TP-6195 1/04 27Section 6 Installation

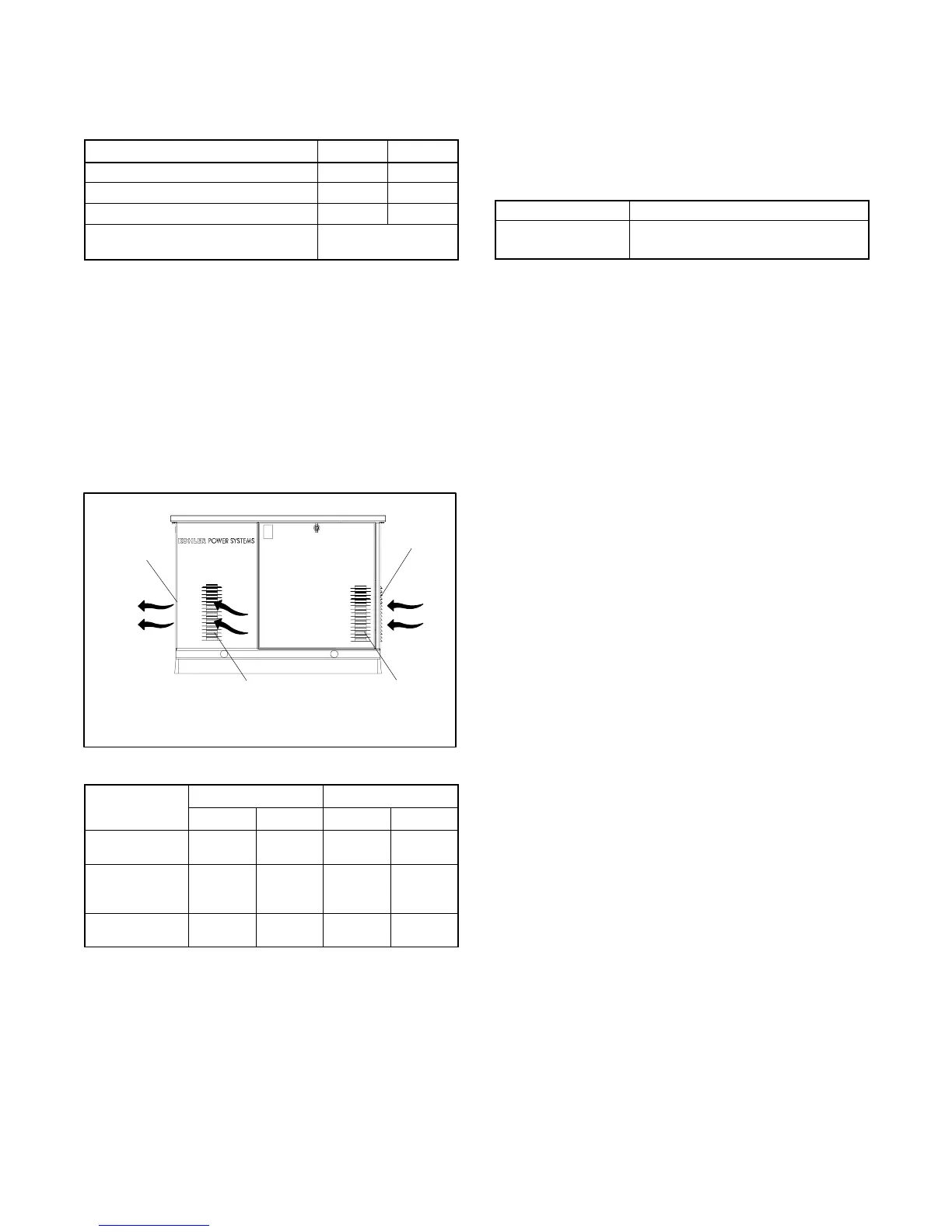

Figure 6-2 gives the exhaust flow and temperature at

rated load. Mount the generator set so that the hot

exhaust does not blow on plants or other combustible

materials.

Exhaust System 60 Hz 50 Hz

Exhaust flow at rated kW, m

3

/min. (cfm)

8.5RES 3.3 (115) 2.7 (96)

12RES 3.8 (135) 3.2 (113)

Exhaust temperature at rated kW, dry

exhaust, _C(_F)

816 (1500)

