93

Reassembly

62 690 13 Rev. A KohlerEngines.com

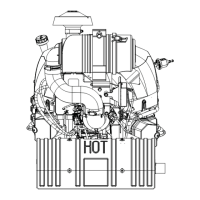

Install Rectifi er-Regulator

B

A

C

D

A Ground Lead B Ground Lead Screw

C Screw D Rectifi er-Regulator

1. If purple wire was removed, verify locking tang is

raised on terminal and push wire terminal into plug

prior to connecting to rectifi er-regulator.

2. Position rectifi er-regulator onto mounting posts and

secure with screws. Torque mounting screws to

2.5 N·m (22 in. lb.).

3. Engine has ground lead that secures in ground lug

fastener hole. Attach ground lead to rectifi er-

regulator and torque to 5.6 N·m (50 in. lb.) into new

holes, or 4.0 N·m (35 in. lb.) into used holes.

4. Connect plug to rectifi er-regulator.

Install Flywheel

CAUTION

Damaging Crankshaft and Flywheel Can

cause personal injury.

Using improper procedures can lead to broken

fragments. Broken fragments could be thrown from

engine. Always observe and use precautions and

procedures when installing fl ywheel.

NOTE: Before installing fl ywheel make sure crankshaft

taper and fl ywheel hub are clean, dry, and

completely free of any lubricants. Presence of

lubricants can cause fl ywheel to be over

stressed and damaged when screw is torqued to

specifi cations.

NOTE: Make sure fl ywheel key is installed properly in

keyway. Flywheel can become cracked or

damaged if key is not properly installed.

1. Install woodruff key into crankshaft keyway. Make

sure key is properly seated and parallel with shaft

taper.

2. Install fl ywheel onto crankshaft, being careful not to

shift woodruff key.

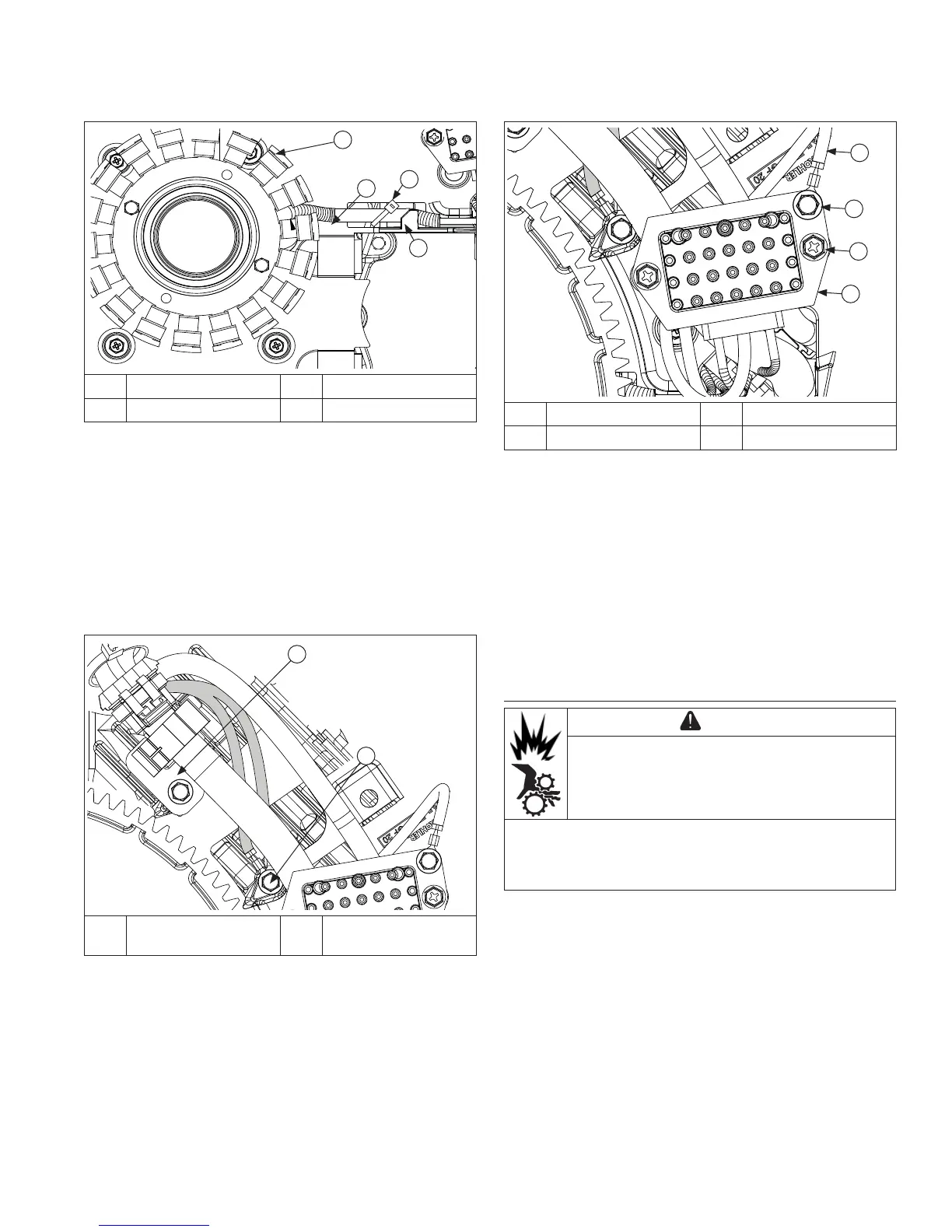

Install Stator

B

A

C

D

A Stator B Stator Leads

C Tie Strap D Molded Clips

1. Apply pipe sealant with Tefl on

®

(Loctite

®

PST

®

592™

Thread Sealant or equivalent) to stator mounting

holes.

2. Position stator, aligning mounting holes so leads are

at 3 o'clock position and toward rectifi er-regulator

mount on cylinder 1 side.

3. Install and torque screws to 9.3 N·m (82 in. lb.).

4. Route stator wires under molded clips and install

new tie strap.

Install Wiring Harness

A

B

A

Wire Harness

Clamp

B Ground Eyelets

1. Install wire harness under molded clips in backing

shroud assembly.

2. Install wire harness clamp and wire harness ground

eyelets. Torque M6 screws to 2.5 N·m (22 in. lb.) into

new holes, or 2.0 N·m (18 in. lb.) into used holes.

Loading...

Loading...