•

••

•

cooling system service

Check

ai

r

intake

sc

ree

n before each s

tart-

up and make sure

it

is

clean

and unobstructed.

If

grass

cl ipp

in

gs, leaves,

dirt

etc.

star

t bui ldulg up on

in

ta

ke screen w

hi

le

oper

ating

, s

top

engine and· clear

to

prevent

overheating. Cooling

air

is

drawn

in

to the

bl

ower housing by f

in

s on

th

e fl

ywhe

el and

is

circulated

past

cooling

fins

on block and heads and i s then discharged toward

the

power

tak

e-off

end

of

the engule . Do not operate wi

th

missing co

oling

shrouds as

these

direct

coo

ling

air--removal would

re-

su

lt

in

improper

air

circulat

ion

and

possible

engine

damage

due t o overhe

at

ing. Clean ex

ternal

surfaces

of

your engine occasiona

ll

y as accumulat ion

of

dust , oi l can cont r ibu

te

to

im

pro

per

coo

li

ng.

Ignition system service

Engine

misfire

or

generally

poor

operation

is

often

caused by spark plugs

in

poor co

ndition

or with

incorrect

spark gap se

tting.

Always

c

lean

area

around spark plugs before re

moving

to prevent

dirt

from

getting

into

engine .

Carefull

y note spark plug condi

tion

as

this

is

often

a good

indicator

of

t he

ign

i -

tion

trouble.

Plugs

fail

for

various

reasons. The porcela

in

insula

tor

may

crack or

become

coated

w

ith

oil,

carbon or o

ther

depo

sits.

This can cause the high vol t age igni

tion

impulse to pass from

the

center

electrode

to ground wi

thout

jumpUlg

the

spark gap.

As

an engine o

perate

s,

the

electrodes

are

gradually

burned

or

worn away. In t ime ,

the

gap

becomes

so wide t hat the a

vailable

ignition

voltage

cannot

jump

the gap and

the

engine misses .

Opera

tion

is

also

greatly

a

ffected

by

breaker

point con

dition

and adjustment

of

poi

nt

gap. If

points

are

burned or badly ox

idized,

l i

ttle

or

no

curre

nt

w

ill

pass and as a

result

the engine

may

not

operate

at

all

,

or

if

i t does

run,

it

is

likely

to

miss

particularly

at

full

throt t l e.

SPARK

PLUGS:

Every 100 hours

remove

p

lugs,

check

condition

and

reset

gap or

replace

plug

if

needed.

Good

operating

conditions

are

indicat ed i f plug has

light

coating

of

gray or

tan

deposi

t.

A dead

white,

blistered

coating

could

in

di

cate

overheating. A

black

(carbon) coa

ting

ma

y

indicate

an

"overrich"

fuel

mixture caused by clogged

ai

r

cleaner

or improper carbure

tor

adjustment. Do

not

sandblast,

wi re brush,

scrape or

othe

rwise

service

plug

in

poor condi

tion

--bes

t

resu

lts

are

obtained w

ith

new

plug.

