GENERATOR SERVICE

Generators do not normally require service on a regular basis; however, it is a good idea to

remove the end cover and check the commutator and brushes at least every six months or every 50

hours or more often under dusty, dirty conditions. Make a visual check of the commutator first--if a

thin skinlike film of uniform thickness is evident on the surface, this usually indicates normal operation

--this film acts as a lubricant and promotes longer brush life. If the surface is streaked or has ridges

of dirt, clean it with a coarse cloth or, if this doesn't work, use fine sandpaper or a commutator stone--

do not use emery cloth. Lift brushes and check surface--replace brush if unevenly worn or when worn

~to about 1/2". Use genuine Kohler replacement brushes only--substitutes may not be of correct

material and will wear out rapidly or cause commutator damage. Other common causes for rapid brush

wear are wrong brush tension, rough commutator surface, high mica on commutator and brush chatter.

Blow dust out with

i!.l. compressed air after servicing generator.

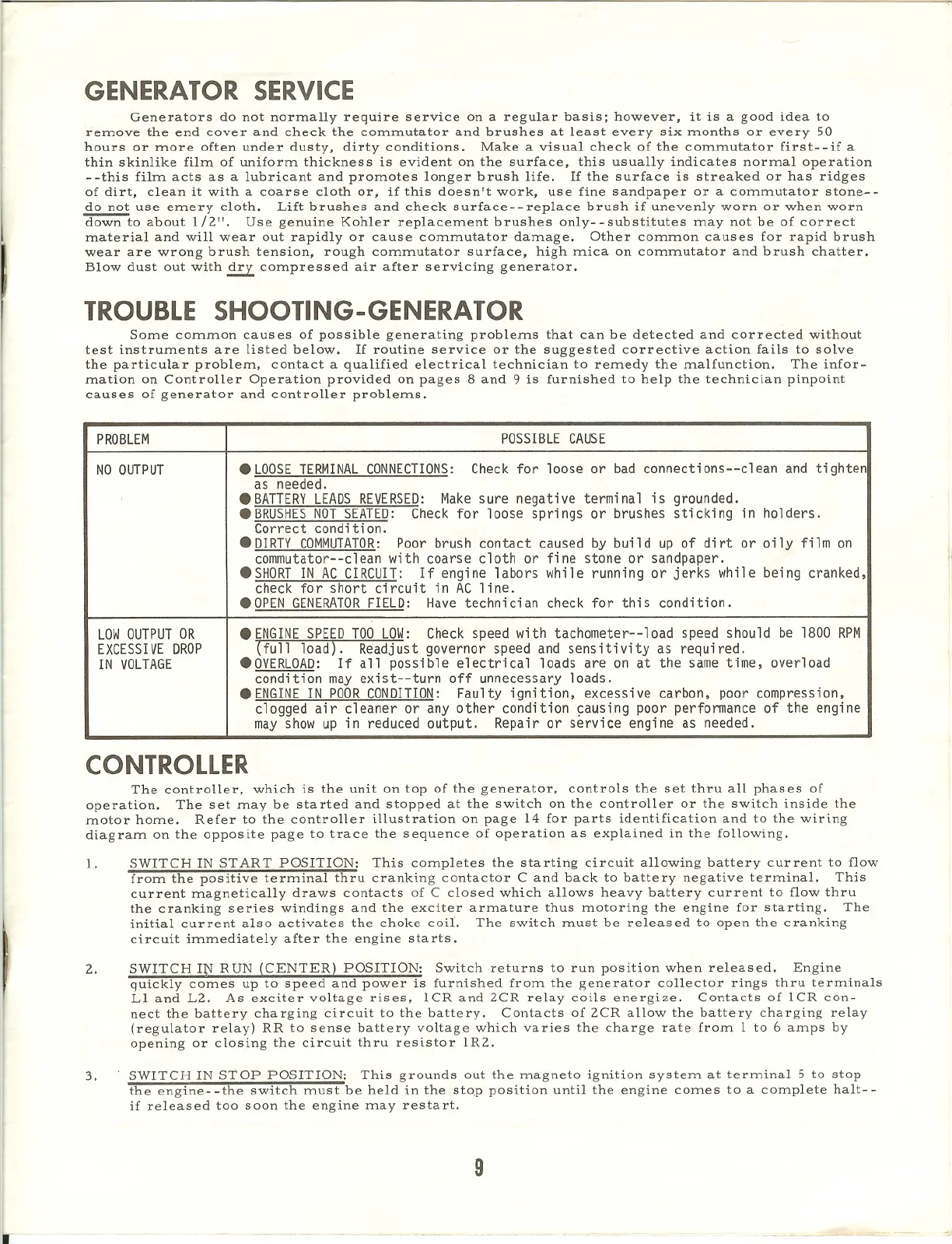

TROUBLE SHOOTING-GENERATOR

Some common causes of possible generating problems that can be detected and corrected without

test instruments are listed below. If routine service or the suggested corrective action fails to solve

the particular problem, contact a qualified electrical technician to remedy the malfunction. The infor-

mation on Controller Operation provided on pages 8 and 9 is furnished to help the technician pinpoint

causes of generator and controller problems.

PROBLEM

POSSIBLE CAUSE

NO OUTPUT

• LOOSE TERMINAL CONNECTIONS:

Check for loose or bad connections--clean and tighten

as needed. • BATTERY LEADS REVE RSED:

Make sure negative terminal is grounded.

• BRUSHES NOT SEATED:

Check for loose springs or brushes sticking in holders.

Correct condition.

• DIRTY COMMUTATOR:

Poor brush contact caused by build up of dirt or oily film on

commutator--clean with coarse cloth or fine stone or sandpaper.

• SHORT IN AC CI RCUIT:

If engine labors while running or jerks while being cranked,

check for short circuit in AC line.• OPEN GENERATOR FIELD:

Have technician check for this condition.

LOW OUTPUT OR

