AIR INTAKE

The importance of maintaining an air cleaner in proper condition cannot

be

overemphasized!

Dirt induced through improperly installed, improperly serviced or inadequate elements, wears out

more engines than does long hours of operation.

Even a small amount of dirt will wear out a set of

piston rings in just a few hours. Furthermore, operating with a clogged element causes the fuel mix

-

ture to

be

richer which can lead to formation of harmful sludge deposits in the engine.

Always cover

carburetor or air intake horn when air cleaner is removed for servicing. Do not neglect servicing

air

cleaner at recommended intervals and use only genuine Kohler parts for replacement. Keep other air

intake components such as adapters,

hoses, clamps, etc. secure and in good condition to prevent

entrance of unfiltered air.

Under normal operating conditions, disassemble and service air cleaner components every

50

hours

of operation. Do this more frequently (even daily)

if

extremely dusty or dirty conditions prevail.

attempt to clean dry type elements in any liquid or with compressed air as this will damage

paper filter material. Wipe dirt or dust accumulation from cover including base plate where used.

Replace when dirty with genuine Kohler filter element.

When replacing element use only genuine Kohler part. Carefully handle new element

--

do not use

if

gasket surfaces are bent or twisted.

Not only must the right filter be used but

it

must be properly

installed to prevent unfiltered air from entering the engine. Check the following when installing new

or serviced element.

1.

Back plate

(K482, K532) air horns and adapters must be securely tightened to carburetor.

Replace

bent or cracked back plate when used.

Gaskets between back plate or air horn and carburetor must

be in good condition.

2.

Gasket surfaces of element must be flat against cover (and back plate when used) to seal effectively.

3.

Copper washer (if used) must be positioned between cover and wing nut to seal and prevent unfiltered

air from entering through center hole in cover.

If

wing nut is used that does not require copper

washer, make sure lower flange area of wing nut properly seals around hole in cover.

Wing nuts must

be finger tightened 1/2 to 1 full turn after nut contacts cover.

Do not overtighten.

