9

139

_07

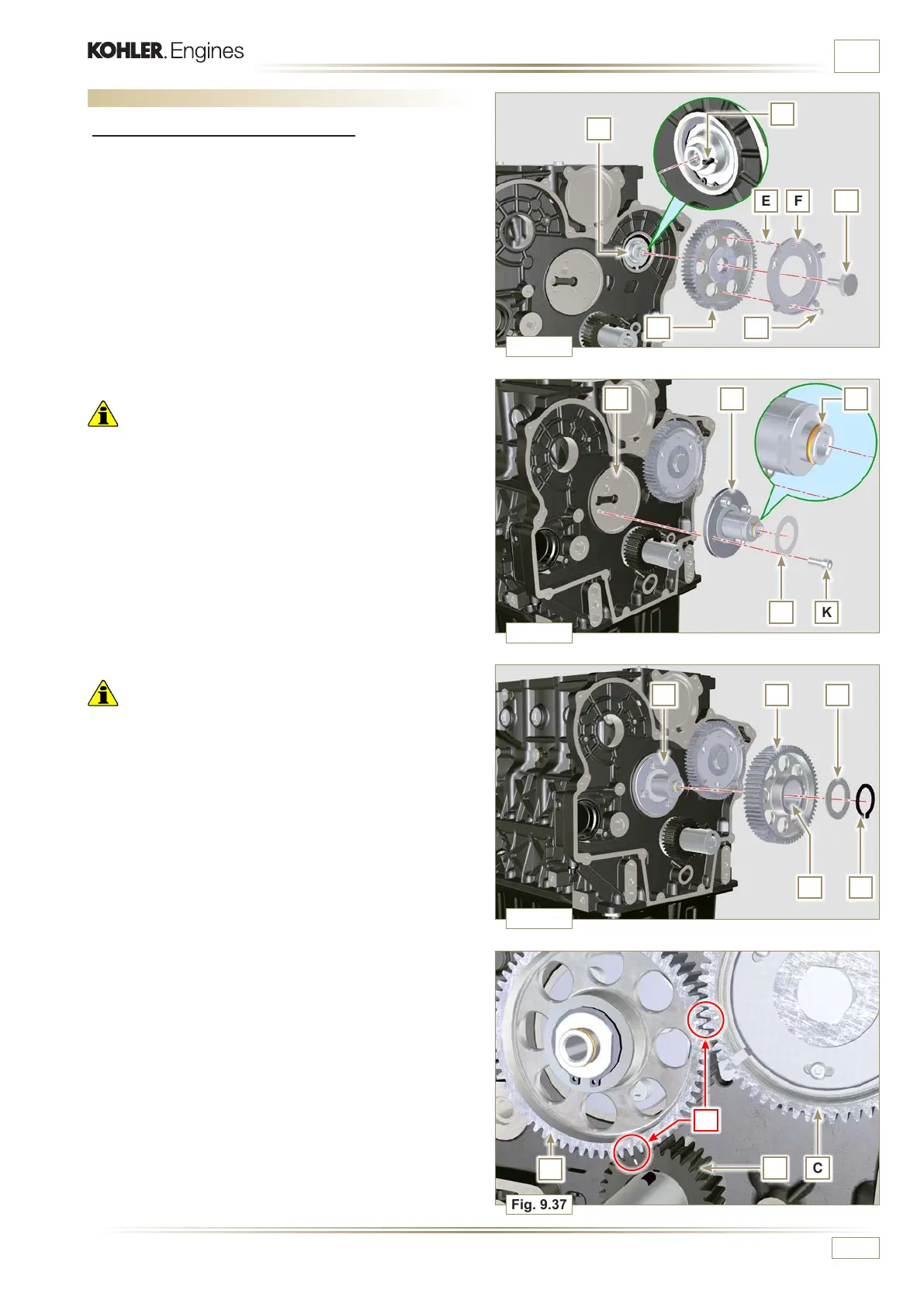

Fig. 9.37

P

CS

W

Fig. 9.36

PH Q

RN

Fig. 9.35

H LJ

KM

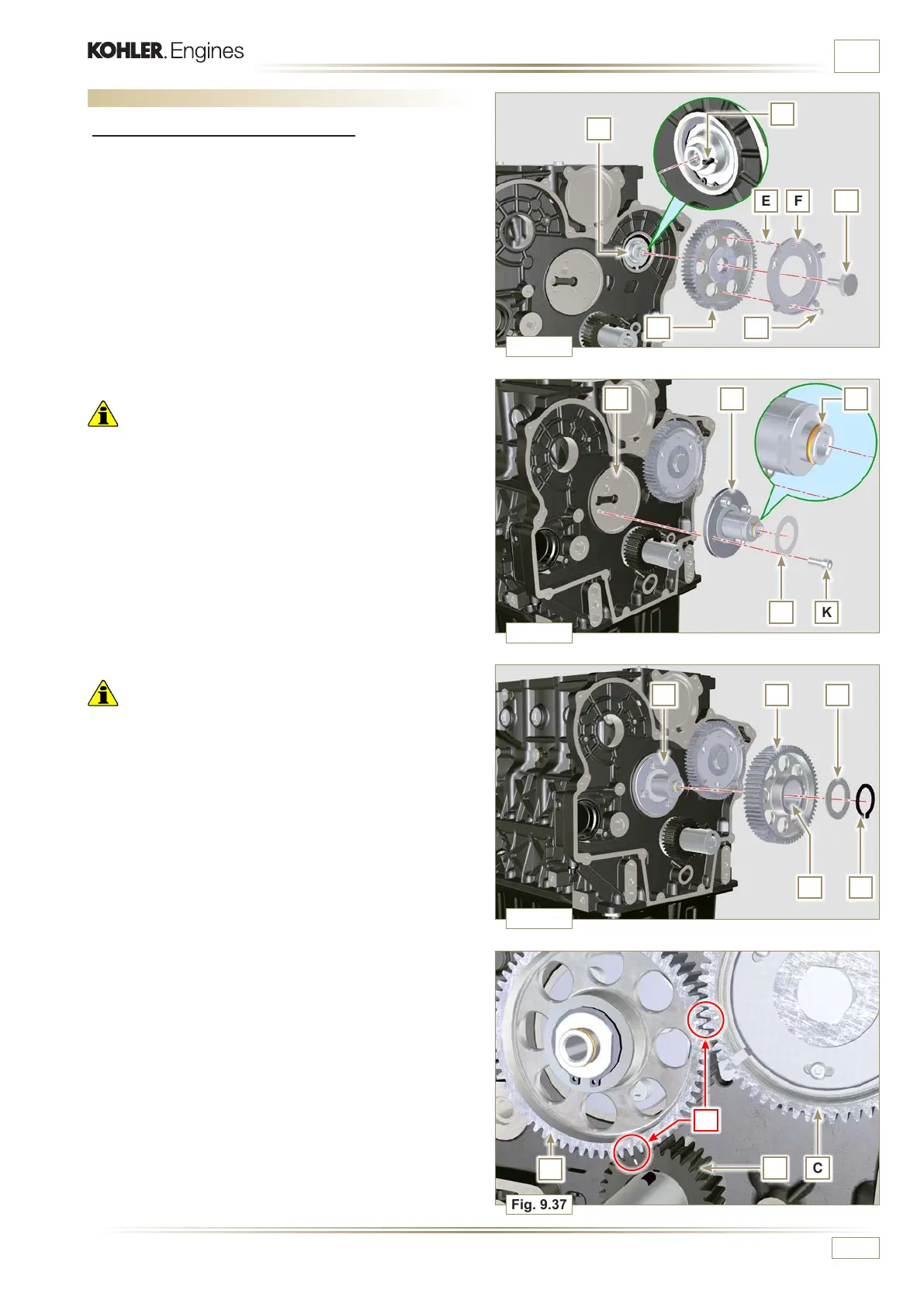

Fig. 9.34

A

E F D

C

B

G

ED0053029590

ASSEMBLY INFORMATION

9.6 Timing system gear assembly and injection pump

9.6.1 Timing system gear assembly

1 - Check that the key A is correctly fitted on the camshaft B.

2 - Position the gear C on the camshaft B adhering to the key

reference A.

3 - Screw capscrew D until the end.

4 - Insert the reference pin E on the gear C.

5 - Screw the encoder F with the screws G on the gear C

observing the plug E.

6 - Tighten the middle gear pin H, in the housing J of the

crankcase, with the screws K (tightening torque 25 Nm).

Important

• The fitting of the middle gear pin H has only one position, the

4 screw holes K are not equally spaced.

• Always replace the gasket L after each assembly.

7 - Insert the shoulder ring M.

8 - Check the integrity of the bushing N on the middle gear P,

and ensure that it is free from impurities.

9 - Thoroughly lubricate the pin H and the bushing N.

10 - Position the gear P on the pin H observing all the marks W

of the gears C and S, (Fig. 9.37).

Important

• Failure to comply with the marks W on the gears C, P and S,

causes engine malfunction and serious damage.

11 - Insert the shoulder ring Q and the lock ring R.

12 - Tighten the gear C with the screw D (Fig. 9.34 - tightening

torque at 100 Nm).

13 - Tighten the encoder F with the screws G on the gear C

(tightening torque at 5 Nm) observing the plug E.

Loading...

Loading...