66

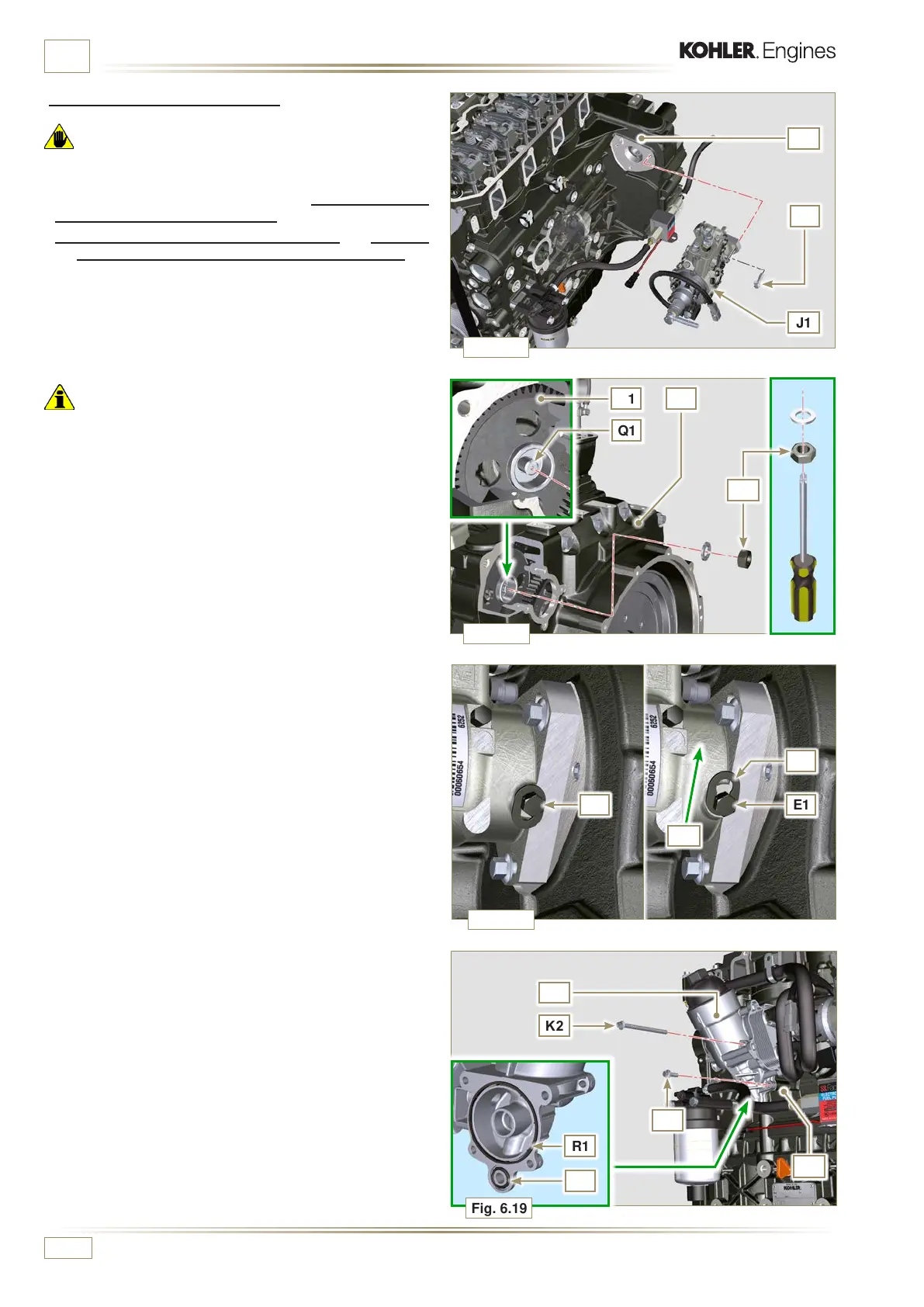

Fig. 6.16

J1

J2

Q1

M1

G2

E1

F1

E1

Fig. 6.17

M1

Fig. 6.18

D1 S1

C1

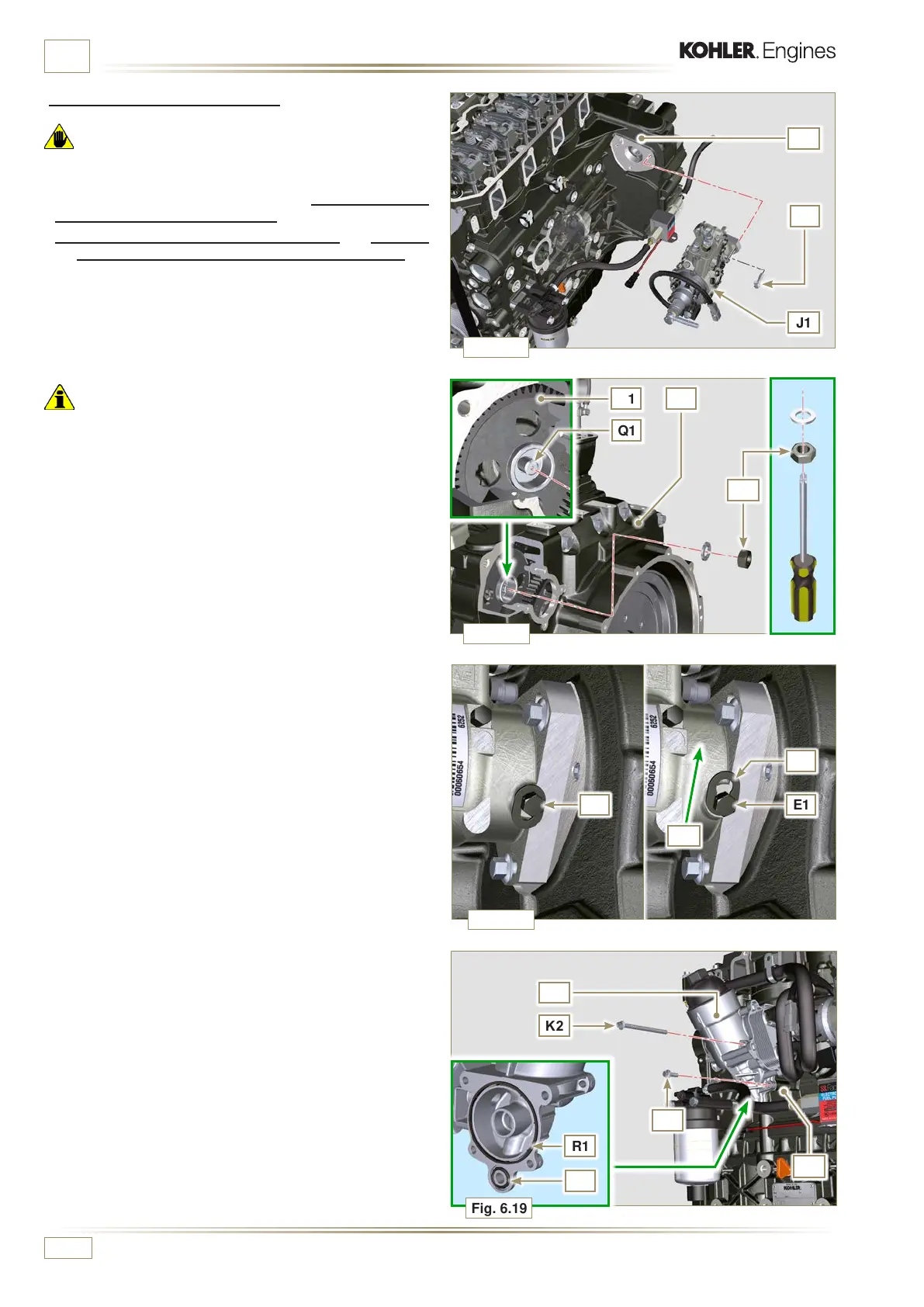

Fig. 6.19

R1

R2

K1

K2

L1

ED0053030410

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

6.1.6 Injection pump assembly

Important

• Before assembling the new pump J1, make sure that plate

F1 can move freely and that fastening capscrews E1 are not

loose (the pump sold as a spare part is supplied with the

cylinder injection timing blocked N° 1).

• Ensure that the coupling surfaces on shaft Q1 and gear

D1 are free from impurities and lubrication residues.

• Remove the guard cap only when the pipes are reconnected.

• Do not remove the tool ST_30.

1 - Mount the injection pump J1, inserting the shaft Q1 in the

gear D1.

Important

• Always change screws J2 with new ones or apply Loctite

2701 to the threads.

2 - Clamp the screws J2 on the crankcase M1 (tightening

torque at 25 Nm).

3 - Remove the tool ST_13.

4 - Ensure that the correct advance value has remained

unchanged, tighten nut C1 on shaft Q1 (as shown in Fig.

6.17, you are allowed to use a screwdriver to guide nut C1

onto shaft Q1 in order to prevent it from accidentally falling

inside carter S1 - tightening torque at 140 Nm).

5 - Undo the capscrew E1 and shift the slotted plate F1 in the

direction of arrow G2.

6 - Tighten screw E1 (tightening torque to 5.5 Nm).

The injection pump is unlocked.

7 - Remove the tool ST_30 and ST_34.

8 -

Assemble Oil Cooler L1 onto crankcase M1 by means of

capscrews K1 and K2.

NOTE: Always replace the gasket R1, R2 at each assembly.

Loading...

Loading...