Electrical System

76 24 690 06 Rev. PKohlerEngines.com

15/20/25 Amp Battery Charging Systems

NOTE: Always zero digital volt-ohm meter (DVOM) on each scale before testing to ensure accurate readings. Voltage

test should be made with engine running at specifi c test condition noted. Battery should be checked for state

of charge (non-operating voltage 12.5 VDC or lower, battery should be charged or replaced).

When problems occur in keeping a battery fully charged or a battery charges at a high rate, battery or charging

system may be cause of fault. Before performing any testing, battery must be fully charged.

To test charging system:

1. Visually inspect system components and wiring.

Look for damaged or loose wire connections,

including battery cables.

2. Set DVOM to DC volts, place one lead of tester on

rectifi er-regulator body and other lead to battery

negative (-) terminal. Run engine and observe volt

reading on meter. If voltage is 0.5 VDC or less

continue with testing. If voltage is higher than 0.5

VDC, inspect and repair wiring/connections as

needed (insuffi cient ground).

3. Perform these output tests for charging system using

DVOM set to DC volts.

a. With engine off and key switch in OFF position,

measure voltage at battery. If less than 12.4 VDC,

recharge battery and retest. If 12.5 VDC continue

with tests.

b. Run engine at high speed no load (greater than

3000 RPM). After running 1 minute, measure

voltage at battery.

i. If voltage increases to between 13-15 VDC,

the system is working correctly.

ii. If voltage increases to 15.5 VDC or higher,

system is overcharging. Replace rectifi er-

regulator.

iii. If voltage stays at 12.5 VDC or decreases,

charging system is NOT operating, proceed to

step 4.

4. With engine off , unplug rectifi er-regulator connector

and inspect connector terminals within connector

body and rectifi er-regulator terminals for corrosion/

arcing/damage. Repair/replace as needed. If OK,

proceed to next test.

5. Set DVOM to AC volts, place test leads to each

white stator wire. Run engine at 1200 RPM or

greater and monitor voltage.

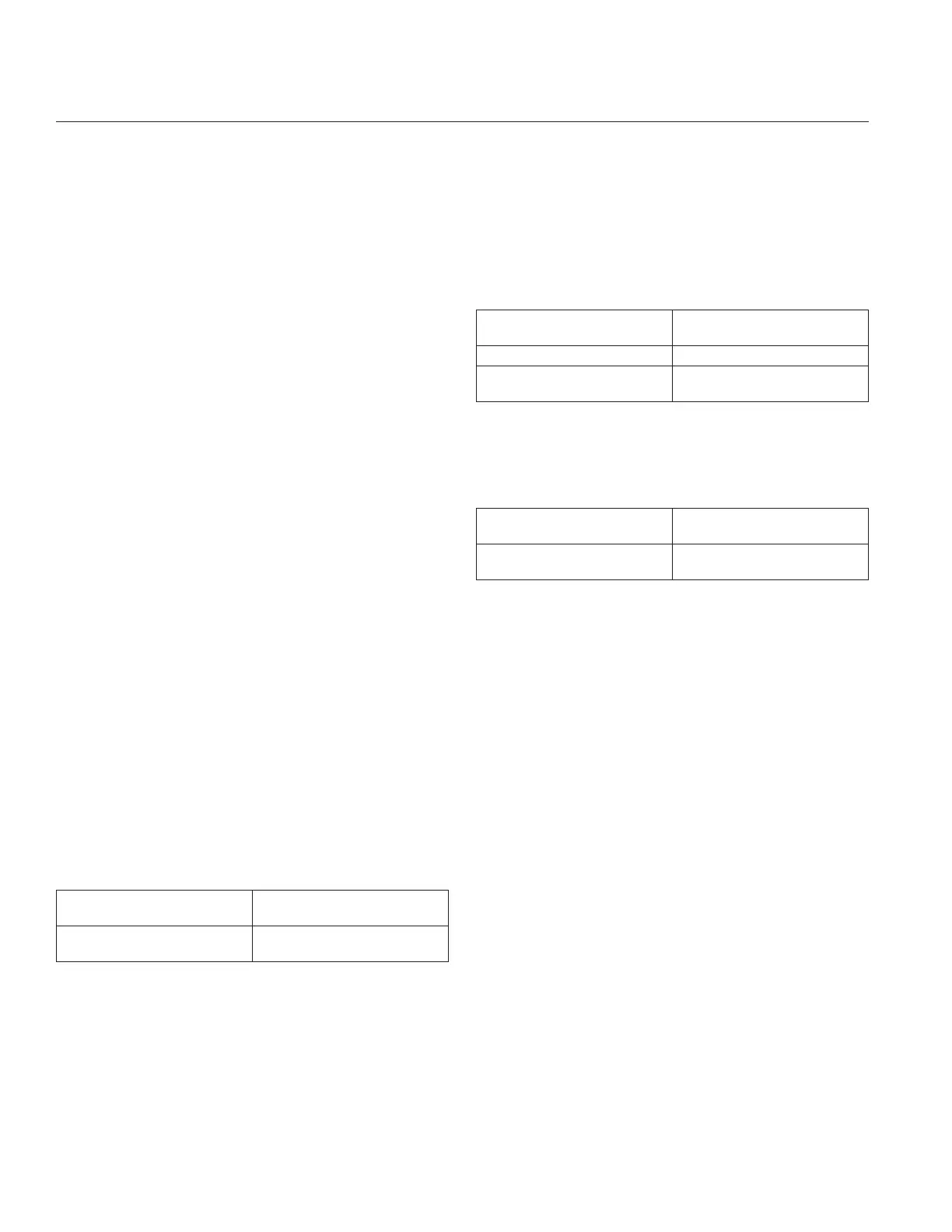

Condition Conclusion

Voltage is 13 volts AC or

more.