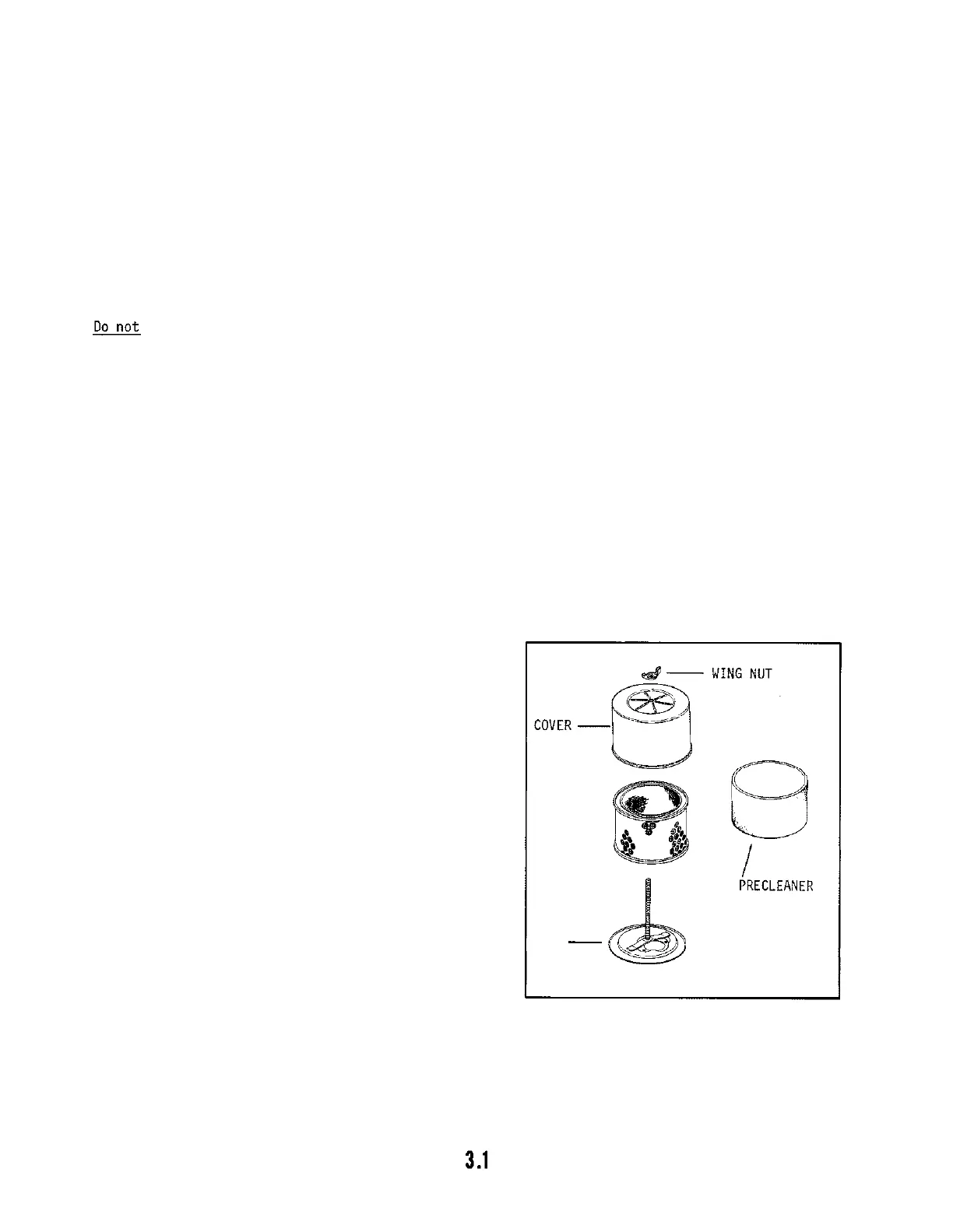

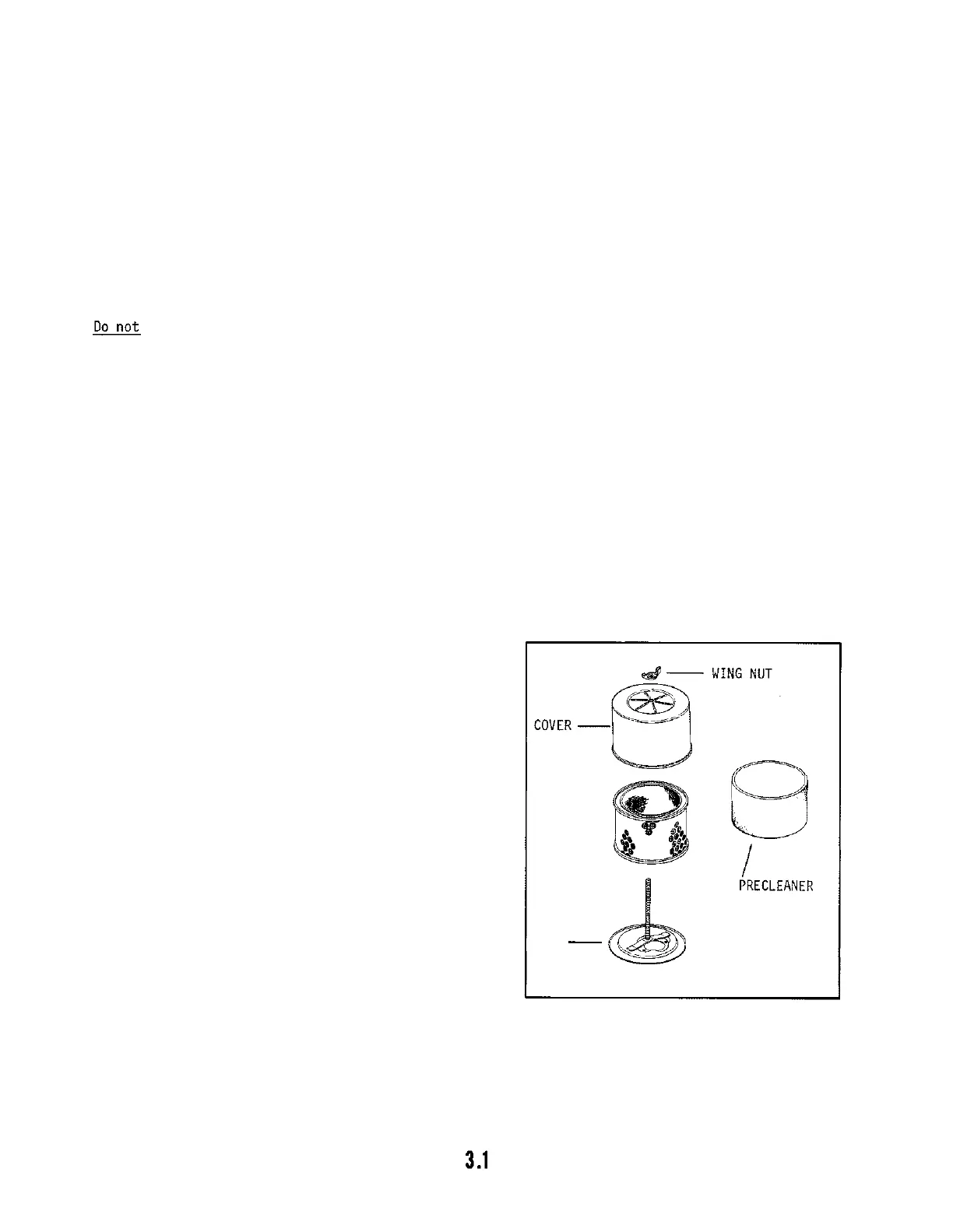

Precl eaner

Some models are equipped with a precleaner.

Pre

-

cleaners extend the useful life of the paper air

cleaner element by removing coarse particles.

Precleaners should be washed and oiled every

25

operating hours, or more often under extremely dirty,

dusty conditions, as follows:

1. Remove precleaner from air cleaner element and

wash in warm water with detergent.

2. Rinse thoroughly until all traces of detergent

are eliminated and squeeze away excess water.

Air dry. (Do not wring precleaner.)

3. Soak in fresh clean engine oil and squeeze out

excess oil.

4. Reinstall precleaner over air cleaner element.

DRY TYPE

ELEMENT

-

BASE

FIGURE 3

-

1

--

TYPICAL DRY TYPE AIR CLEANER

Loading...

Loading...