69

Y1

E2

H6

A

B

H

F

G

C

D2

E

P

Z1

M

M1

M2

L

B2

A2

N

D

E

C2 A2

ST_17 ST_17

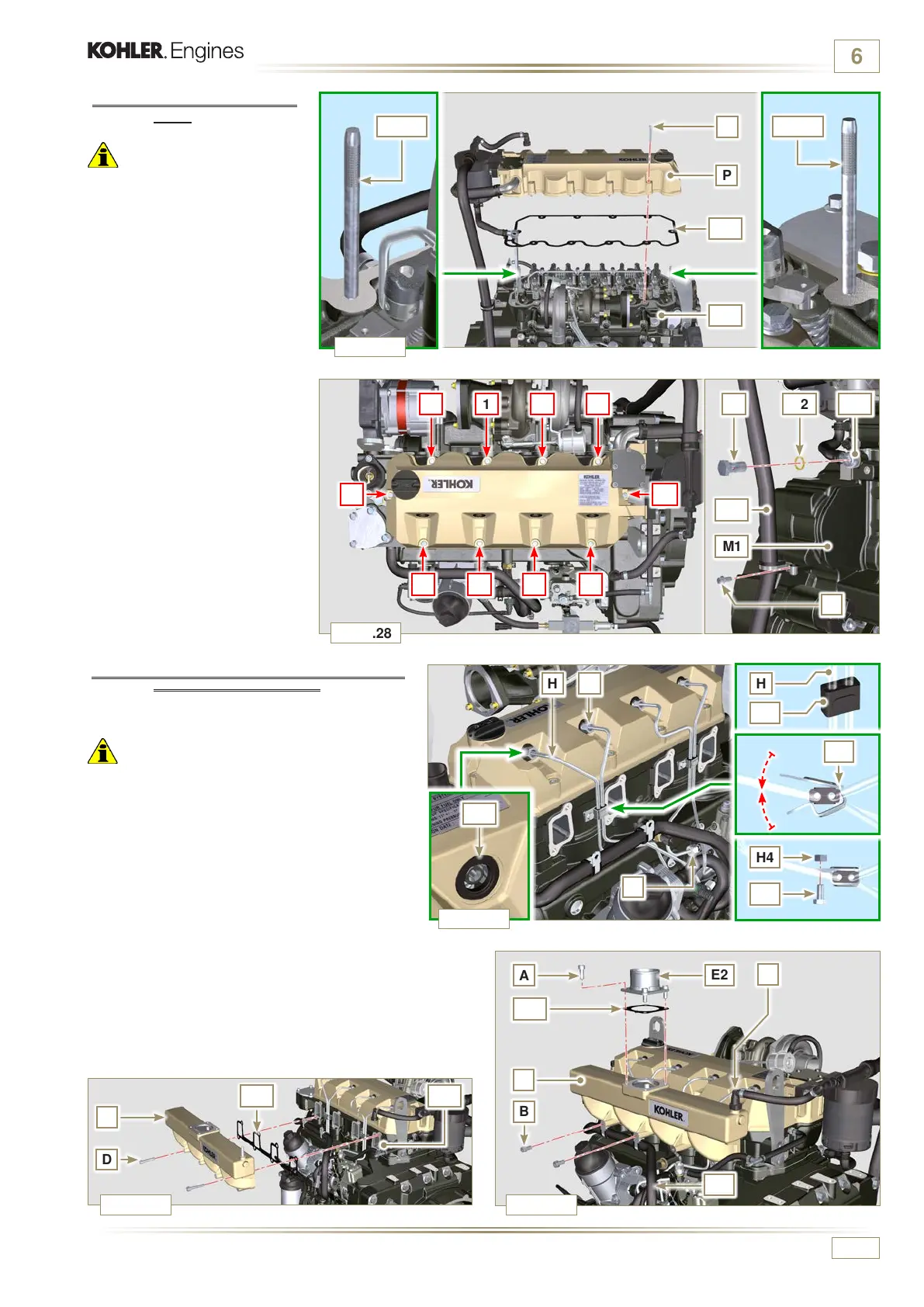

Fig. 6.28

Fig. 6.29

Fig. 6.27

Fig. 6.30 Fig. 6.31

1 3 75

8

9

4 2 6

10

H

H3

H4

H5

H2

M3

ED0053030410

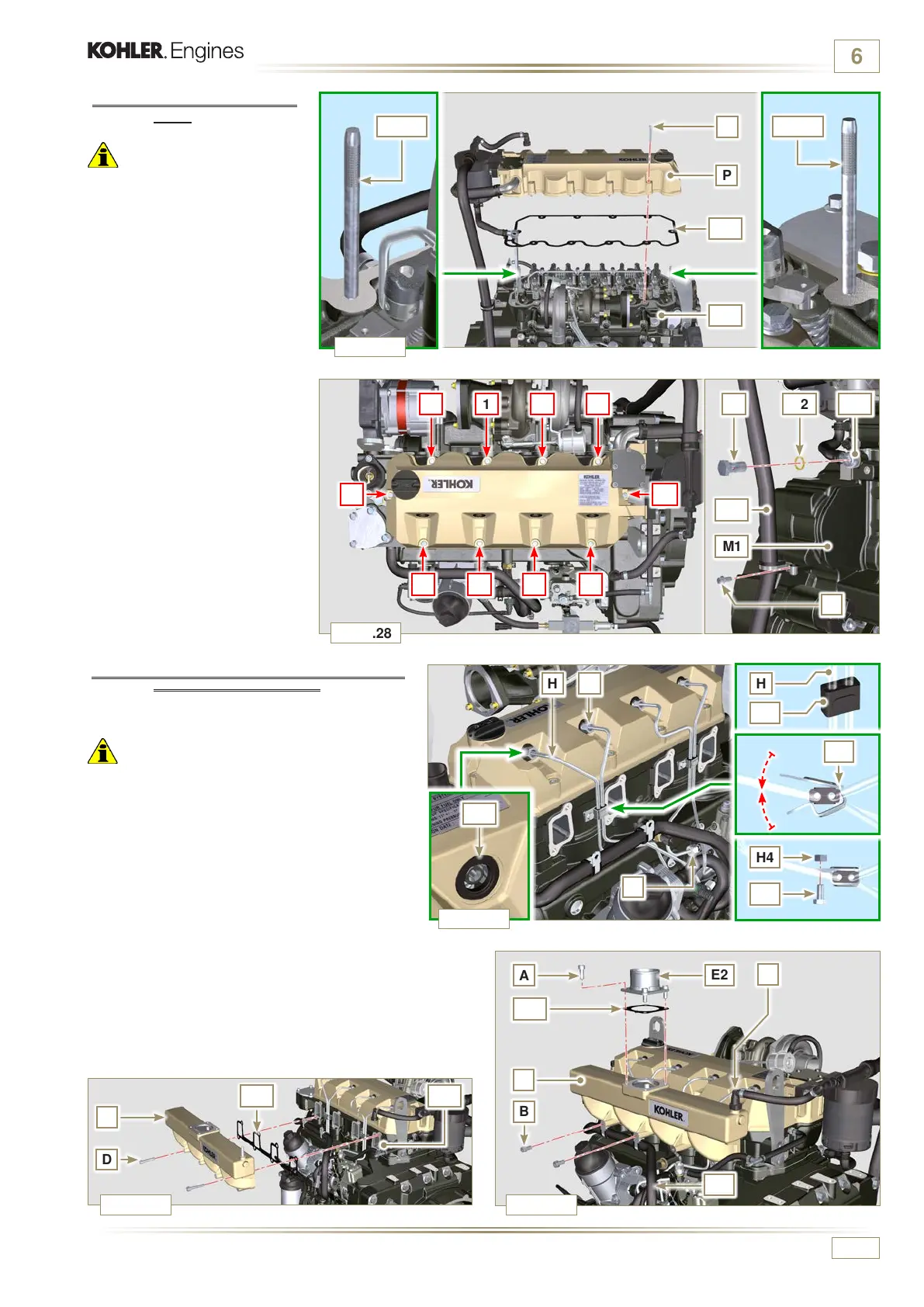

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

6.1.10 Installation of the fuel injector pipes

(pump injector/injectors)

1 -

Position pipes H on the injectors and on the

injector pump.

Important

• Tighten the nuts F and G manually, without

clamping them.

2 - Tighten

the nuts F and G

(tightening torque at 25

Nm).

3 - Secure tubes H by means of clamps H2,

assembling:

- H3 rubber element;

- clamp H2 on element H3;

- secure clamp H2 by means of capscrew H4

and nut H5 (tightening torque at 10 Nm).

4 -

Secure manifold E onto cylinder head A2 by

means of capscrews D, inserting gasket C2.

5 -

Secure suction line E2 onto manifold E by means of

capscrews A, inserting gasket D2.

6 -

Fit quick coupling C onto manifold E.

7 -

Fasten the pipe H6 on the manifold E with the screws B.

6.1.9 Assembly Rocker arm

cover

Important

• The gasket Z1 between the

rocker arm cover and the cylinder

head must always be replaced

every time it is disassembled.

1 - Position tool ST_17 onto the

head in correspondence with

the two fastening holes 9 and

10.

2 -

Position gasket Z1 and cap P

on cylinder head A2 matching

the holes of fastening

capscrews N with the aid of

the gudgeon guides ST_17.

3 -

Attach the rocker arm cover P

on the head A2 with the screw

N adhering to the tightening

sequence shown in Fig. 6.28

(tightening torque to 10 Nm).

4 -

Secure the hose M2 with the

screw L (tightening torque to

10 Nm).

5 -

Clamp the fitting M3 with the

screw M (tightening torque to

25 Nm) inserting the gasket

B2.

Loading...

Loading...