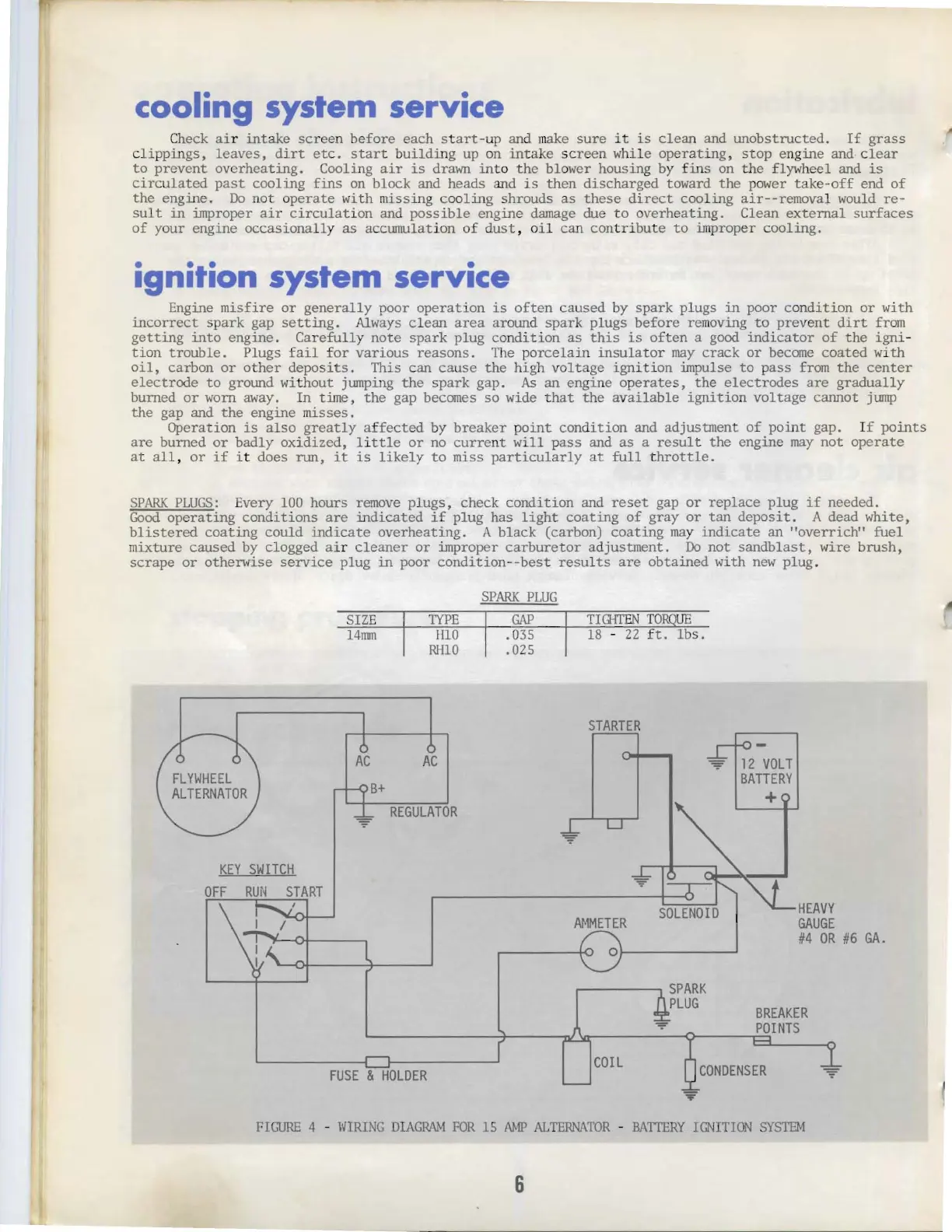

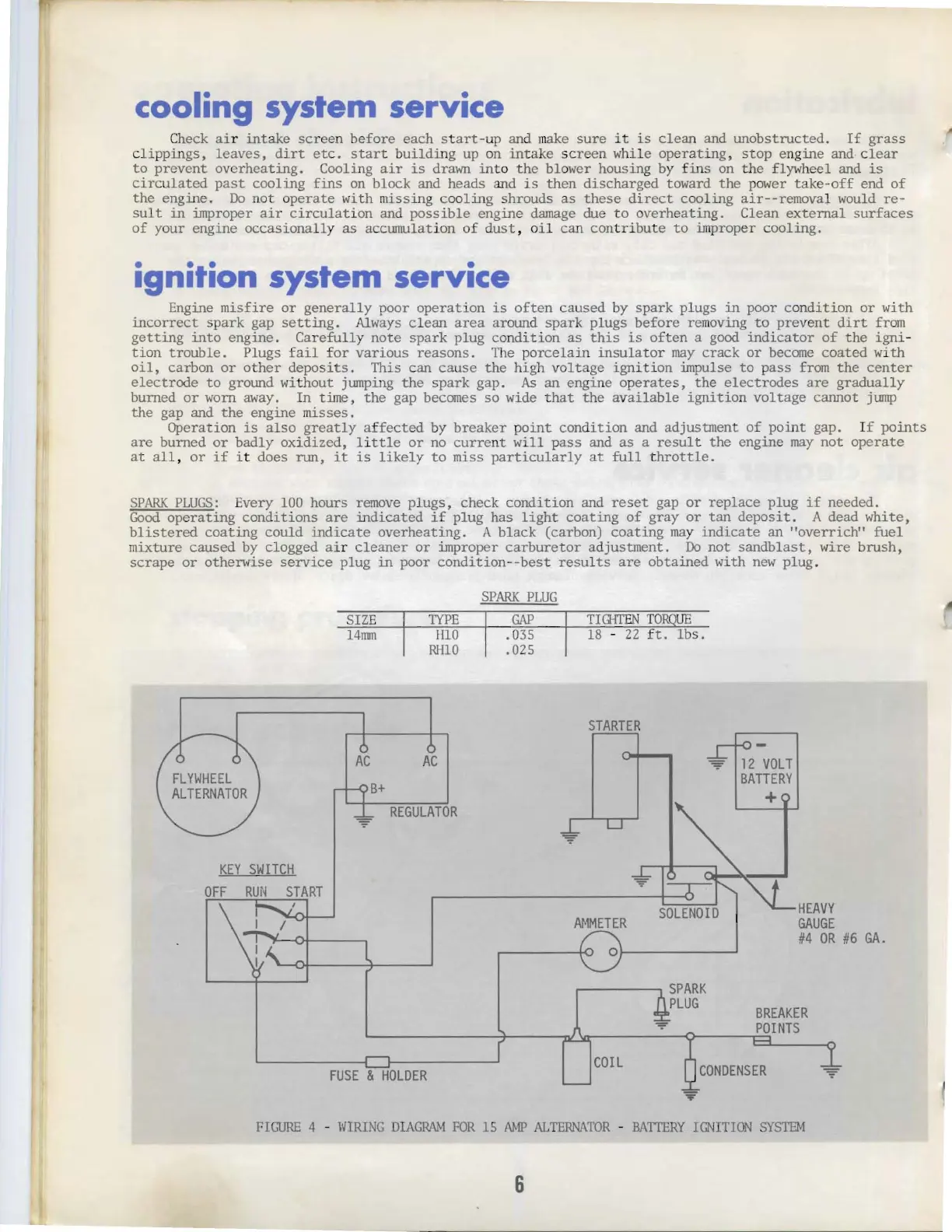

SPARK

PLUG

SIZE

TYPE

GAP

TIQ-ITEN TORQ

UE

14mm

III0

. 035

18 - 22 f t . Ibs .

RHIO

.025

H

EAV

Y

GA

UGE

#4 OR #6

GA.

BRE

AK

ER

P

OI

NTS

-.;;:-

12 VOLT

BATTERY

+

CONDENSER

01---------'

CO

IL

ST

AR

TE

R

Af.'

METER

,..-------,

SP

A

RK

PL

UG

RE

GU

LA

TOR

F

USE

&

HOLDER

FIGURE

4 -

WIRING

DlAG

RAM

FOR

15 AMP

ALTERNATOR

-

BATIERY

IGN

ITI N

SYSTEM

6

Loading...

Loading...