IGNITION TIMING-K482, K532 ENGINES

On K482 and

K532

engines, the breaker point assembly

is

mounted on the governor.

The breaker

rod rides on a cam on the governor drive shaft.

The governor is therefore timed to the engine and

must be

retimed if it has been removed for any reason

(see

Governor Instructions in Section

5).

The

governor also incorporates an automatic spark advance

-

retard mechanism.

Retard is

8' BTDC while

the advance point is 27' BTDC.

The advance spark point is marked

"SP" on the flywheel of the engine.

Use

the following procedure to adjust breaker point gap:

1. Remove breaker point cover.

2.

Turn engine over until breaker points are full open

--

measure gap with feeler gauge.

Maxi

-

mum opening should be ,020

"

. Adjust by loosening gap adjusting screw then insert screw

-

driver blade in adjusting notch to shift movable plate until ,020" maximum opening is

attained. Retighten gap adjusting screw and replace breaker point cover after initial

adjustment.

3.

Follow up with the final or precision adjustment using a timing light.

Final adjustment

is made

by shifting position of governor

--

refer to procedure below.

Several different types of timing lights are available

--

follow the manufacturer's instructions for

the particular type of timing light used. The following procedure can he used

with* timing lights.

Rotating the governor advances or retards the timing depending on which way the unit is turned.

1.

If boot type lead is used, remove hoot at

#l

cylinder (nearest flywheel) then wrap one end

of a short piece of fine wire around spark plug terminal.

Reconnect boot to terminal

so

that free end of the wire can protrude under the boot.

(Step 1 applies to timing lights hav

-

ing alligator clips.

)

2.

Connect one of the timing light leads to the wire protruding from under the boot.

3.

Connect second timing light lead to hot (ungrounded) side of battery

-

-

see timing light

instructions for proper

ba;tery size, wir- connections, etc.

4.

Connect third timing light lead to common ground.

5.

Before starting, rotate engine until '-5P" mark is observed in timing sight hole

--

chalk

marK the line for easy reading.

6.

Start engine and operate at 1200

RPM

or

above.

Aim timing light into sight hole

--

light

should flash just as

"SP" mark is centered in sight hole.

If light flashes before mark is

centered, timing is

overadvanced.

If light flashes after mark is centered, timing is

retarded.

7.

To adjust, loosen (do not remove) governor flange mounting capscrews and shift or rotate

until timing mark is exactly centered as light flashes.

Retighten flange mounting screws

after exact timing is achieved.

