108

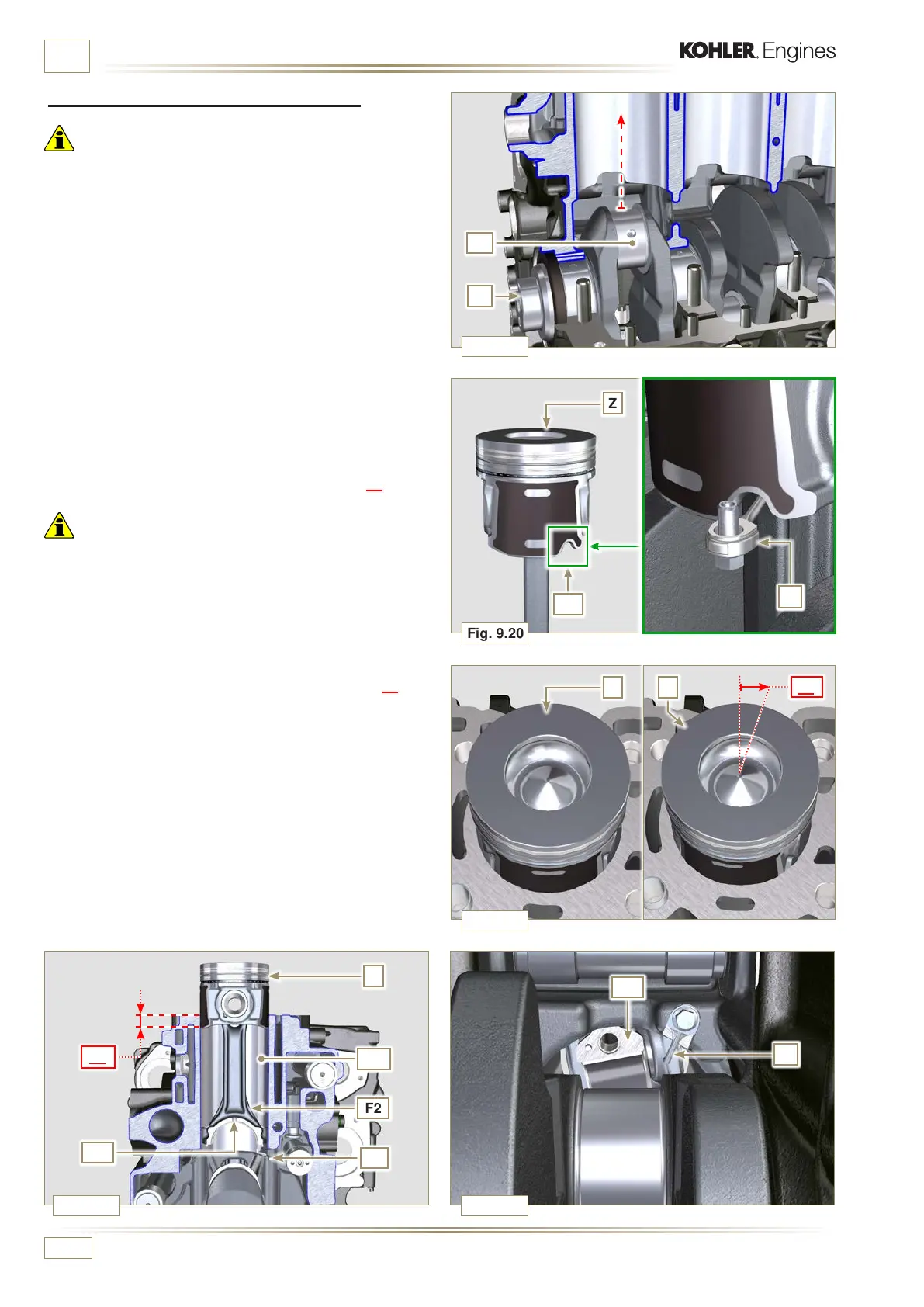

Fig. 9.20

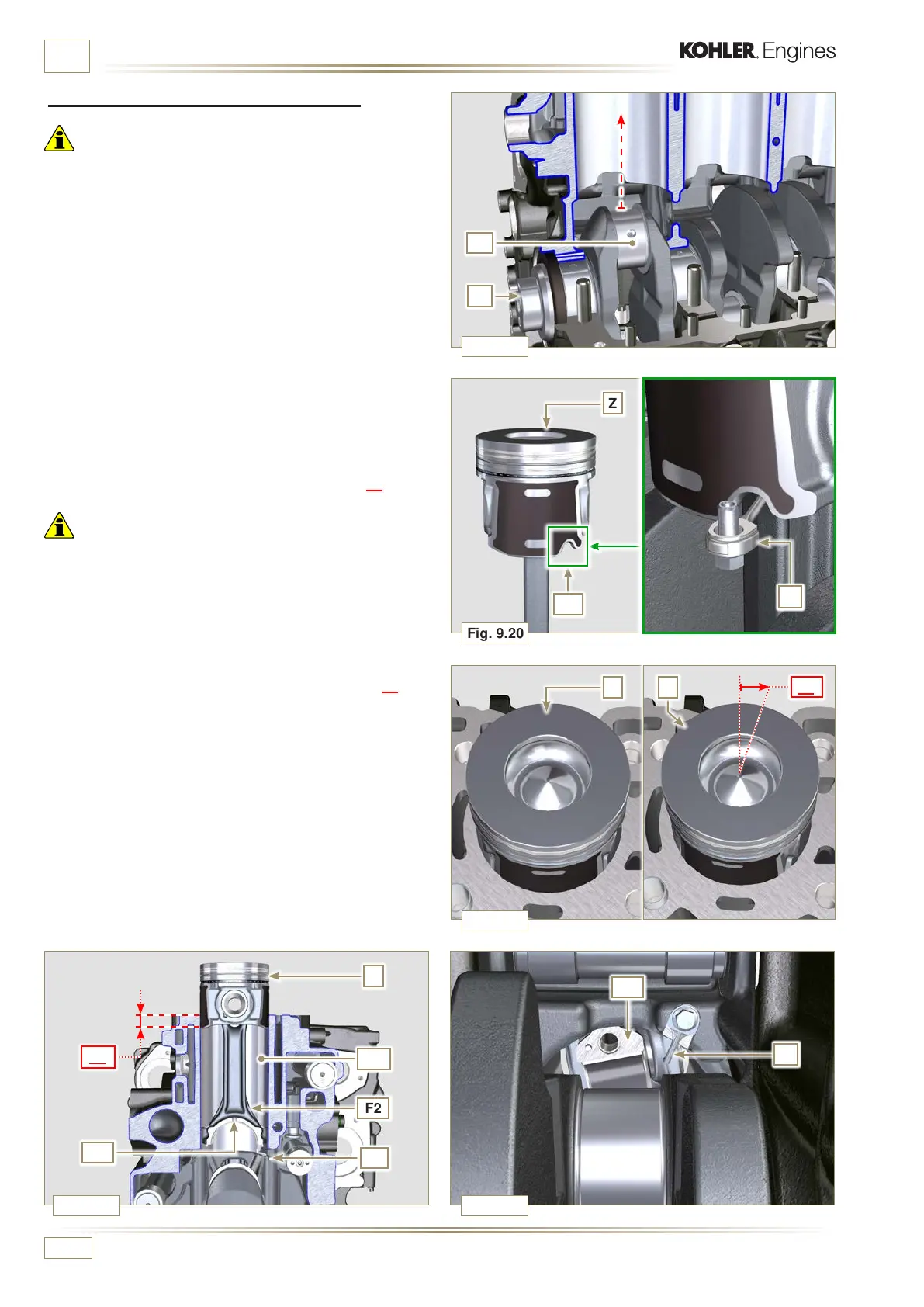

F2

G

Z

F2

V1

U1

T2

Fig. 9.22 Fig. 9.23

W1

T3

Z Z

Z

Fig. 9.21

J1

M

K1

G

Fig. 9.19

ED0053030410

ASSEMBLY INFORMATION

2 - Lubricate the piston skirt and rings Z.

3 - Check that the half-bearing U1 is mounted correctly and

lubricate it thoroughly.

4 - Using the piston ring compression pliers, insert the piston

inside the cylinder W1 by around 10mm (height T2).

Important

• Make sure you are at the stage described in Point 1.

• Piston Z must be assembled with notch K1 on the side of the

skirt facing oil spray nozzles G.

5 -

Rotate the piston Z by 10° counter-clockwise with respect

to its correct assembly position (Fig. 9.21 - height T3).

NOTE: Doing this prevents the impact between the connecting

rod F2 and the sprayer G.

9.3.10 Piston and connecting rod assembly

Important

• Before assembling the piston and connecting rod assemblies,

execute the controls described in Par. 8.5.

1 - Rotate the crankshaft M by moving the crankpin J1 to a

TDC position of the affected cylinder.

Loading...

Loading...