Install Fuel Pump

WARNING

Explosive Fuel can cause res and severe

burns.

Do not ll fuel tank while engine is hot or

running.

Gasoline is extremely ammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or ames. Spilled fuel could ignite if

it comes in contact with hot parts or sparks from

ignition. Never use gasoline as a cleaning agent.

NOTE: Pulse style fuel pumps may be made of metal or

plastic. If a new fuel pump is being installed,

make sure orientation of new pump is consistent

with removed pump. Internal damage may occur

if installed incorrectly.

1. Install pulse style fuel pump and lines as an

assembly. Connect pulse line to crankcase vacuum

tting or valve cover, whichever source is used.

2. Install fuel pump using screws. Torque screws to

2.3 N·m (20 in. lb.).

Install Carburetor

WARNING

Explosive Fuel can cause res and severe

burns.

Do not ll fuel tank while engine is hot or

running.

Gasoline is extremely ammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or ames. Spilled fuel could ignite if

it comes in contact with hot parts or sparks from

ignition. Never use gasoline as a cleaning agent.

One-Barrel Carburetor Models

1. Install a new carburetor gasket. Make sure all holes

align and are open.

2. Install carburetor, throttle linkage and governor lever

as an assembly. If a plastic intake manifold is used

and carburetor is equipped with a fuel solenoid,

attach ground lead to carburetor mounting screw.

3. Torque carburetor mounting screws to

6.2-7.3 N·m (55-65 in. lb.).

Two-Barrel Carburetor Models

1. Use a new carburetor gasket. Make sure all holes

align and are open.

2. Apply Loctite

®

242

®

to shorter (inner) set of threads

of any removed studs.

3. Assemble carburetor gasket and carburetor to intake

manifold, and start any removed studs. Use two

ange nuts locked ange to ange and tighten each

stud until bottomed/tight.

4. Connect ground lead and fuel solenoid lead as

equipped.

