9

137

_07

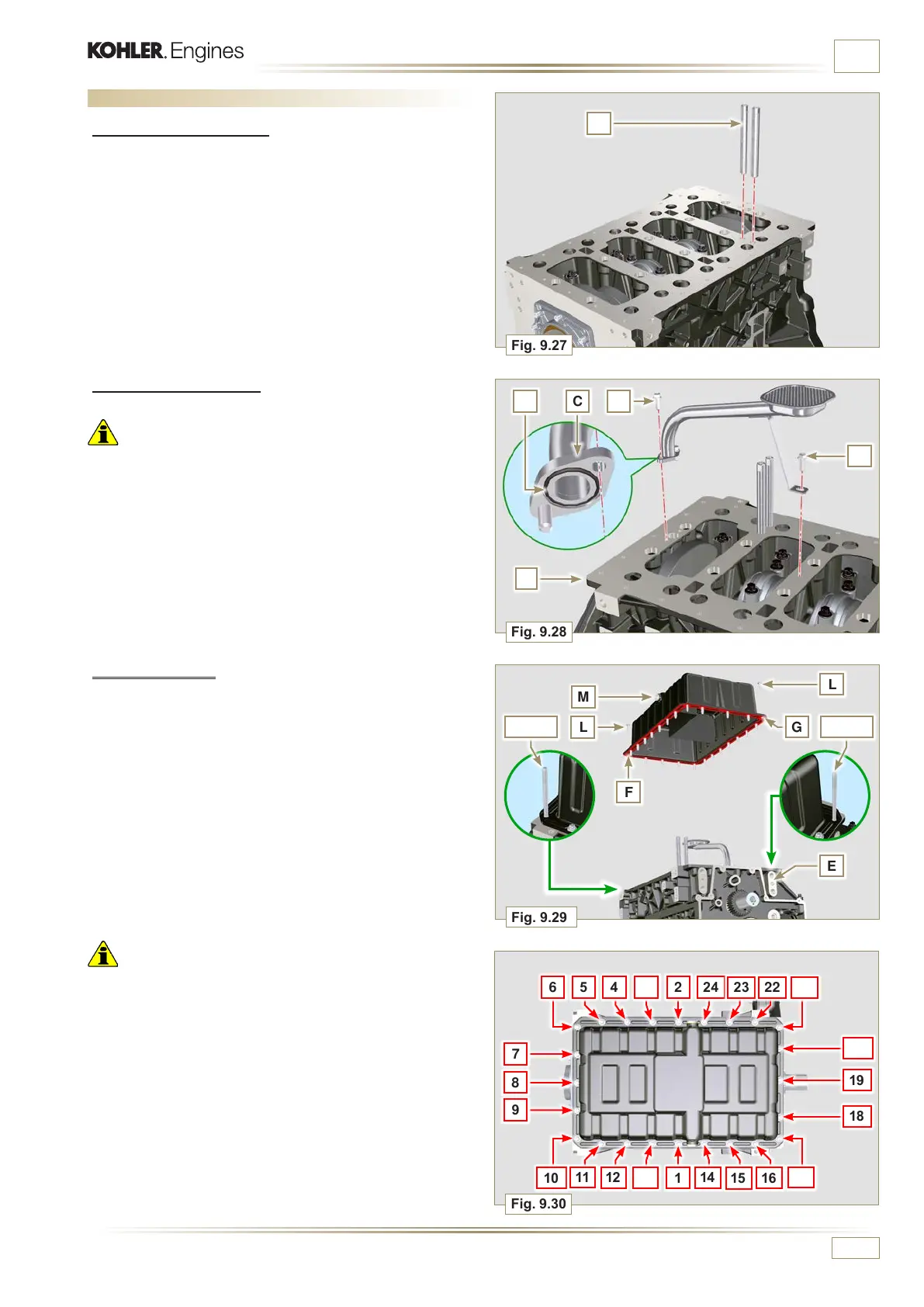

Fig. 9.27

A

Fig. 9.28

C

E

D

D

B

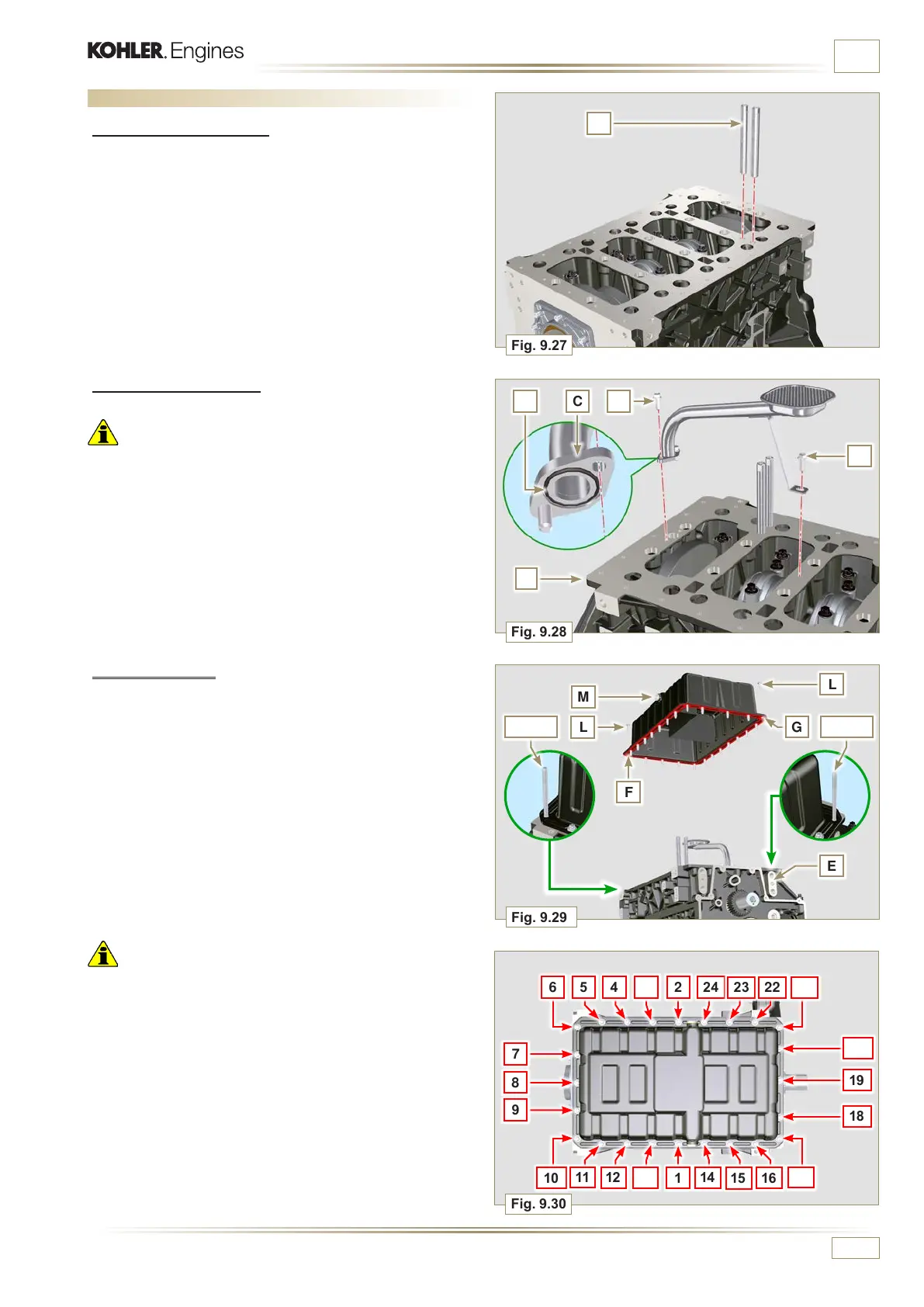

Fig. 9.30

1

14

15

16

17

18

19

20

2

24

23

22

21

10

11

12

13

9

8

7

6 5 4 3

Fig. 9.29

G

E

F

L

L

M

ST_18 ST_18

ED0053029590

ASSEMBLY INFORMATION

9.4.2 Oil suction pipe

Important

• It is mandatory to replace the gasket B after each assembly.

• Always replace capscrews D with new ones or alternatively

apply Loctite 2701.

1 - Insert the new gasket B in the seat of the oil suction hose

flange D.

2 - Secure the hose C on the crankcase E with the screws D

(tightening torque 10 Nm).

9.4 Oil sump unit assembly

9.4.1 Oil vapour pipes

1 - Apply Loctite 648 on the pipe threads A.

2 - Screw and tighten the pipes A (tightening torque of 15

Nm).

9.4.3 Oil Sump

1 - Ensure that the contact surfaces F of the oil sump G and

the crankcase E are completely clean.

2 - Apply a bead of approx. 2.5 mm of sealant (Loctite 5660)

on the surface F of the oil sump G.

3 - Position the oil sump G on the crankcase E in line with the

fastening holes (use the aid of tool ST_18).

Important

• Tighten the screws L, strictly following the sequence and

tightening torque indicated.

4 - Tighten the screws L following the sequence indicated

(tightening torque 25 Nm).

5 - After tightening all of the screws, loosen screw n°1 and re-

tighten it to the torque value specified in step 4.

6 - Check that the oil drain plugs M are tight (tightening torque

35 Nm).

Loading...

Loading...