9

152

_07

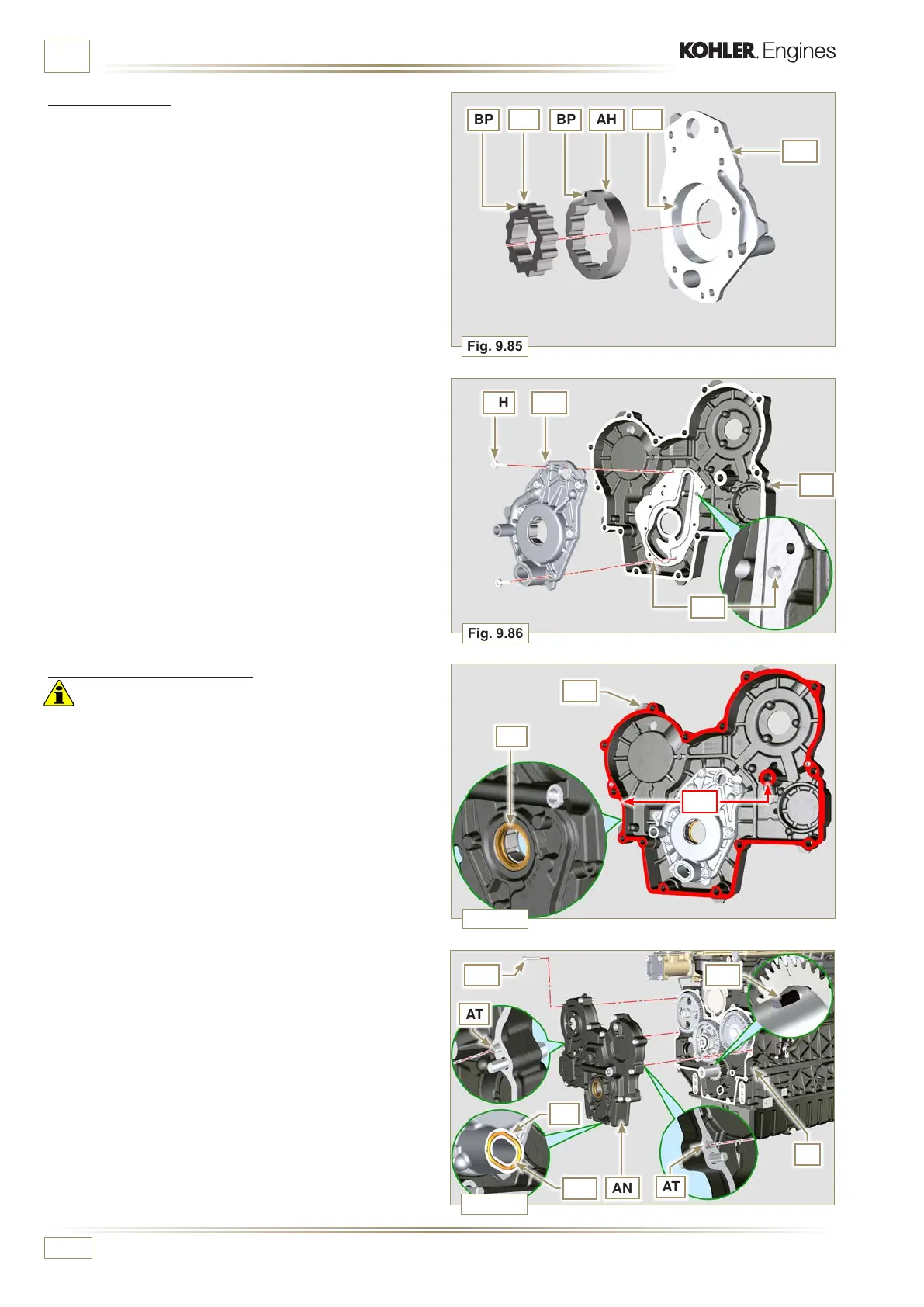

Fig. 9.85

AH AG

AM

AN

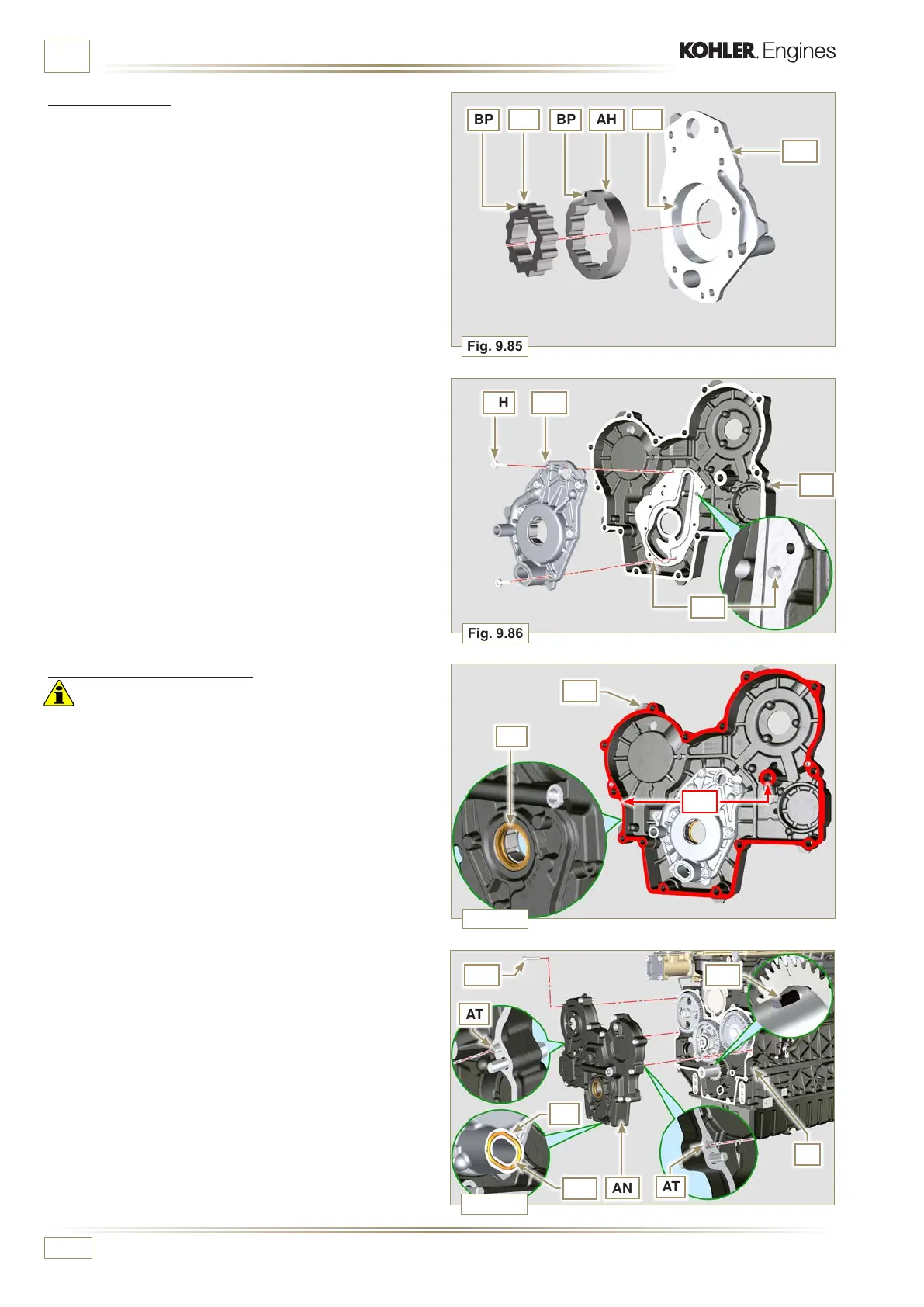

Fig. 9.86

AT

AT

E

AW

AN

AU

AV

AS

Fig. 9.88

Fig. 9.87

AQ

AN

AP

AHBPBP

AL

AG

AF

ED0053029590

ASSEMBLY INFORMATION

9.11.3 Oil pump

NOTE: Carry out the checks described in Par. 8.7 before

proceeding with the following operations.

1 - Check that all contact surfaces between AL, AH, AF, AG

and AN are free of impurities – scratches - dents.

2 - When assembling, do not use any type of gasket between

AG and AN.

3 - Thoroughly lubricate the seat of the rotors AF on the oil

pump crankcase AG and the two rotors AH and AL.

4 - Insert, inside the seat AF, the 2 rotors (in sequence) AH

and AL, respecting the reference BP as the picture (or

refer to Par. 2.10.2).

5 - Check that the 2 pins AM are inserted properly in the

crankcase timing system AN.

6 - Position the oil pump assembly AG using the pin marks

AM.

7 - Fasten the oil pump cover AG with the screws AH

(tightening torque 10 Nm).

9.11.4 Timing system carter

Important

• Always replace the gasket AU after each assembly.

• Always replace the gasket AP after each assembly (ST_14).

1 - Distribute a bead of Loctite 5188, of about 1mm thickness,

on the surfaces AQ of the crankcase AN.

2 - Make sure that the key AS (Fig. 9.88) is inserted properly

on the crankshaft and that it is facing upwards.

3 - Lubricate and insert the gasket AU in the seat of oil pump

AV.

4 - Apply the tool ST_10 onto the crankshaf.

5 - Check that the 2 pins AT (Fig. 9.88) are properly inserted

in the timing system crankcase AN.

6 -

Lubricate the gasket AP with oil and position the carter

AN on the crankcase E, using the pins AT, inserting the oil

pump AV on the crankshaft.

Loading...

Loading...