FIGURE 8 -- COOLING AIR CIRCULATION

IGNITION SYSTEM

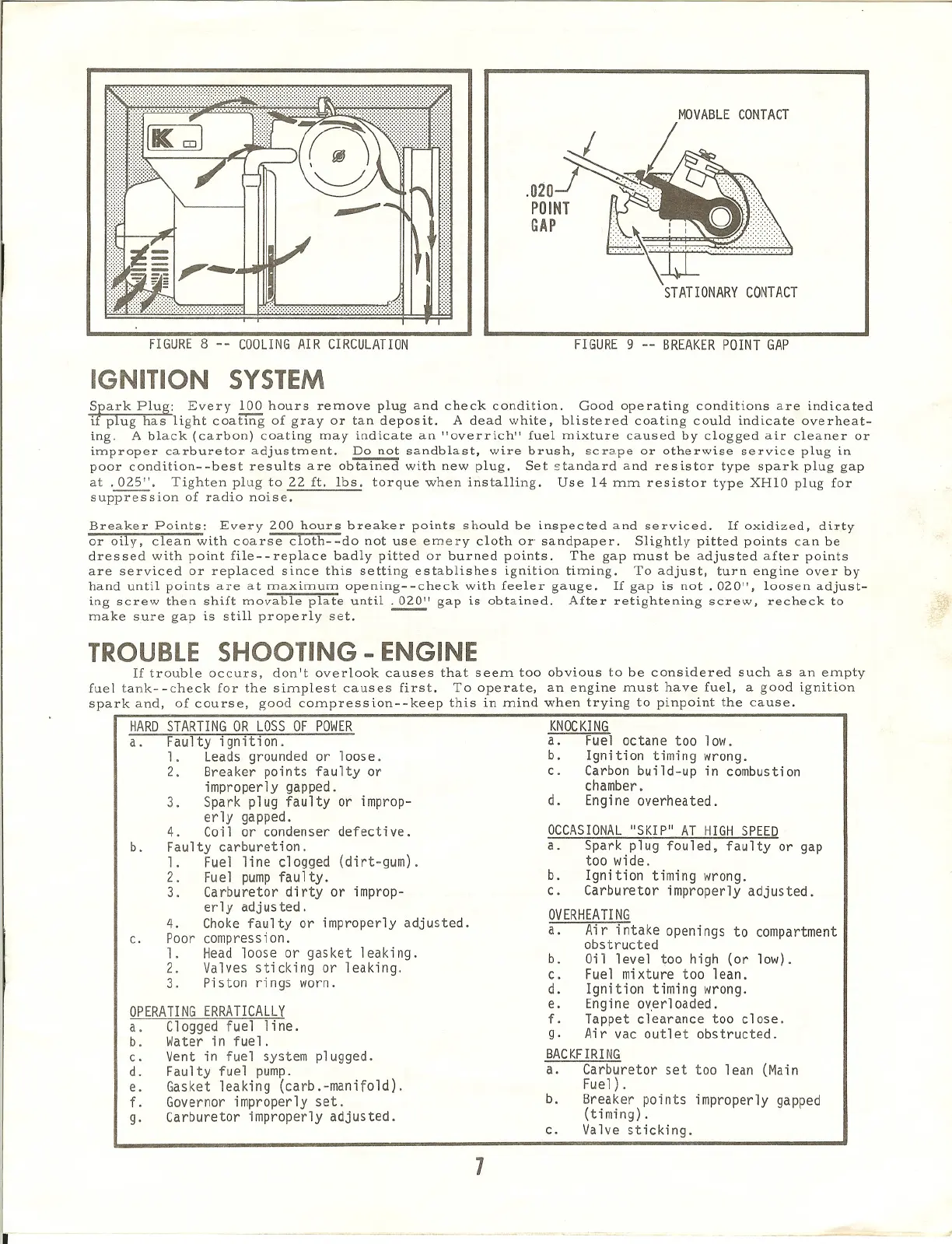

FIGURE 9 -- BREAKER POINT GAP

Spark Plug: Every 100 hours remove plug and check condition. Good operating conditions are indicated

1£ plug has light coating of gray or tan deposit. A dead white, blistered coating could indicate overheat-

ing. A black (carbon) coating may indicate an "overrich" fuel mixture caused by clogged air cleaner or

improper carburetor adjustment. Do not sandblast, wire brush, scrape or otherwise service plug in

poor condition--best results are obtained with new plug. Set standard and resistor type spark plug gap

at .025". Tighten plug to 22 ft. lbs. torque when installing. Use 14 mm resistor type XH10 plug for

suppression of radio noise.

Breaker Points: Every 200 hours breaker points should be inspected and serviced. If oxidized, dirty

or oily, clean with coarse cloth--do not use emery cloth or- sandpaper. Slightly pitted points can be

dressed with point file--replace badly pitted or burned points. The gap must be adjusted after points

are serviced or replaced since this setting establishes ignition timing. To adjust, turn engine over by

hand until points are at maximum opening--check with feeler gauge. If gap is not. 020", loosen adjust-

ing screw then shift movable plate until. 020" gap is obtained. After retightening screw, recheck to

make sure gap is still properly set. ---

TROUBLE SHOOTING - ENGINE

If trouble occurs, don't overlook causes that seem too obvious to be considered such as an empty

fuel tank--check for the simplest causes first. To operate, an engine must have fuel, a good ignition

spark and, of course, good compression--keep this in mind when trying to pinpoint the cause.

I

HARD STARTING OR LOSS OF POWER

a. Faulty ignition.

1. Leads grounded or loose.

2. Breaker points faulty or

improperly gapped.

3. Spark plug faulty or improp-

erly gapped.

4. Coil or condenser defective.

b. Faulty carburetion.

1. Fuel line clogged (dirt-gum).

2. Fuel pump faulty.

3. Carburetor dirty or improp-

erly adjusted.

4. Choke faulty or improperly adjusted.

c. Poor compression.

1. Head loose or gasket leaking.

2. Valves sticking or leaking.

3. Piston rings worn.

OPERATING ERRATICALLY

a. Clogged fuel line.

b. Water in fuel.

c. Vent in fuel system plugged.

d. Faulty fuel pump.

e. Gasket leaking (carb.-manifold).

f. Governor improperly set.

g. Carburetor improperly adjusted.

7

KNOCKING

a. Fuel octane too low.

b. Ignition timing wrong.

c. Carbon build-up in combustion

chamber.

d. Engine overheated.

OCCASIONAL "SKIP" AT HIGH SPEED

a. Spark plug fouled, faulty or gap

too wide.

b. Ignition timing wrong.

c. Carburetor improperly adjusted.

OV ERHEA II NG

a. Ai r intake openi ngs to compartment

obstructed

b. Oil 1eve 1 too high (or low).

c. Fuel mixture too lean.

d. Ignition timing wrong.

e. Engine overloaded.

f. Tappet clearance too close.

g. Air vac outlet obstructed.

BACKFIRING

a. Carburetor set too lean (Main

Fue 1) .

b. Breaker points improperly gapped

(timing) .

c. Valve sticking.

Loading...

Loading...