7 — DIAGNOSTICS AND TROUBLESHOOTING

Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022 Return to TOC

pg. 212

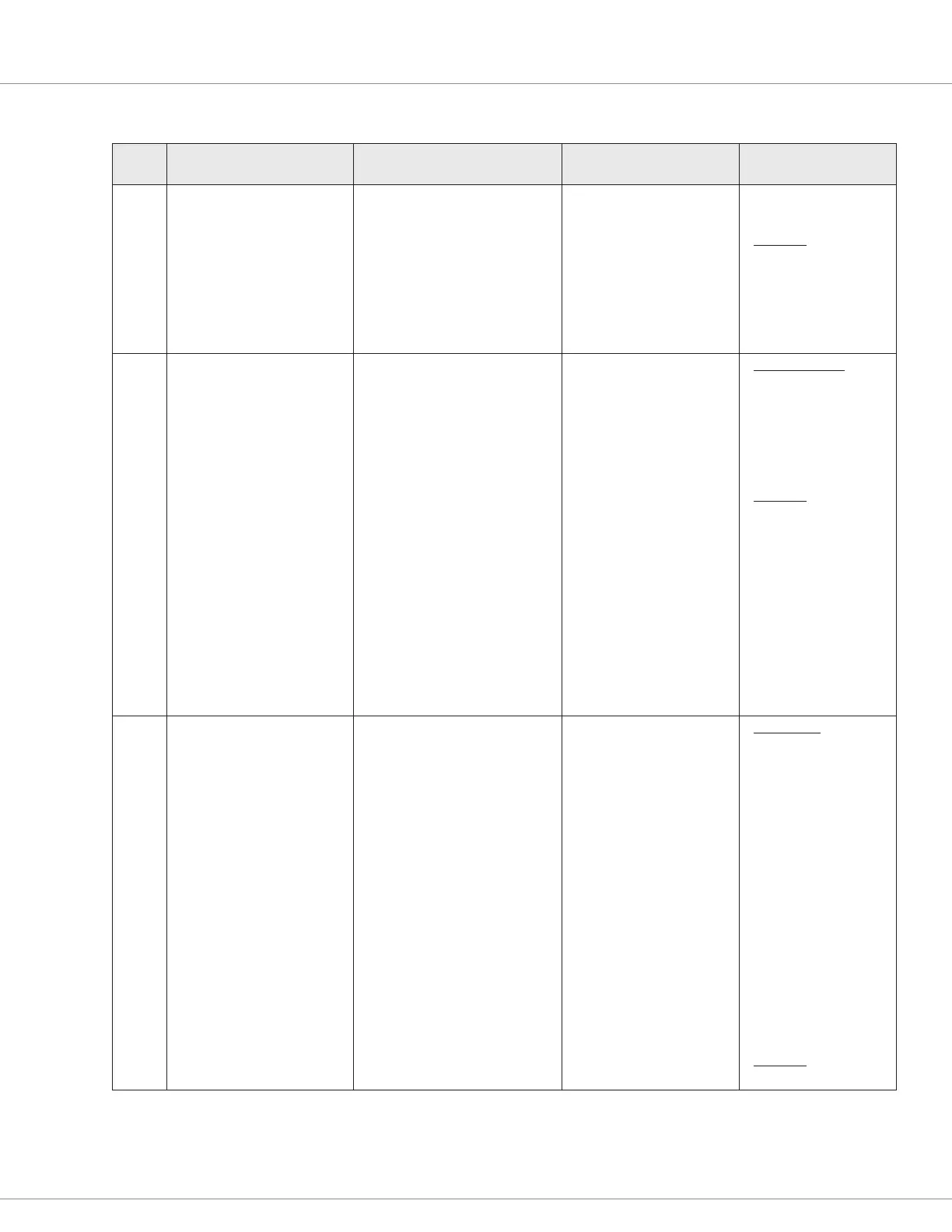

FLASH

CODE

FAULT NAME

(Curtis Integrated Toolkit™)

POSSIBLE CAUSES SET/CLEAR CONDITIONS FAULT ACTIONS

1-9

0x19

Speed Limit Supervision

Speed_Limit_Supervision

0x2133

Fault Type(s): 1

1. Motor speed detected that exceeds

the limit set by the Max Speed

Supervision parameter.

2. Misadjusted Max Speed

Supervision parameters.

3. See: Programmer » Application

Setup » Max Speed

Supervision menu.

Set: Motor rpm has exceeded

the Max Speed Limit setting

for the Max Speed Time Limit

setting’s duration.

Clear: Reset Controller.

ShutdownInterlock

ShutdownEMBrake

Dual Drive

This Motor:

ShutdownInterlock

ShutdownEMBrake

Other Motor:

ShutdownInterlock

ShutdownEMBrake

1-10

0x1A

Motor Not Stopped

Motor_Not_Stopped

0x2134

Fault Type(s):

1 = The motor moved more

revolutions than the

parameter, Motor_Not_

Stopped_Position_Error

setting.

2 = The motor moved faster

than the parameter, Motor_

Not_Stopped_Speed_Error

(RPM) for 160 ms.

3 = The three-phase drive

has applied an electrical

frequency greater than the

Motor_Not_Stopped_Max_

Frequency parameter, and

applied an RMS current

greater than the Motor_

Not_Stopped_Max_Current

parameter for 64 ms.

1. Misadjusted Motor Not

Stopped parameters.

2. See: Programmer » Application

Setup » Motor Not Stopped menu.

3. Internal Controller fault or conict

allowing the motor to rotate when

in the stopped state.

Set: Motor Not Stopped is a

safety function implemented in

the Primary microprocessor on

a category 2 architecture per

ISO 13849. The purpose of this

function is to detect hazardous

movement when the AC motor

is stopped and expected to

stay stopped (i.e., no throttle

command). There are three

main checks done when

the motor is in the stopped

state, each of which can be

independently enabled and

each of which has a unique

fault type.

Clear: Reset Controller.

ShutdownVehicle:

ShutdownMotor

ShutdownMainContactor

ShutdownEMBrake

ShutdownThrottle

FullBrake

ShutdownPump

Dual Drive

This Motor:

ShutdownVehicle

Other Motor:

ShutdownVehicle

1-11

0x1B

Critical OS General

Critical_OS_General

0x2109

Fault Type(s):

(<100) Internal Fault. Contact

Curtis support.

(>100) An ill-formed or

corrupted application

package was loaded

into controller.

1. (<100) Internal Fault.

2. (>100) CIT version is too old to fully

support the FOS version.

Set: Program execution within

the controller encountered a

serious problem and could

not recover.

Clear:

(<100) Internal Fault.

(>100) Update CIT version,

re-package the project,

and re-ash the

application package.

ShutdownAll:

ShutdownMotor

ShutdownMainContactor

ShutdownEMBrake

ShutdownThrottle

ShutdownInterlock

ShutdownDriver1

ShutdownDriver2

ShutdownDriver3

ShutdownDriver4

ShutdownDriver5

ShutdownDriver6

ShutdownDriver7

ShutdownPD

FullBrake

ShutdownPump

ShutdownCoilSupply

ShutdownVehicle

ShutdownLower

ShutdownLift

Dual Drive

Same, both motors

Table 24 Fault Code Troubleshooting Chart, cont’d

Loading...

Loading...