117

C

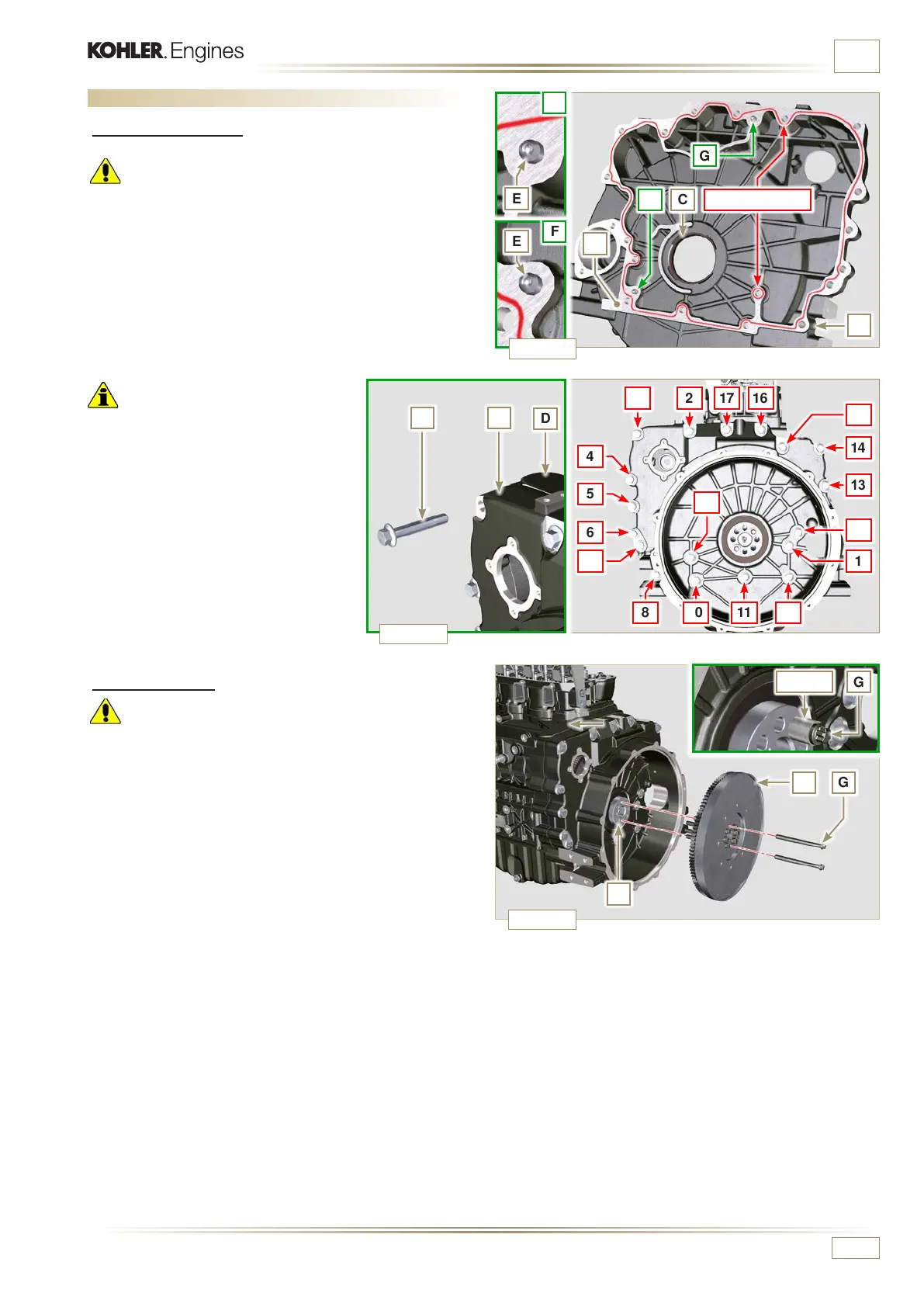

E

E

D

G

G

F

F

B

A

AF

1

13

12

14

15

161723

4

5

6

7

8 10

9

11 18

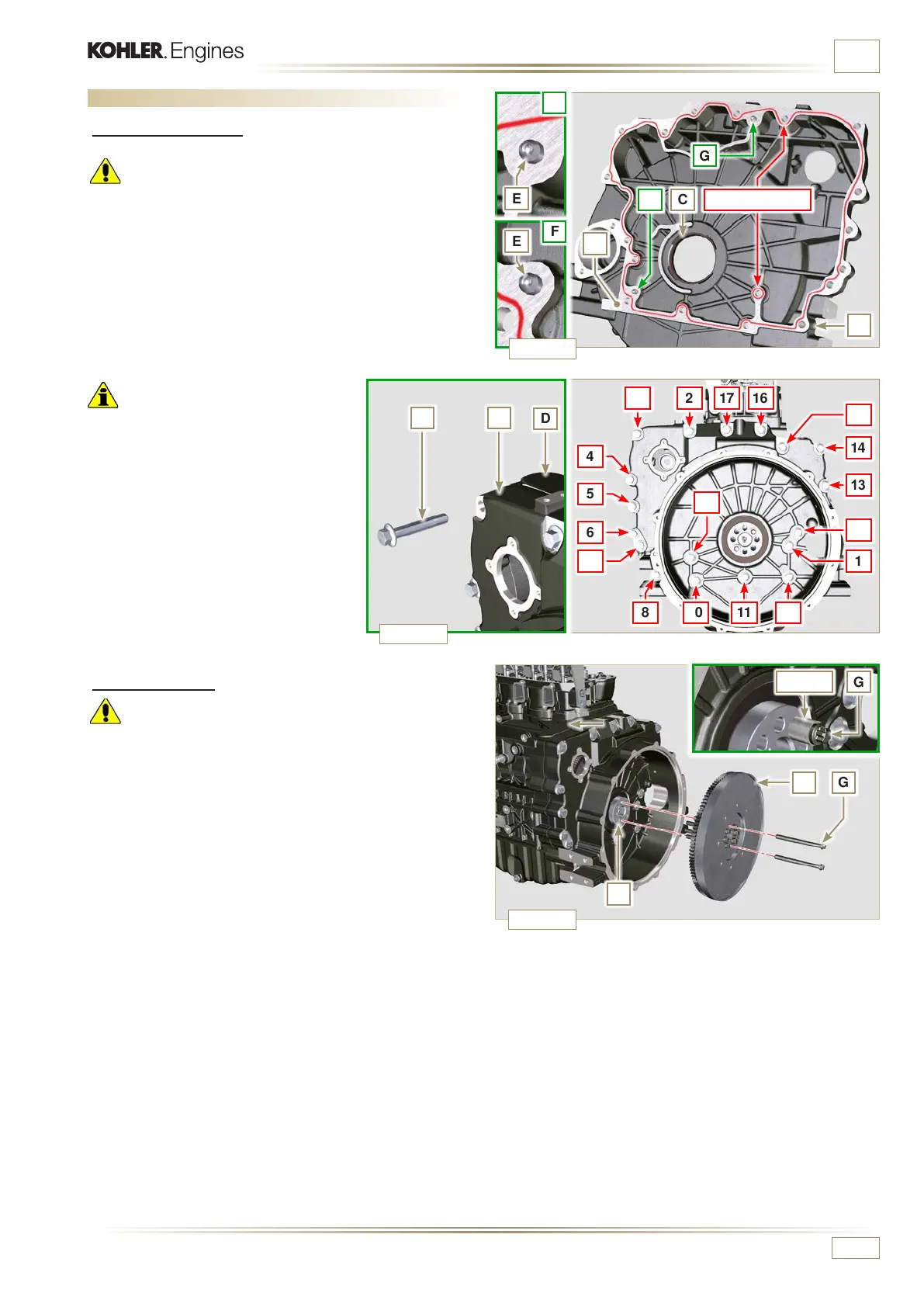

G

L

G

ST_41

H

LOCTITE 5660

Fig. 9.55

Fig. 9.56

Fig. 9.57

ED0053030410

ASSEMBLY INFORMATION

9.7 Flange unit assembly

9.7.1 Bell housing

Danger

• Bell A is very heavy; pay special attention during assembly

operations to avoid dropping and causing serious risks to

the operator.

1 - Apply a bead of approx. 2.5 mm of sealant (Loctite 5660)

on the surface B of the bell A.

2 - Assemble bell A onto crankcase D, complying with

reference taper pins E (ST_45).

9.7.2 Flywheel

Danger

• Flywheel H is very heavy; pay special attention during

assembly operations to avoid dropping and causing serious

risks to the operator.

1 - Loosen capscrews G and remove tool ST_41.

2 - Position flywheel H onto crankshaft L by means of tool

ST_43 - ST_46.

3 - Apply "Molyslip AS COMPOUND 40" on the threads and

under the head of capscrews G and manually tighten them

until their stop.

4 - Secure flywheel H with capscrews G (tightening torque 60

Nm).

5 - Once again, tighten capscrews G (2 cycles with tightening

torque 130 Nm).

Important

• Failure to adhere to the assembly

procedures may compromise the

functionality of the engine, and also

cause damage to persons and property.

• Always replace and lubricate the gasket

C wit h o i l, eve r y t i m e t h ey are a s sembled

(the gasket C is to be mounted after the

operation at point 4, ST_47).

3 -

Apply the screws F by hand without

tightening them.

4

- Tighten the screws F following

the tightening sequence indicated

(tightening torque 75 Nm).

Loading...

Loading...