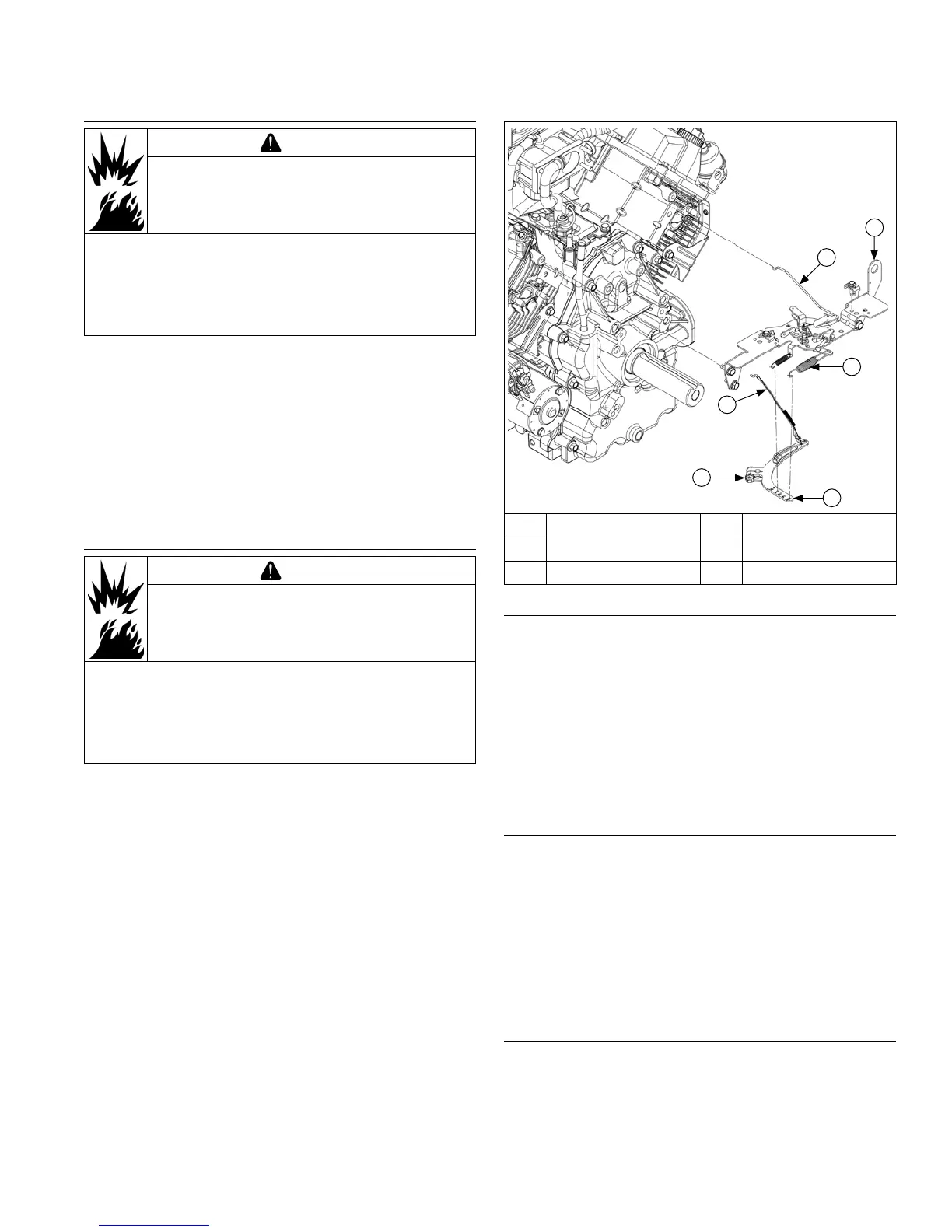

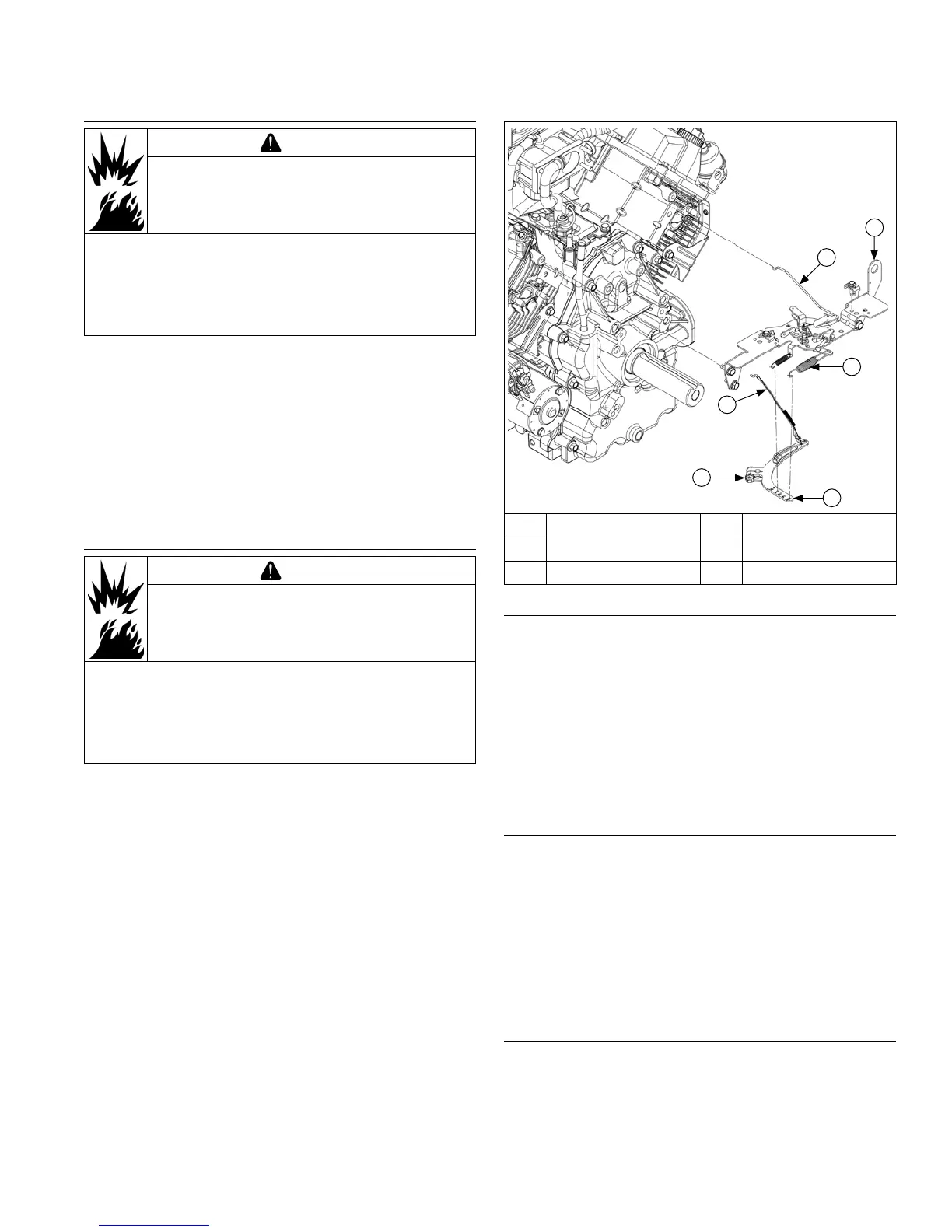

Control Bracket Components

E

F

D

C

B

A

A Choke Linkage B Control Bracket

C Spring D Governor Lever

E Nut F Throttle Linkage

Install External Governor Controls

1. Install governor lever onto governor cross shaft.

2. Make sure throttle linkage is connected to governor

lever and throttle lever on carburetor.

3. Move governor lever toward carburetor as far as it

will go (wide-open throttle) and hold in position.

4. Insert a nail into hole on cross shaft and rotate shaft

counterclockwise as far as it will turn, then torque

nut to 6.8 N·m (60 in. lb.).

5. Reconnect lead wire to fuel shut-off solenoid if

equipped.

Install Throttle & Choke Controls

1. Connect choke linkage to carburetor and choke

actuator lever.

2. Mount main control bracket, and air cleaner support

bracket (if used) to cylinder heads using four screws.

Torque screws to 10.7 N·m (95 in. lb.) into new

holes, or 7.3 N·m (65 in. lb.) into used holes.

3. Connect governor spring from main control bracket

to appropriate hole in governor lever as indicated in

applicable chart. Note that hole positions are

counted from pivot point of governor lever.

Install Oil Sentry

™

(if equipped)

1. Apply pipe sealant with Teon

®

(Loctite

®

PST

®

592™

or equivalent) to threads of Oil Sentry

™

switch and

install it into breather cover. Torque to 4.5 N·m

(40 in. lb.).

2. Connect wire lead (green) to Oil Sentry

™

terminal.

Reassembly

8524 690 06 Rev. J KohlerEngines.com

Loading...

Loading...