9

145

_07

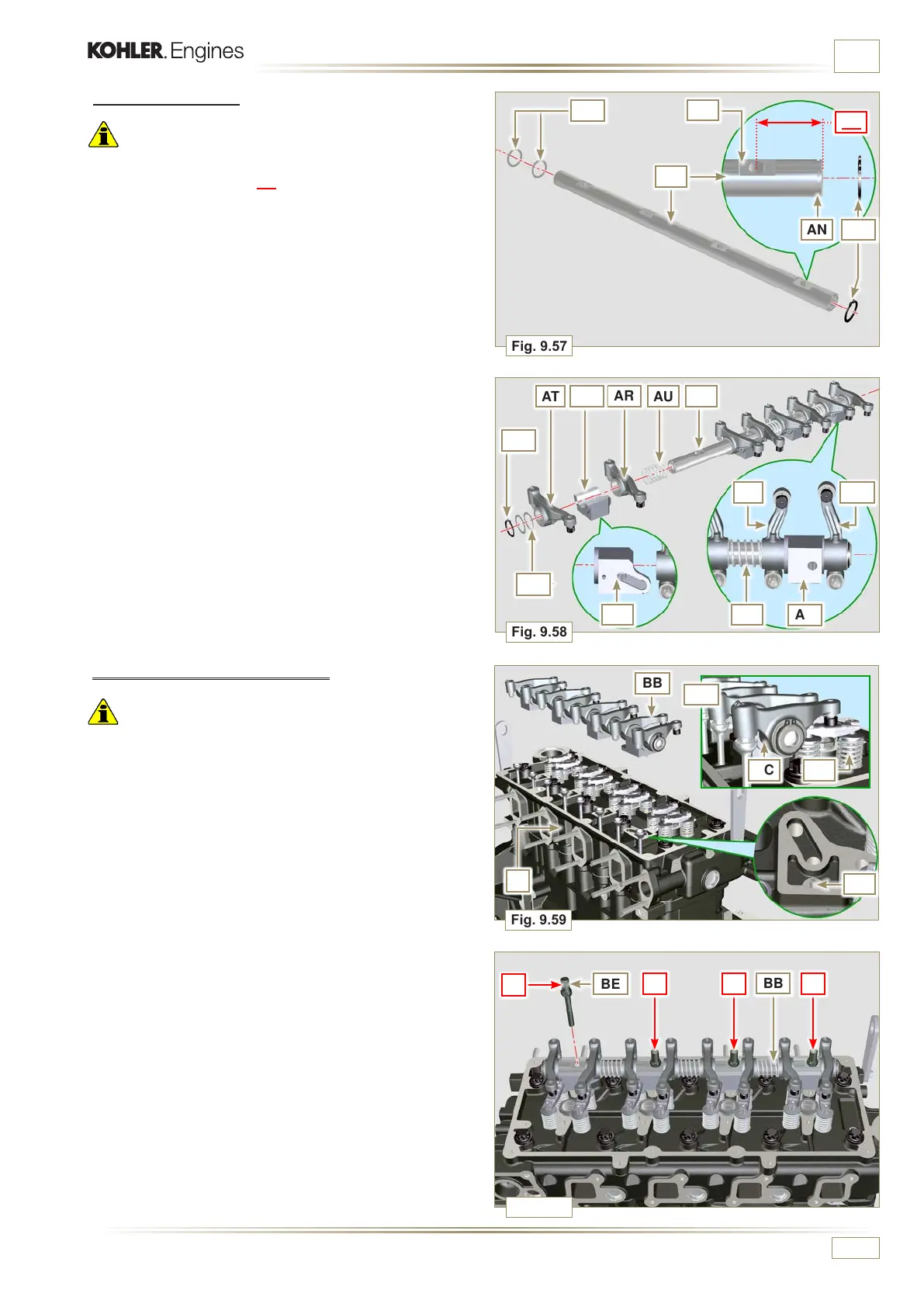

Fig. 9.59

BB

F

BC

BD

BB

BE

Fig. 9.60

12 3

4

AC AA

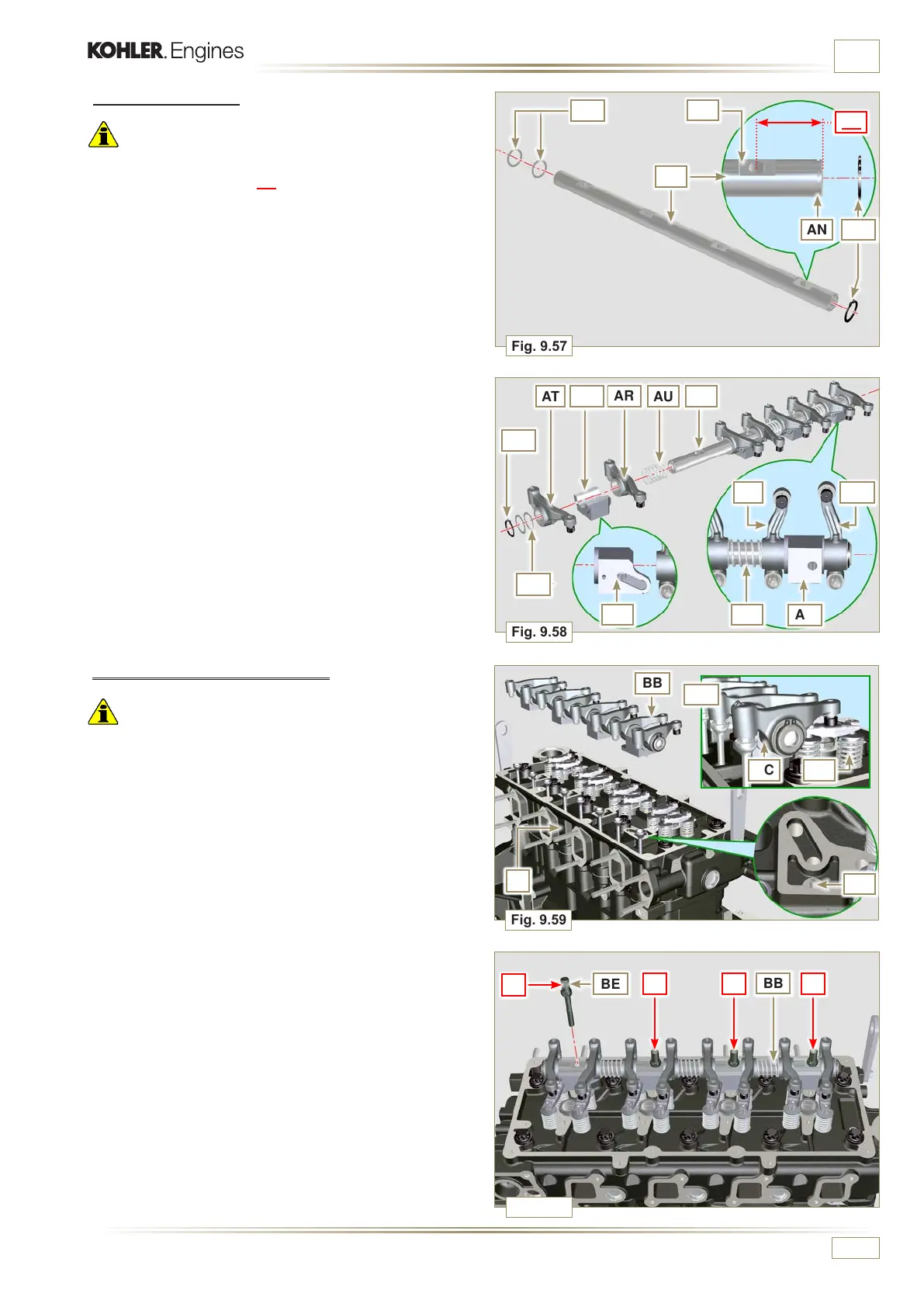

Fig. 9.57

AN

AP

AQ

AL

AH

Fig. 9.58

AR

AT

AU

AS

AUAV

AH

AR

AT

AS

AQ

AM

AM

ED0053029590

ASSEMBLY INFORMATION

9.7.8 Rocker arm pin assembly

Important

• Position the rocker arm pin assembly BB on a level to align

all the support surfaces.

• Check that the pistons are positioned half way between the

TDC and BDC. Rotate the crankshaft 90° counterclockwise

with regard to the 1

st

cylinder TDC, positioning the crankshaft

pin BP as shown in Fig 9.60a. If the crankshaft pulley and

the timing gear cover have not been removed, rotate the

crankshaft positioning the reference BQ located on the target

wheel in correspondence of the speed sensor, as shown in

Fig. 9.60b.

1 -

Position the rocker arm pin assembly BB on the head

F, respecting the plug BC on the head using the holder

indicated AV.

2 -

Check the correct positioning of all the rocker arms and the

u-bolt control valves (detail BD).

House the tappet in the seat of the rocker arms control rod.

3 - Secure the rocker arm pin BB tightening the screws

BE (tightening torque to 25 Nm). Adhere to the screw

tightening sequence BE as shown in Fig. 9.60.

9.7.7 Rocker arms

Important

• To correctly position the rocker arms, turn the rocker arm pin

AH with the lower height AL towards the timing system side

as in Fig.9.57.

• The discharge rocker arm AT is shorter than the suction arm

AR.

1 -

Fit the lock ring AM into the seat AN of the rocker arm pin

AH.

2 -

Position the pin AH with the screw support surface AP

facing upwards and insert the 2 shoulder rings AQ.

3 -

Insert in sequence the suction rocker arm AR, the holder

AS and the discharge rocker arm AT in the pin AH.

4 -

Insert the spring AU in the pin AH.

5 -

Repeat points 3, 4 for all the rocker arms.

NOTE:

The holder AV must be tted with the last pair of rocker

arms towards the ywheel.

6 - Insert 2 shoulder rings AQ and the lock ring AN to lock all

the components inserted in the pin AH.

NOTE:

The spring AU ensures that the supports AS and AV

are kept in place .

Loading...

Loading...