and engine type (Ec)

parameters. *

Check engine speed.

Engine problem.

Change system voltage/frequency

(Uu) and engine type (Ec)

parameters if not correct. *

Adjust engine speed.

Troubleshoot the engine.

Section 4.5.1

Section 4.5.4

Engine S/M

No output

voltage

AC output circuit

breaker open

Check for AC voltage on the

generator side of circuit breaker.

If there is AC voltage on the

generator side of the breaker,

then a problem in the load circuits

is causing the line circuit breaker

to trip.

Check for and correct short

circuits or overloading on the load

side before resetting the circuit

breaker.

—

* ADC-RES controller only. The DC-RET controller settings cannot be adjusted in the field.

W/D = Wiring Diagram(s) (Section 7) S/S = Generator Set Specification Sheet O/M = Generator Set Operation Manual

I/M = Generator Set Installation Manual Engine S/M = Engine Service Manual

Loading...

Loading...