TP-5982 4/06 27Section 5 Fuel System

5.3.2 15/20C and 12.5/16CF Models

Conform to USCG regulations regarding in-line fuel

filters or strainers. Independently mount the in-line fuel

filter or strainer to the craft’s structure. Ensure

accessibility for servicing without removing permanent

structures.

Note: Fuel filter/strainer installation. Support each

fuel filter and strainer on the engine or boat

structure independent of its fuel-line connections

unless the fuel filter or strainer is inside a fuel

tank.

5.4 Antisiphon Device Installation

Install antisiphon devices when a fuel line section lies

below the highest point of the fuel tank. Install an

antisiphon device as follows:

D Use a spring-loaded check valve (tested to function

with the installation’s siphon head) or an electrically

operated shutoff valve (UL ignition-protected

tested to USCG regulations) that can operate

manually as the antisiphon device.

D Install the check valve above the fuel tank’s highest

point.

D Secure the check valve to the craft’s structure,

ensuring accessibility without removing permanent

structures.

D Locate the fuel-line section between the tank and

check valve above the fuel tank’s highest point.

Install an electric shutoff valve at the fuel tank’s

fuel-withdrawal fitting.

D Wire the shutoff valve to open whenever cranking

or running the generator set.

Antisiphon holes drilled into fuel dip tubes within the fuel

tank are unreliable antisiphon devices because they

become ineffective when restricted by dirt or gum.

5.5 Fuel Pump Lift and Fuel

Consumption

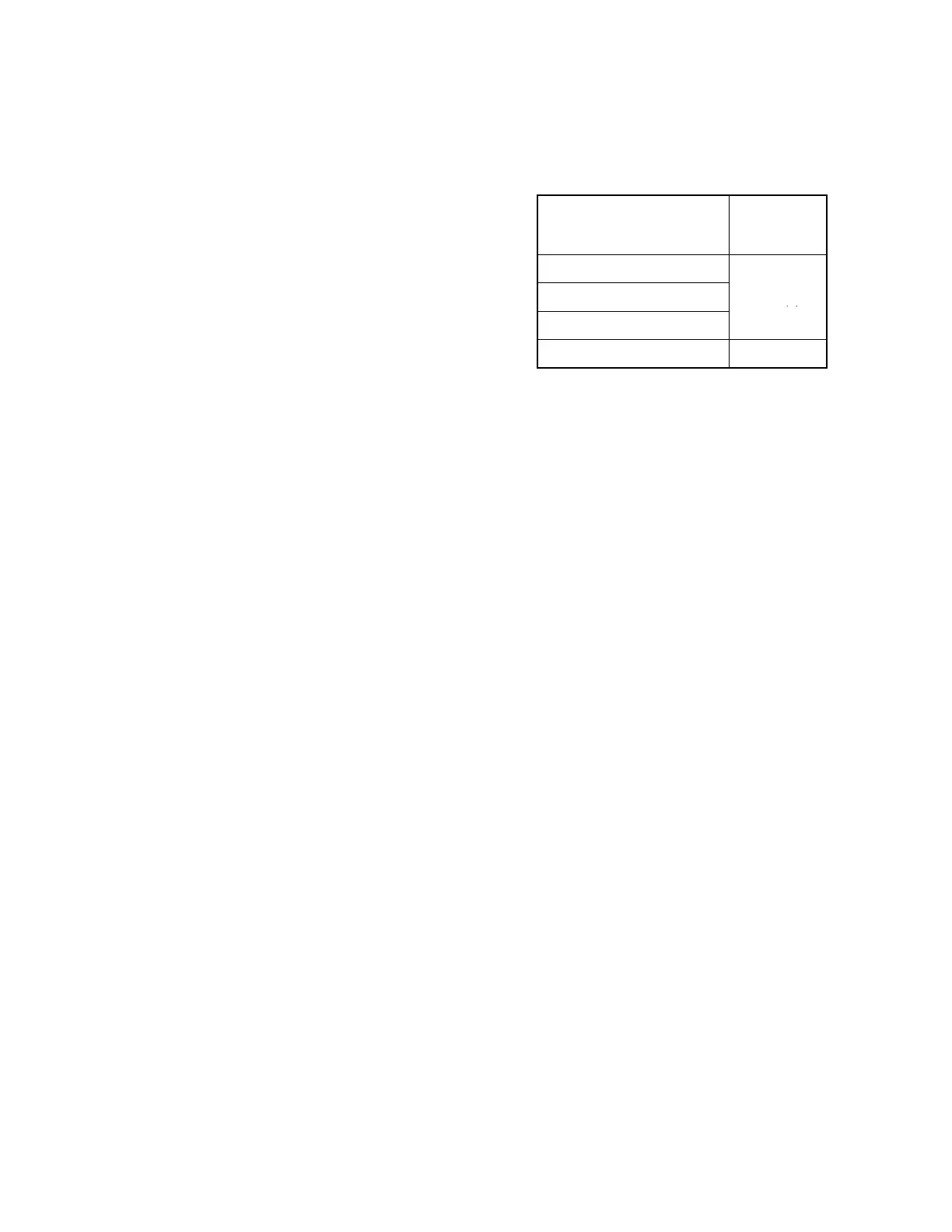

See Figure 5-7 for fuel pump lift capabilities. Consult

current generator set specification sheets for generator

set fuel consumption rates.

Model

Fuel Pump

Lift

m (ft.)

5/7.3E and 4/6EF

5/7.3ECD and 4/6EFCD

0.9 (3)

10/13/15EG and 13/15EGZ

15/20C and 12.5/16CF 1.2 (4)

Figure 5-7 Fuel Pump Lift Capabilities (Max.)

Loading...

Loading...