ENGINE RECONDITIONING

All parts should be thoroughly cleaned

--

dirty parts cannot be accurately gauged or properly

inspected for wear or damage.

There are many commercial cleaners available that quickly remove

grease, oil and grime accumulation from engine parts.

If such a cleaner is used, make sure that all

trace of the cleaner is removed before the engine is reassembled and placed in operation.

Even small

amounts of these cleaners quickly break down the lubricating properties of engine oils.

CYLINDER

BLOCK

1. Inspection

A.

Gasket surfaces

-

Check all surfaces to make sure that they are free of gasket fragments.

Surfaces180 be free of deep scratches or nicks.

B.

Bearings, Races, Transfer Sleeves

-

On K482, K532 models, carefully inspect sleeve type

bearing that is press fitted in block.

On two sleeve bearing models, also inspect sleeve

hearing in closure plate at this same time.

On

K662 models, check oil transfer sleeves

and outer bearing races. If visual inspection of these parts reveals no evidence of scoring,

grooving or scuffing,

check further to see if wear is within limits.

Do not remove parts

unless replacement is necessary.

If crankshaft has to be reground, undersize hearings

(K482, K532) and transfer sleeves (K662) will have to be used regardless of condition of old

parts. Running clearance of transfer sleeves on

K662 is .000-. 0025

"

.

C. Bushings (Camshaft)

-

Check bushings

for

signs of scuffing, scoring and excessive wear.

See Clearance Section for wear limits. Precision type bushings, which do not require line

reaming, are available if replacement

is

necessary.

D.

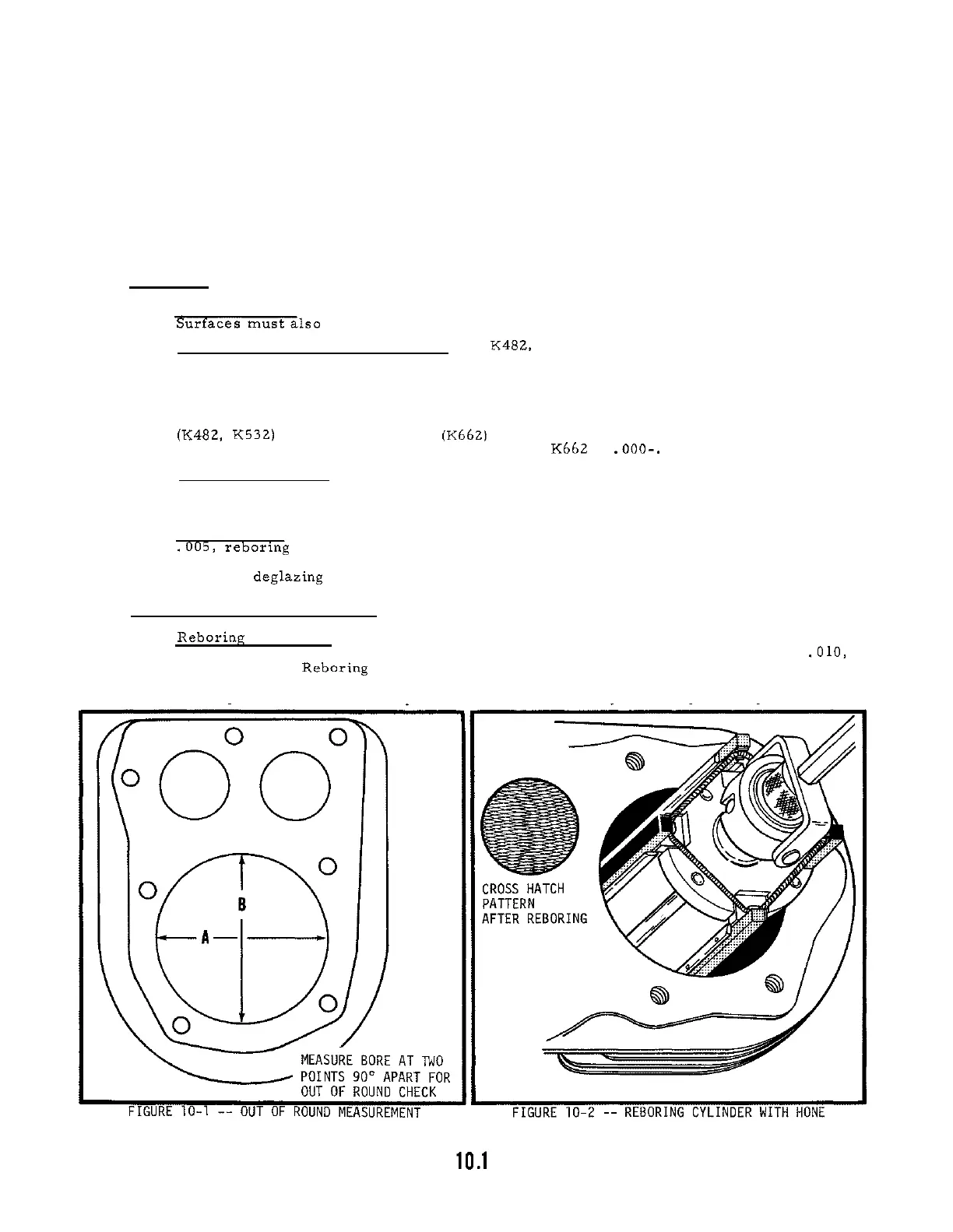

Cylinder Bore

-

If badly scored, excessively worn or tapered or out of round more than

.005, reboring is necessary. Use an inside micrometer to determine amount of wear (See

Fits and Clearance Section). If cylinder bore is not damaged and

is

within tolerances,

only light

deglazing may be necessary.

