8.25

Section 8

Electrical System and Components

8

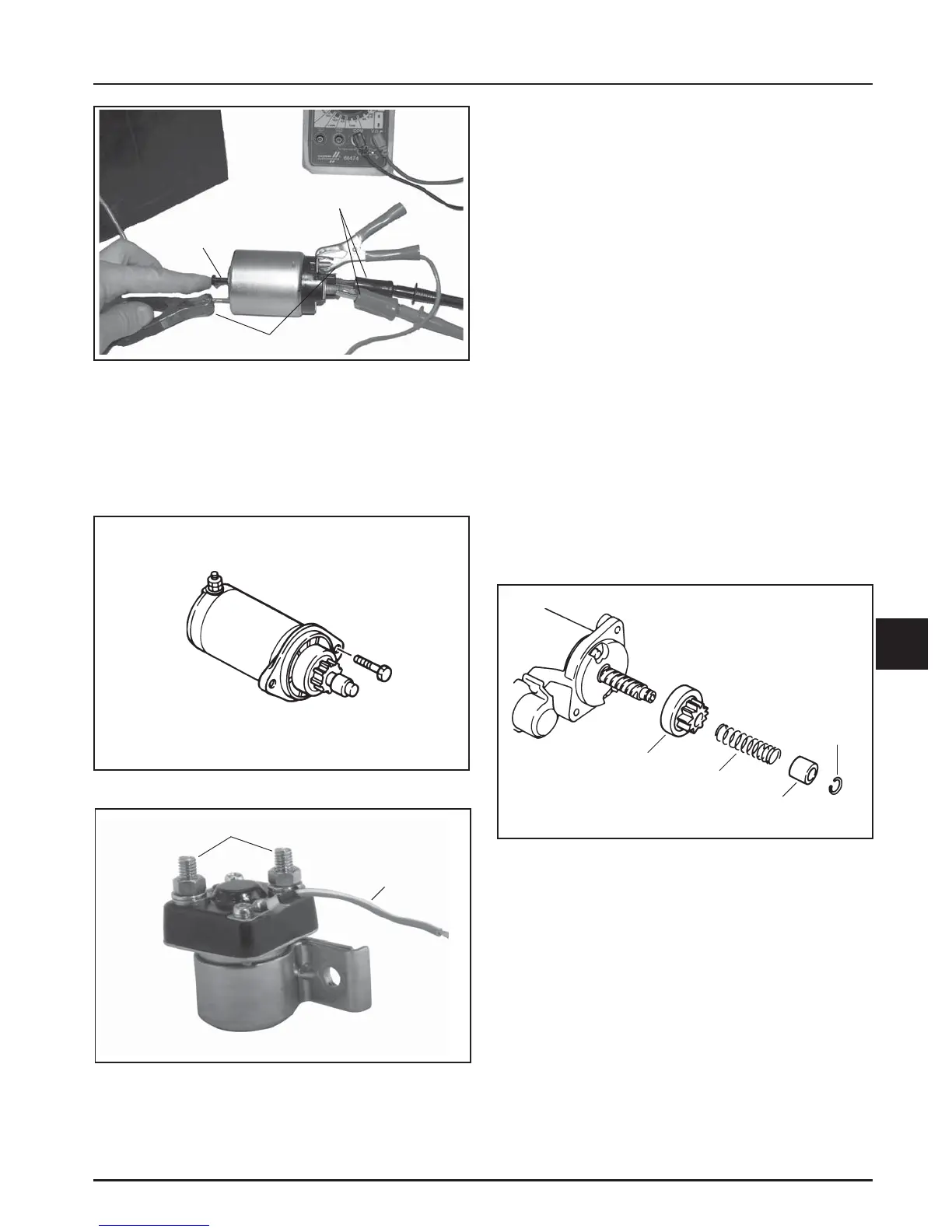

Plunger

Pushed “In”

VOM Meter

Leads

12 volt Test Leads

Figure 8-31. Testing Hold-In Coil/Solenoid Contact

Continuity.

