74

Disassembly/Inspection and Service

KohlerEngines.com 24 690 06 Rev. J

4. After resizing, check bore for roundness, taper, and

size. Use an inside micrometer, telescoping gauge,

or bore gauge to take measurements. These

measurements should be taken at 3 locations in

cylinder–at top, middle, and bottom. There are 2

measurements that should be taken (perpendicular

to each other) at all 3 locations.

Clean Cylinder Bore After Honing

Proper cleaning of cylinder walls following boring and/

or honing is very critical to a successful overhaul.

Machining grit left in cylinder bore can destroy an engine

in less than one hour of operation after a rebuild.

Final cleaning operation should always be a thorough

scrubbing with a brush and hot, soapy water. Use a

strong detergent capable of breaking down machining

oil while maintaining a good level of suds. If suds break

down during cleaning, discard dirty water and start again

with more hot water and detergent. Following scrubbing,

rinse cylinder with very hot, clear water, dry it completely,

and apply a light coating of engine oil to prevent rusting.

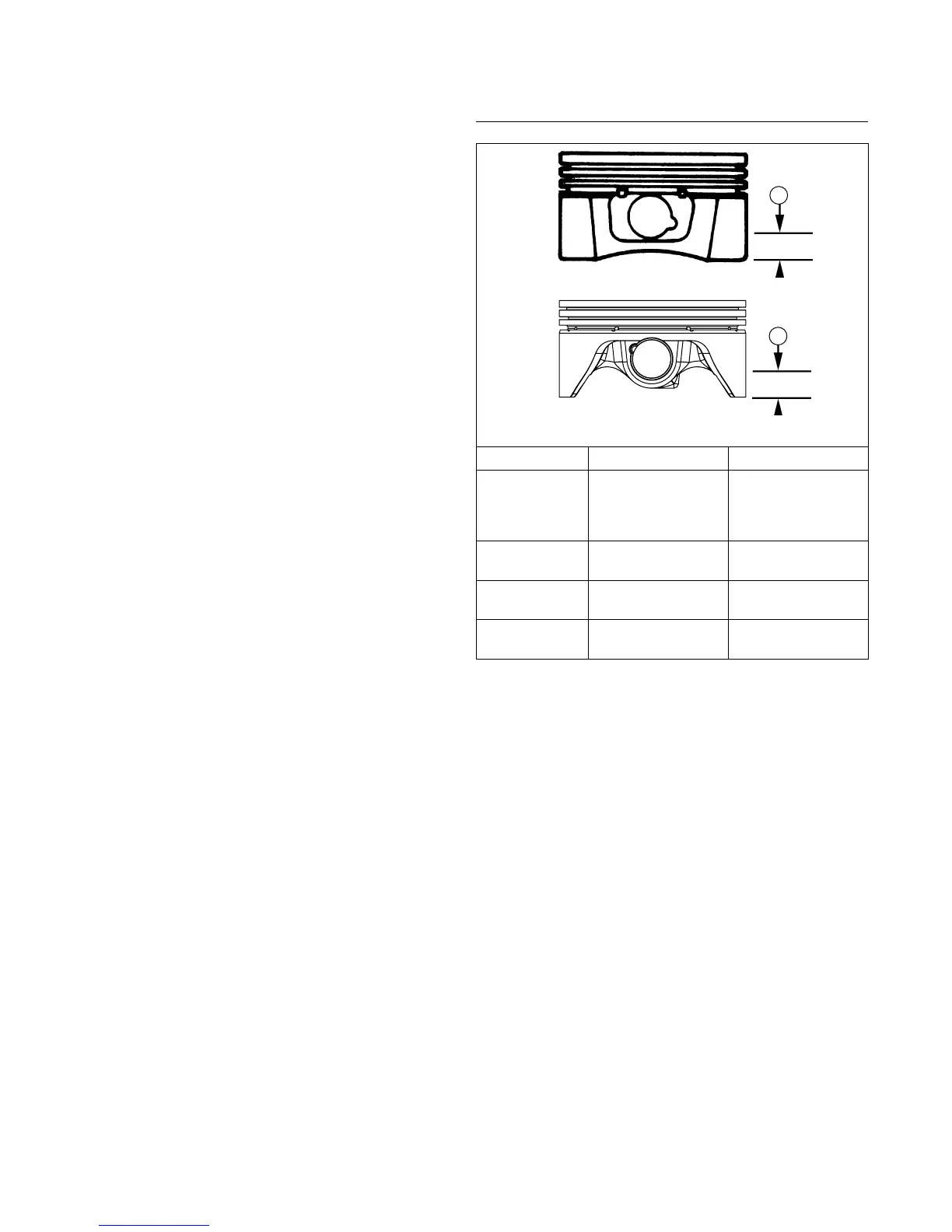

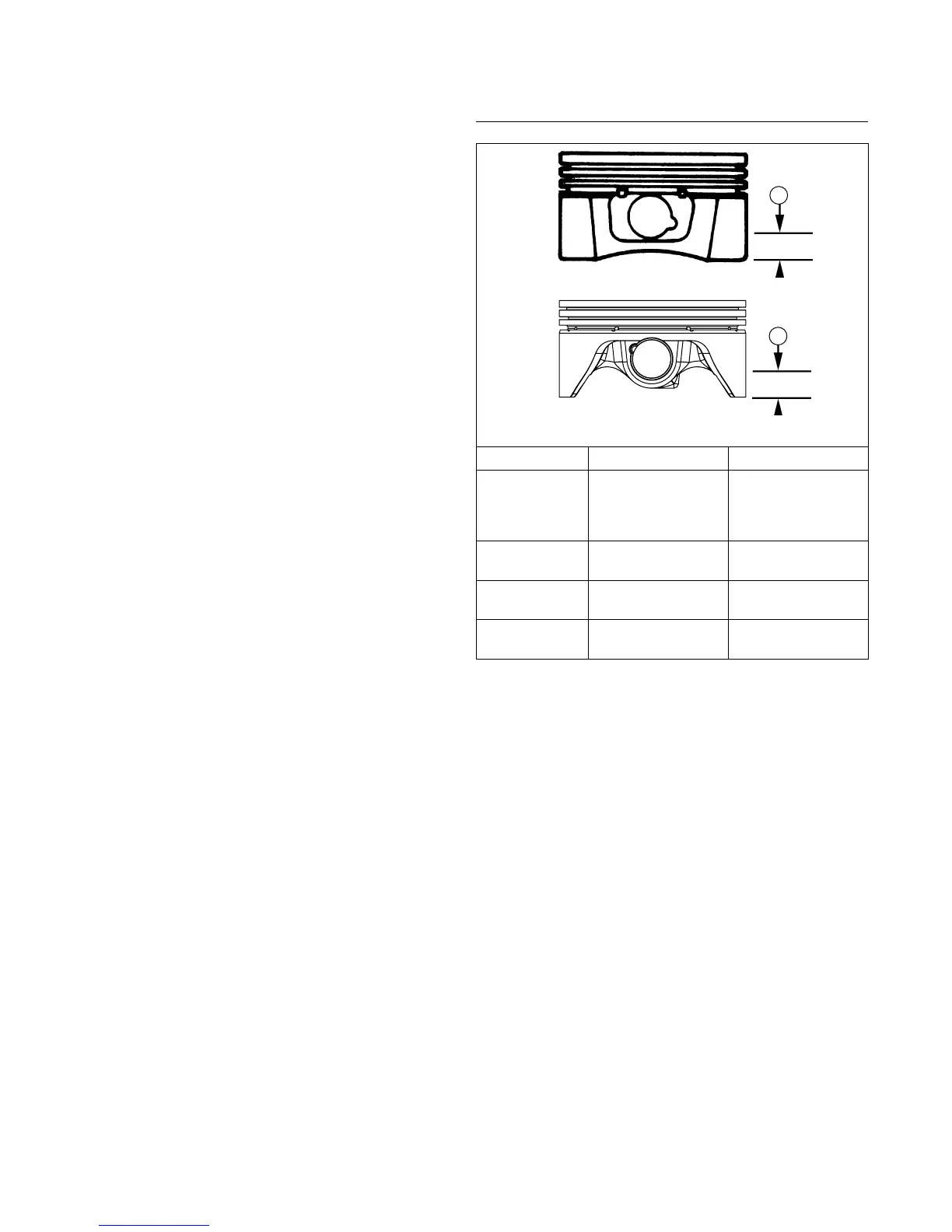