Figure 6-2 Exhaust Flow and Temperature

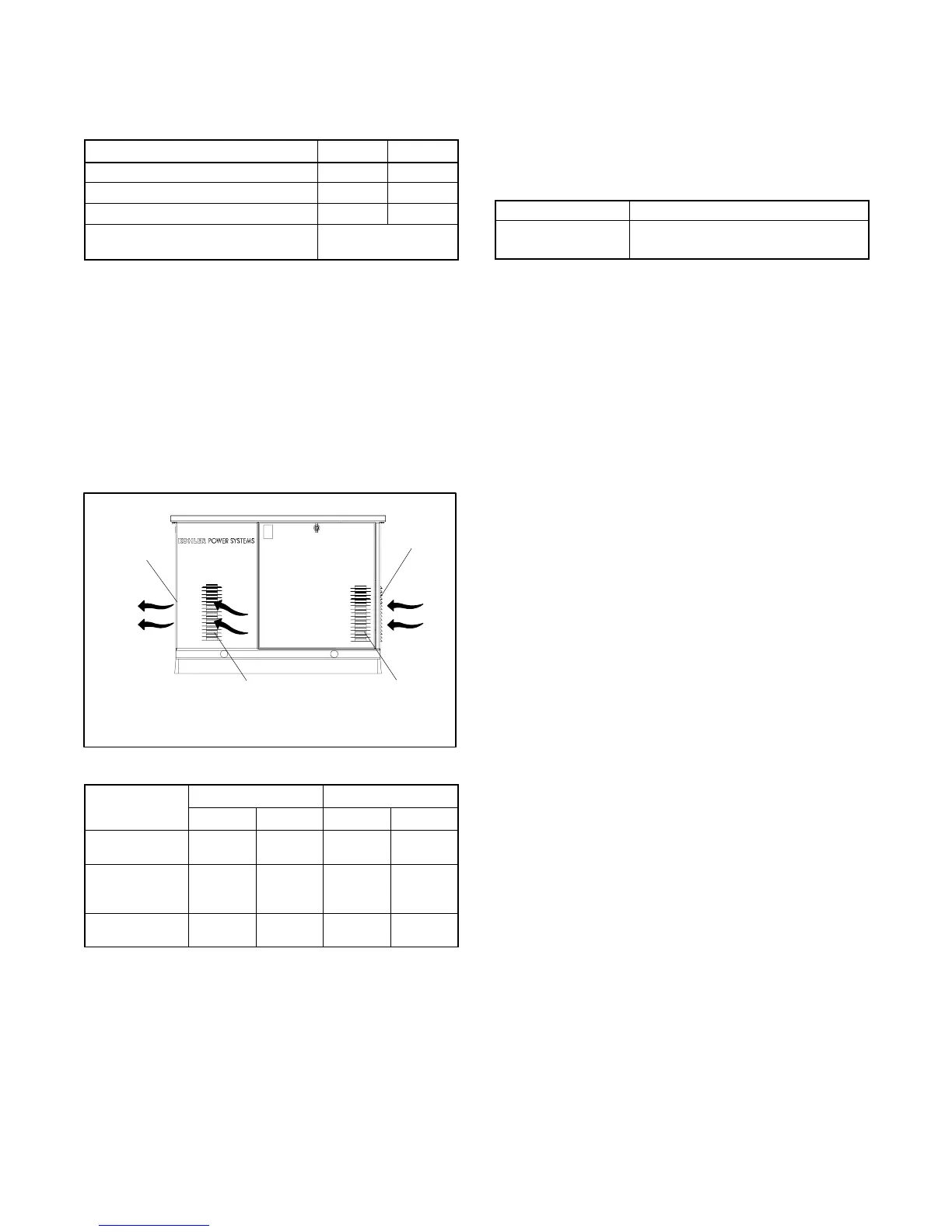

6.6 Air Requirements

The generator set requires correct air flow for cooling

and combustion. The inlet and outlet openings in the

sound enclosure provide the cooling and combustion

air. Figure 6-3 shows the locations of the cooling air

intake and exhaust vents. Inspect the air inlet and outlet

openings inside and outside the housing to ensure that

the air flow is not blocked.

tp6195

2

1. Exhaust outlet

2. Alternator air intake (both sides)

3. Engine air intake

3

1

3

Figure 6-3 Cooling Air Intake and Exhaust

8.5RES 12RES

Requirements

60 Hz 50 Hz 60 Hz 50 Hz

Cooling air,

m

3

/min. (cfm)

26.9 (950) 22.4 (790) 26.9 (950) 22.4 (790)

Total inlet air

requirement,

m

3

/min. (cfm)

27.8 (980) 23.2 (820) 28.0 (990) 23.4 (825)

Combustion air,

m

3

/min. (cfm)

0.94 (33.4) 0.8 (28.0) 1.1 (39.2) 0.9 (32.6)

Figure 6-4 Cooling Air Requirements

6.7 Power Supply

Utility power must be supplied to the generator set

location. Provide a 110- or 120-volt outlet connected to

the utility power supply for the battery charger

(standard) and carburetor heater (optional). Figure 6-5

lists the battery charger power requirements.

Input Requirement

Rated AC voltage 90--135 VAC, 50/60 Hz

Current draw 1.6 amp at full output

Figure 6-5 Battery Charger Power Requirements

6.8 Fuel System

The generator set operates using natural gas or LP

vapor fuel. The multi-fuel system allows conversion

from natural gas to LP vapor (or vice-versa) in the field

while maintaining emissions-standard compliance. A

trained technician or authorized distributor/dealer can

convert the fuel system. Generator sets with multi-fuel

systems are CARB- and EPA-certified for both natural

gas and LP vapor fuels.

6.8.1 Fuel Supply

Comply with local, state, and federal codes regarding

the correct s torage of fuel. Because of variable climates

and geographical considerations, c ontact an authorized

service distributor/dealer for fuel system planning and

installation.

Figure 6-1 shows the location of the fuel inlet

connection. Bring the fuel supply lines through the rear

access opening. Use flexible sections to prevent fuel

line breakage caused by vibration. Remove the housing

end panel and hold the fuel solenoid valve with a wrench

when tightening the fuel connections. Protect all fuel

lines from machinery or equipment contact, adverse

weather conditions, and environmental damage.

Verify that the output pressure from the primary gas

utility (or LP tank) pressure regulator is 1.7--2.7 kPa

(7--11 in. water column) and that the utility gas meter

flow rate is sufficient to supply the generator set plus all

other gas-consuming appliances. Figure 6-8 shows the

flow rate required for the generator set. Figure 6-6 lists

Loading...

Loading...