• ENGINE SPEED TOO LOW:

Check speed with tachometer--load speed should be 1800 RPM

EXCESSI VE DROP

(full load).

Readjust governor speed and sensitivity as required.

IN VOLTAGE

• OVERLOAD:

If all possible electrical loads are on at the same time, overload

condition may exist--turn off unnecessary loads .• ENGINE IN POOR CONDITION: Faulty ignition, excessive carbon, poor compression,clogged air cleaner or any other condition ~ausing poor performance of the enginemay show up in reduced output.

Repair or service engine as needed.

CONTROLLER

The controller, which is the unit on top of the generator, controls the set thru all phases of

operation. The set may be started and stopped at the switch on the controller or the switch inside the

motor horne. Refer to the controller illustration on page 14 for parts identification and to the wiring

diagram on the opposite page to trace the sequence of operation as explained in the following.

1.

2.

SWITCH IN STAR T POSITION: This completes the starting circuit allowing battery current to flow

from the positive terminal thru cranking contactor C and back to battery negative terminal. This

current magnetically draws contacts of C closed which allows heavy battery current to flow thru

the cranking series windings and the exciter armature thus motoring the engine for starting. The

initial current also activates the choke coil. The switch must be released to open the cranking

circuit immediately after the engine starts.

SWITCH I~ RUN (CENTER) POSITION: Switch returns to run position when released. Engine

quickly comes up to speed and power is furnished from the generator collector rings thru terminals

Ll and L2. As exciter voltage rises, lCR and 2CR relay coils energize. Contacts of lCR con-

nect the battery charging circuit to the battery. Contacts of 2CR allow the battery charging relay

(regulator relay) RR to sense battery voltage which varies the charge rate from 1 to 6 amps by

opening or closing the circuit thru resistor lR2.

.--

3. SWITCH IN STOP POSITION: This grounds out the magneto ignition system at terminal 5 to stop

the engine- -the switch must be held in the stop position until the engine comes to a complete halt--

if released too soon the engine may restart.

9

Loading...

Loading...