Measuring Piston-to-Bore Clearance

Piston Detail

A

B

Style A

Style B

Model Dimension A Dimension B

CH18/CH20/

CH22/

CH620/CH621/

CH640/CH641

6 mm (0.2362 in.) --

CH22/CH23/

CH670/CH680

6 mm (0.2362 in.) 13 mm (0.5118 in.)

CH620 674cc

CH640 674cc

-- 13 mm (0.5118 in.)

CH25/CH730/

CH740/CH750

6 mm (0.2362 in.) 6 mm (0.2362 in.)

NOTE: Do not use a feeler gauge to measure piston-to-

bore clearance–it will yield inaccurate

measurements. Always use a micrometer.

Before installing piston into cylinder bore, it is

necessary clearance be accurately checked. This step

is often overlooked, and if clearances are not within

specications, engine failure will usually result.

Use following procedure to accurately measure piston-

to-bore clearance:

1. Use a micrometer and measure diameter of piston

above bottom of piston skirt and perpendicular to

piston pin.

2. Use an inside micrometer, telescoping gauge, or

bore gauge and measure cylinder bore. Take

measurement approximately 63.5 mm (2.5 in.) below

top of bore and perpendicular to piston pin.

3. Piston-to-bore clearance is difference between bore

diameter and piston diameter (step 2 minus step 1).

Loading...

Loading...