2.

Reconditioning

-

Cylinder Block

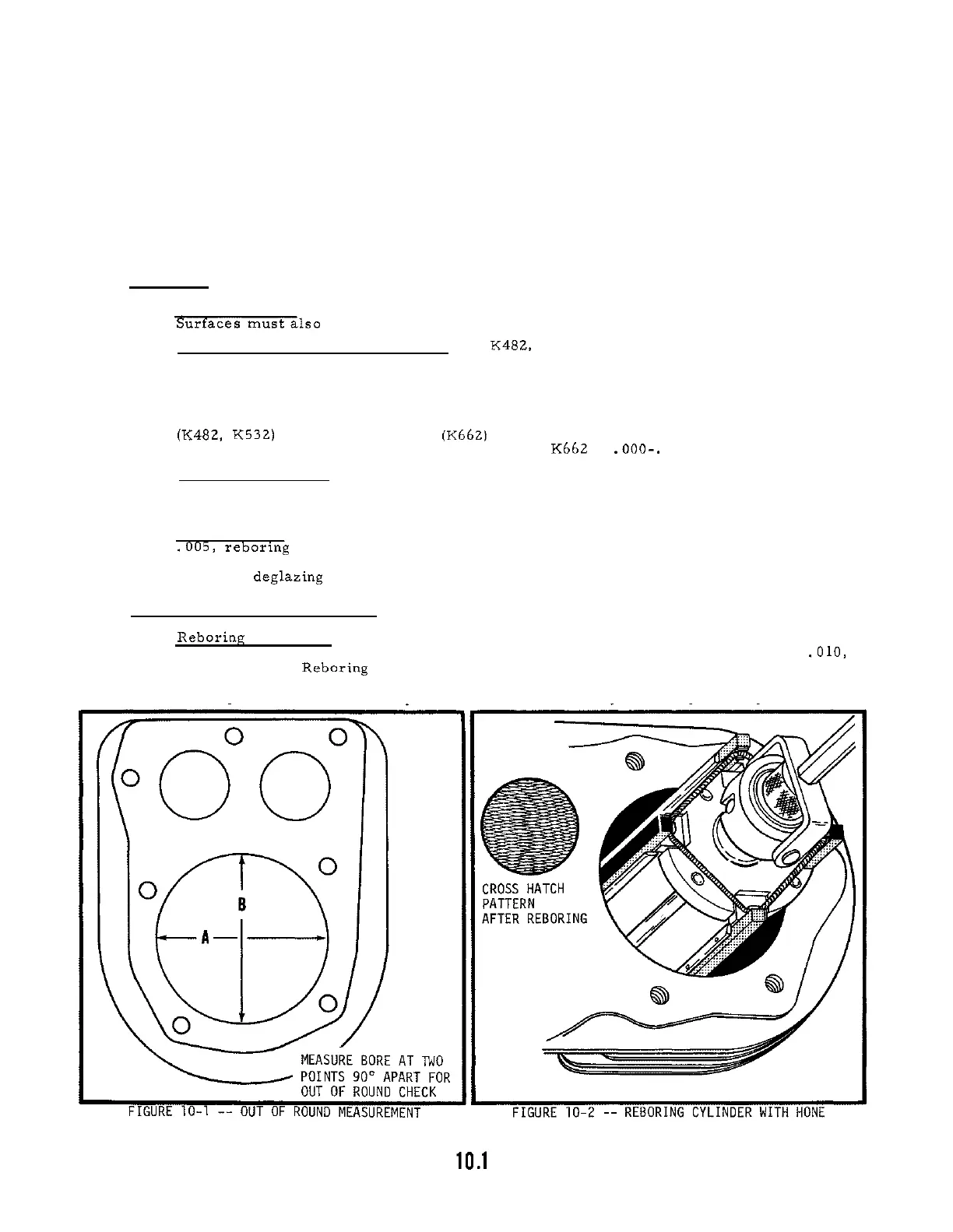

A.

Reboring Procedure

-

See Clearance Section for original cylinder bore size. Use an

inside micrometer to measure wear then select nearest suitable oversize of either

.010,

,020 or ,030

"

. Reboring to one of these oversizes will allow usage of the available over

-

size piston and ring assemblies. While most commercial cylinder hones can be used with

either portable drills or drill presses, the use of a low speed drill press

is

preferred as

Loading...

Loading...