Stator is OK.

Voltage is less than 13

volts AC.

Stator is faulty. Continue

with steps 6 and 7.

6. With engine off and stator unplugged from rectifi er-

regulator, check for resistance/continuity between

across stator leads (white wires).

Condition Conclusion

Resistance is 0.1/0.2

ohms.

Stator coil is OK.

Resistance is 0 ohms. Stator is shorted; replace.

Resistance is infi nity

ohms/no continuity.

Stator is open; replace.

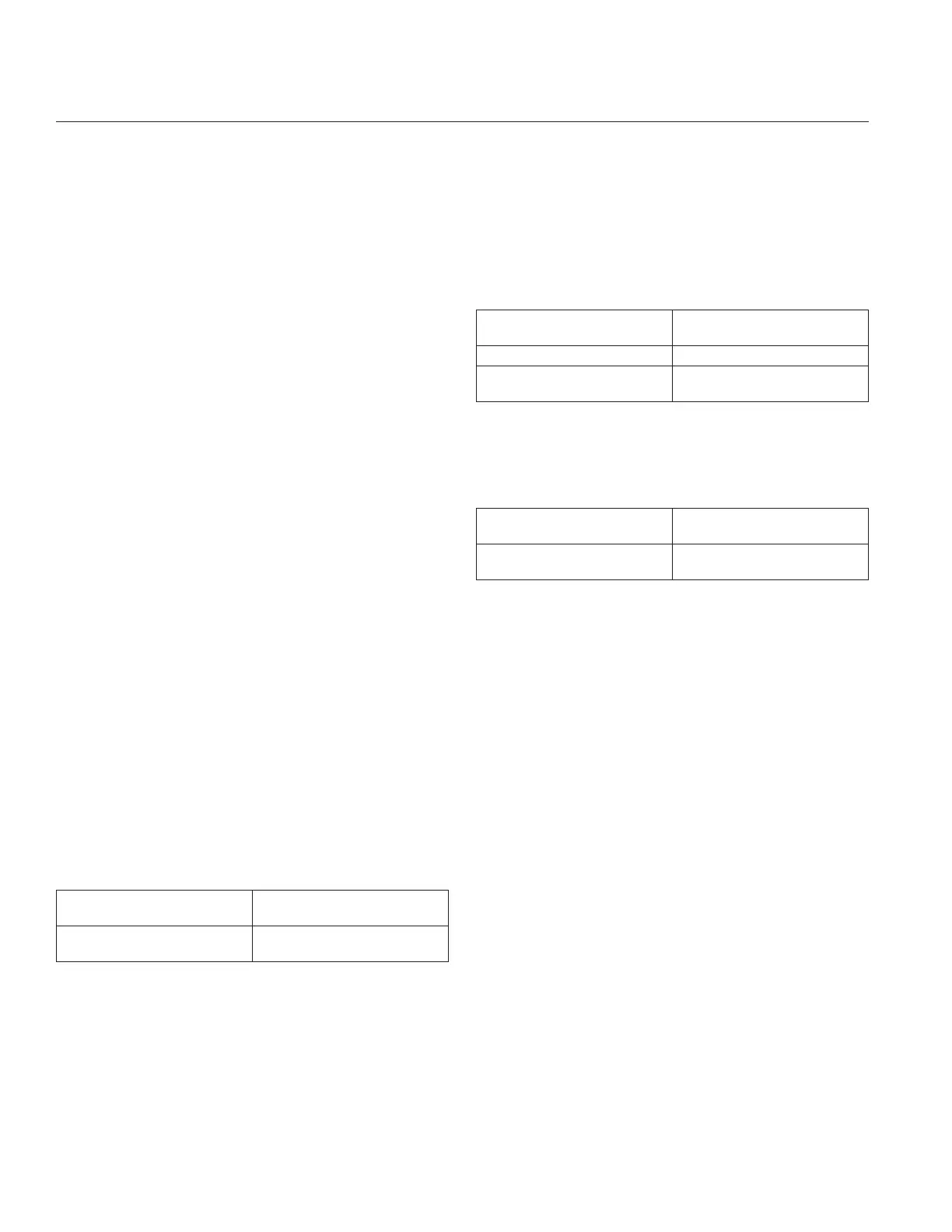

7. With engine off and stator unplugged from rectifi er-

regulator, check for resistance/continuity from stator

leads (white wires) to ground.

Condition Conclusion

Resistance is infi nity ohms

(no continuity).

Stator is OK (not shorted

to ground).

Resistance (or continuity)

measured.

Stator leads are shorted to

ground; replace.

8. If stator tests good (steps 4-7), but system was

identifi ed in step 3 as not working, failure is likely

with rectifi er-regulator. Replace rectifi er-regulator,

retest system to confi rm repairs (step 3).

Loading...

Loading...