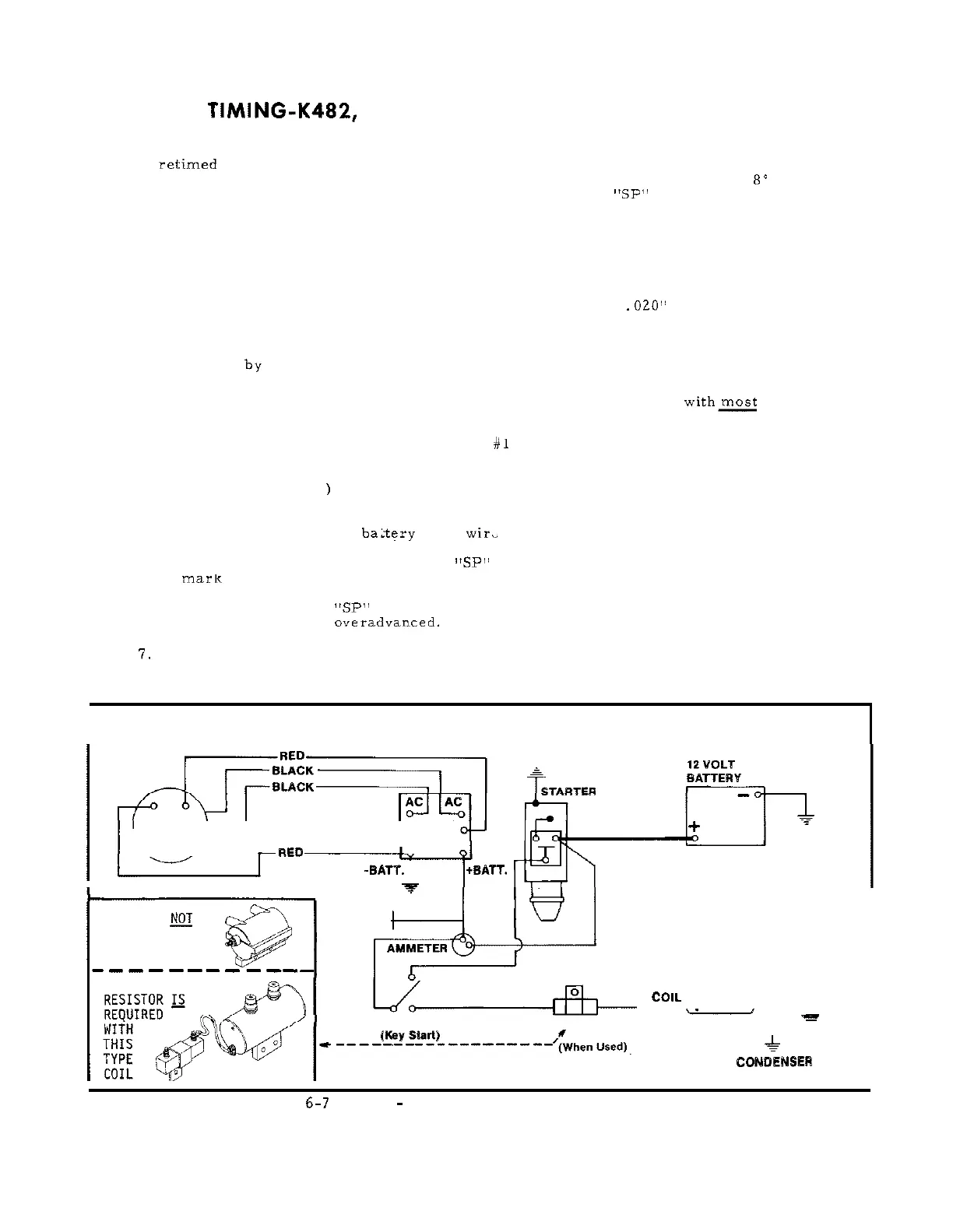

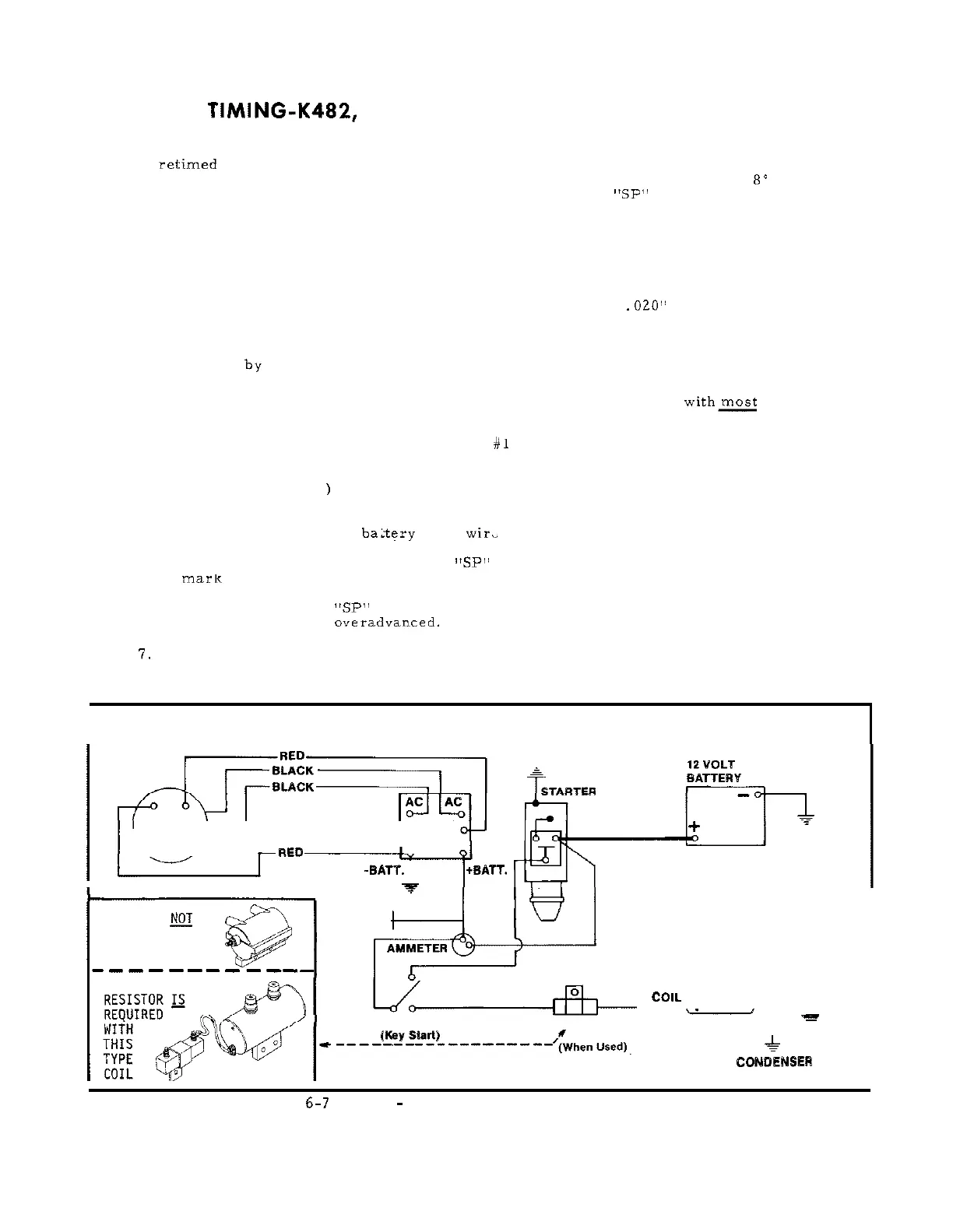

REGULATOR

FLYWHEEL

REG.

ALTERNATOR

-0ATT. +BATT.

-

-

REG.

RESISTOR

REQUIRED

$J

WITH

@

1

THIS

COIL

-----------

LIGHTS

SWITCH RESISTOR

SPARK SPARK

PLUG

BREAKER

POINTS

COIL

-

=

*

CONDENSER

I

I

I

FIGURE

6-7

--

K482

-

30 AMP ALTERNATOR SYSTEM, WIRING DIAGRAM

6.8

Loading...

Loading...