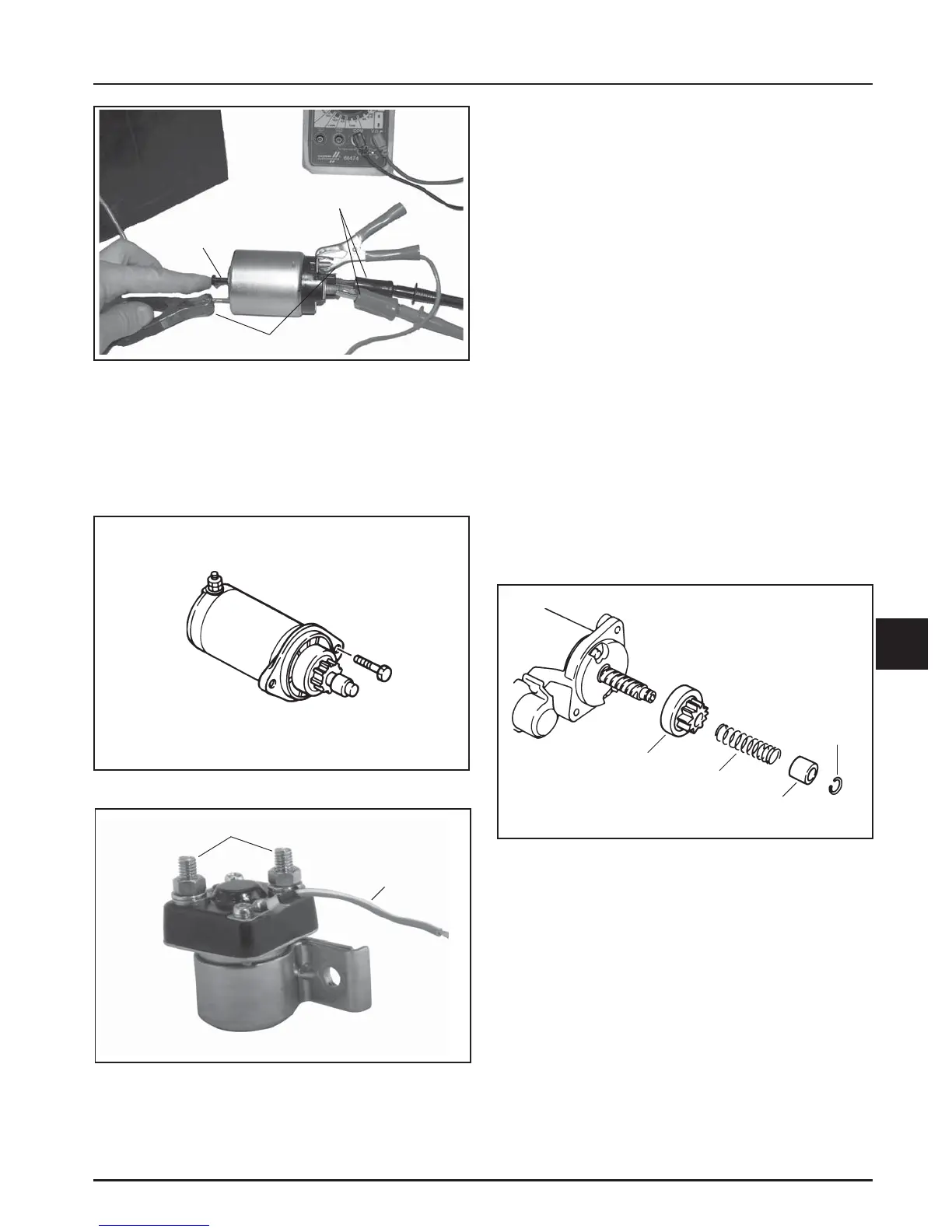

Inertia Drive Electric Starters

This subsection covers the operation, troubleshooting,

and repair of the inertia drive, permanent magnet

electric starter.

Figure 8-32. Inertia Drive Starter.

Operation

When power is applied to the starter, the armature

rotates. As the armature rotates, the drive pinion

moves out on the splined drive shaft and into mesh

with the flywheel ring gear. When the pinion reaches

the end of the drive shaft, it rotates the flywheel and

cranks the engine.

When the engine starts, the flywheel rotates faster

than the starter armature and drive pinion. This moves

the drive pinion out of mesh with the ring gear and

into the retracted position. When power is removed

from the starter, the armature stops rotating and the

drive pinion is held in the retracted position by the

anti-drift spring.

Starter Drive Service

Every 300 hours of operation (or annually, whichever

occurs first), clean and lubricate the splines on the

starter drive shaft. If the drive pinion is worn, or has

chipped or broken teeth, it must be replaced.

It is not necessary to completely disassemble the

starter to service the drive components. Service the

drive as follows:

Figure 8-34. Drive Components.

1. Remove the starter from the engine.

2. Push back the spring holder (collar) to expose the

retaining ring on the armature shaft, which

secures the drive components. Remove the

retaining ring using either of the Kohler retaining

ring removal tools.

Drive Pinion

Spring

Retaining

Ring

Spring

Holder (Collar)

Post Terminals

Red/White

Lead

Figure 8-33. Solenoid Details.

Loading...

Loading...