9

138

_07

D

B

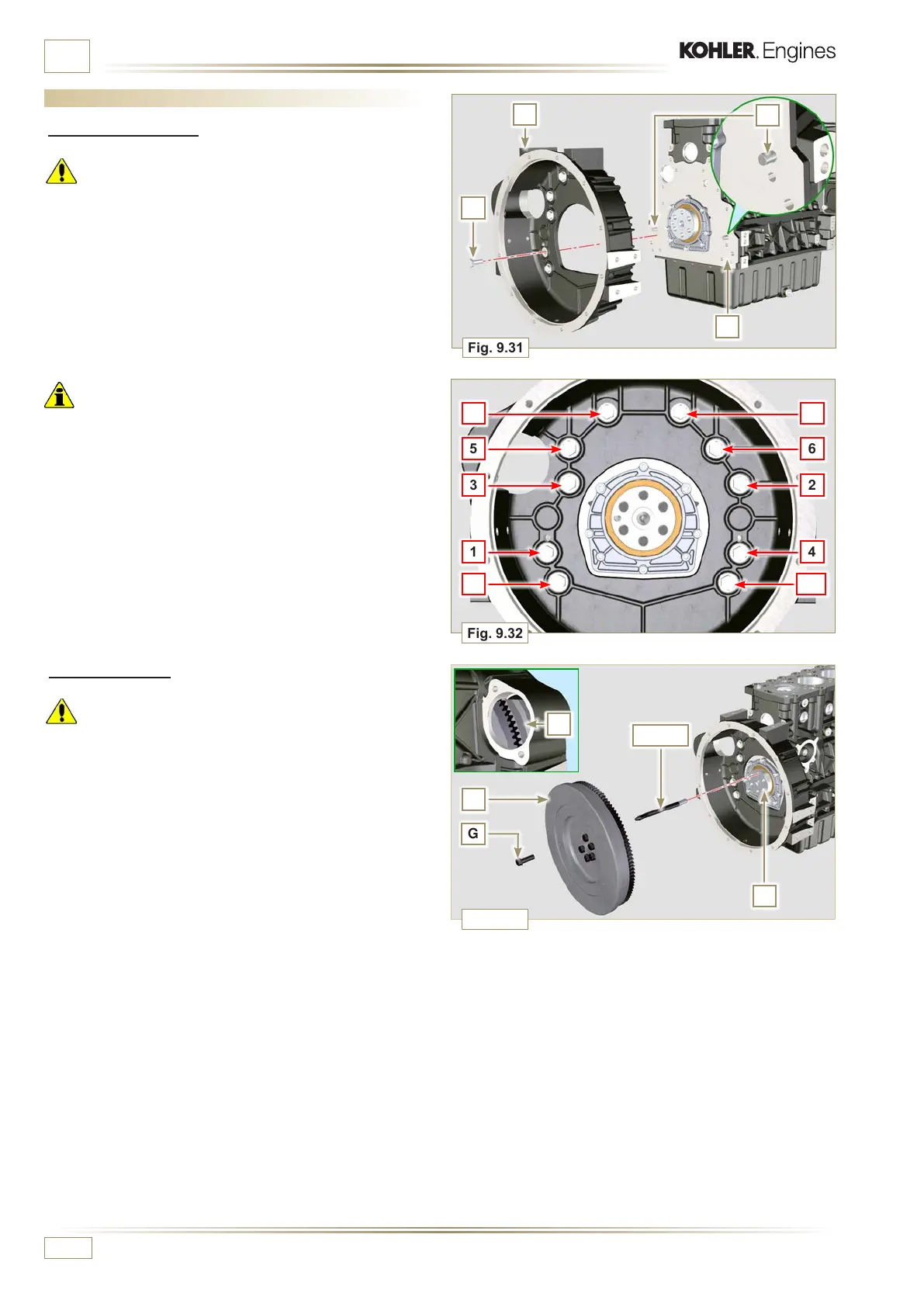

Fig. 9.31

A

C

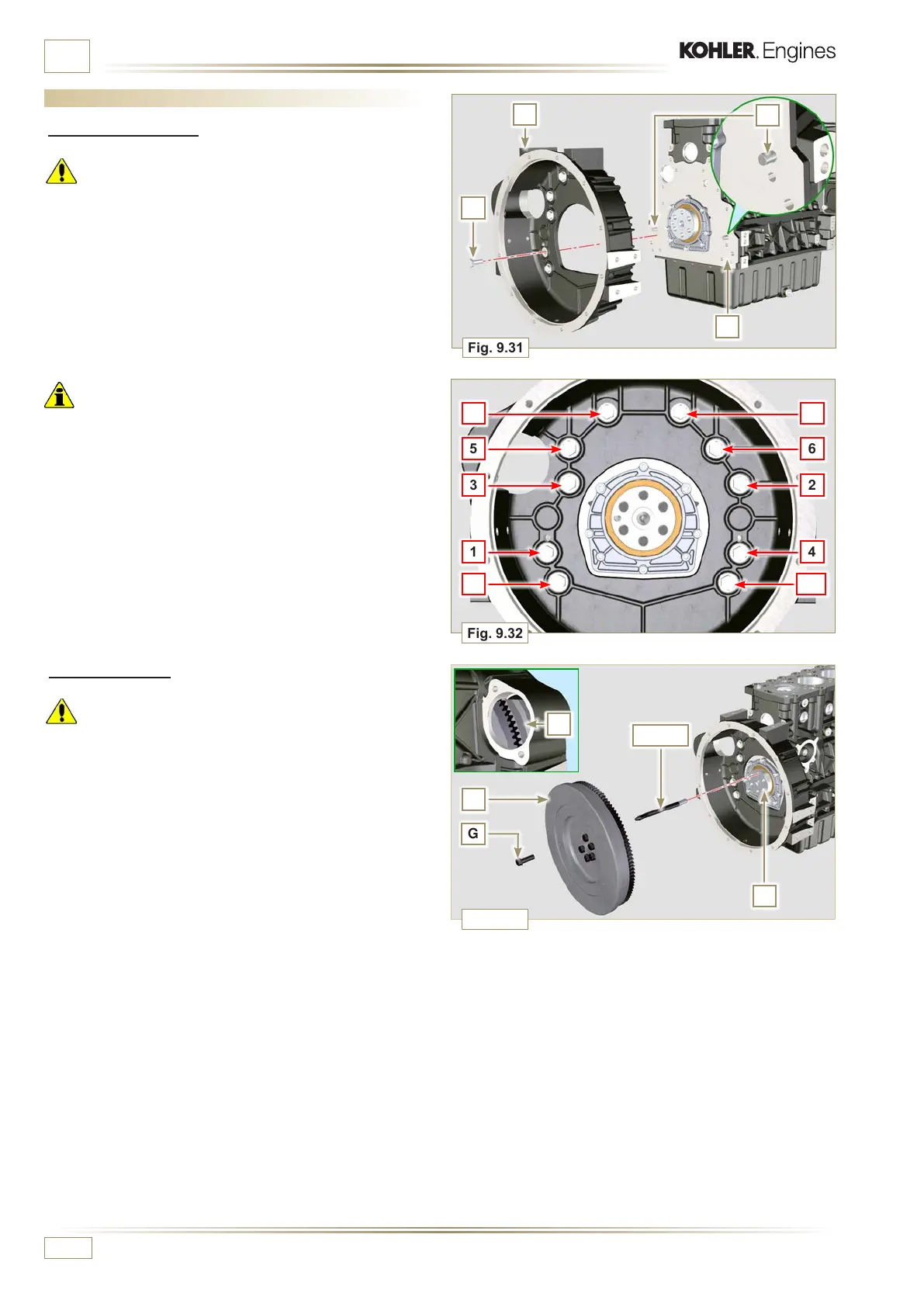

Fig. 9.32

1 4

3 2

5 6

9 8

7

10

G

F

F

Fig. 9.33

E

ST_09

H

ED0053029590

ASSEMBLY INFORMATION

9.5 Flange unit assembly

9.5.1 Bell housing

Danger

• Bell A is very heavy; pay special attention during assembly

operations to avoid dropping and causing serious risks to

the operator.

1 - Install the bell housing A in accordance with the reference

pins B on the base C.

9.5.2 Flywheel

Danger

• Flywheel F is very heavy; pay special attention during

assembly operations to avoid dropping and causing serious

risks to the operator.

1 - Screw the special tool ST_09 on the crankshaft E instead

of the screws G positioned higherup (Fig. 9.33).

2 - Insert the flywheel F on the crankshaft E using the tool

as a guide ST_09 and manually tighten all the screws G,

remove the tool ST_09 and install the last screw G.

3 - Mount the tool ST_34 in the seat of the starter motor H and

fit it with the two starter motor fixing screws.

4 - Tighten the screws G (tightening torque at 140 Nm).

Important

• Failure to adhere to the assembly procedures may

compromise the functionality of the engine, and also cause

damage to persons and property.

2 - Tighten the fastening screws strictly following the

tightening sequence indicated (tightening torque 50 Nm).

Loading...

Loading...