9

153

_07

AN

BE

BF

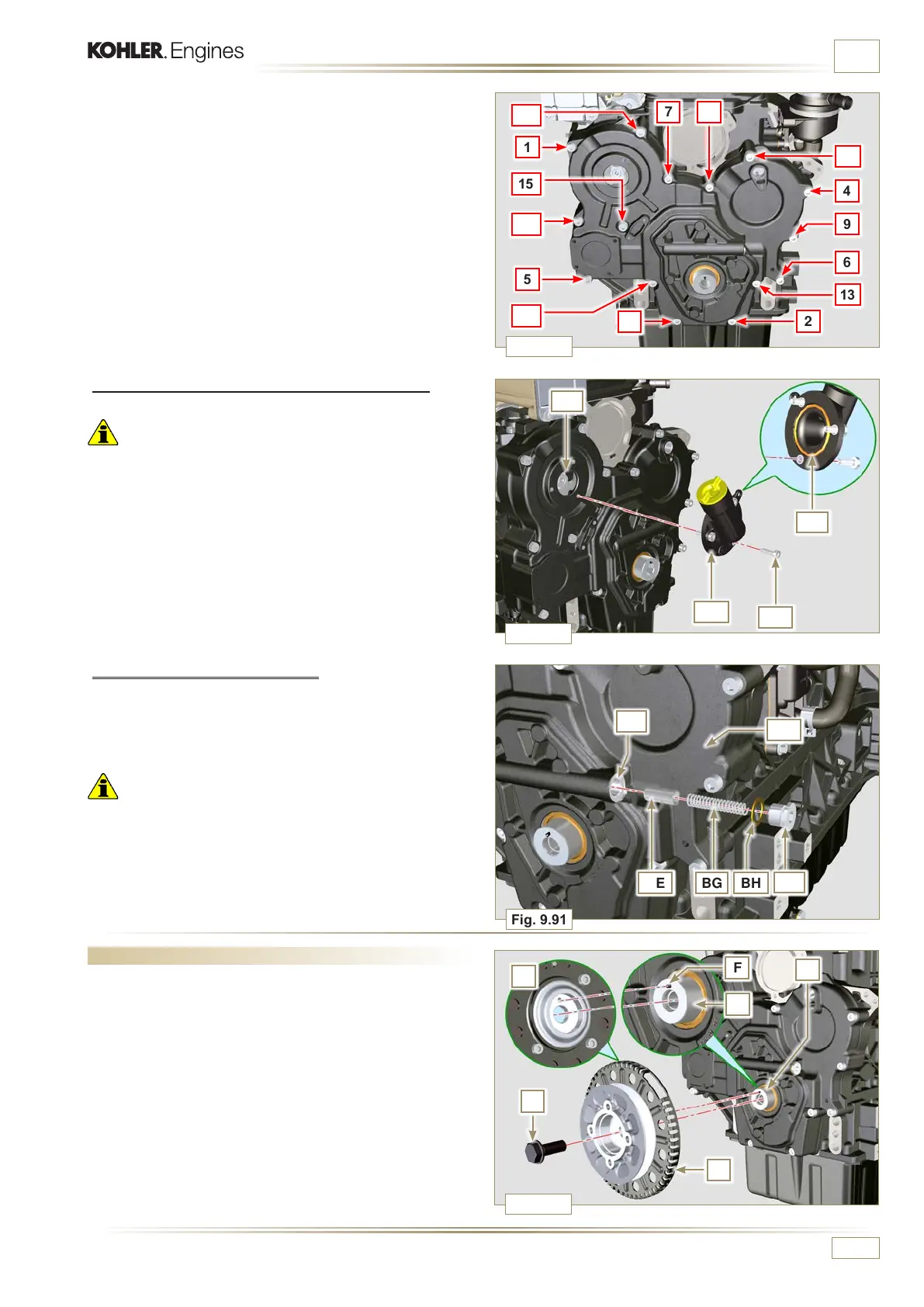

BG

BH

BL

Fig. 9.91

Fig. 9.90

BC

1

15

10

5

14

3

12

7 8

2

13

6

9

4

11

Fig. 9.89

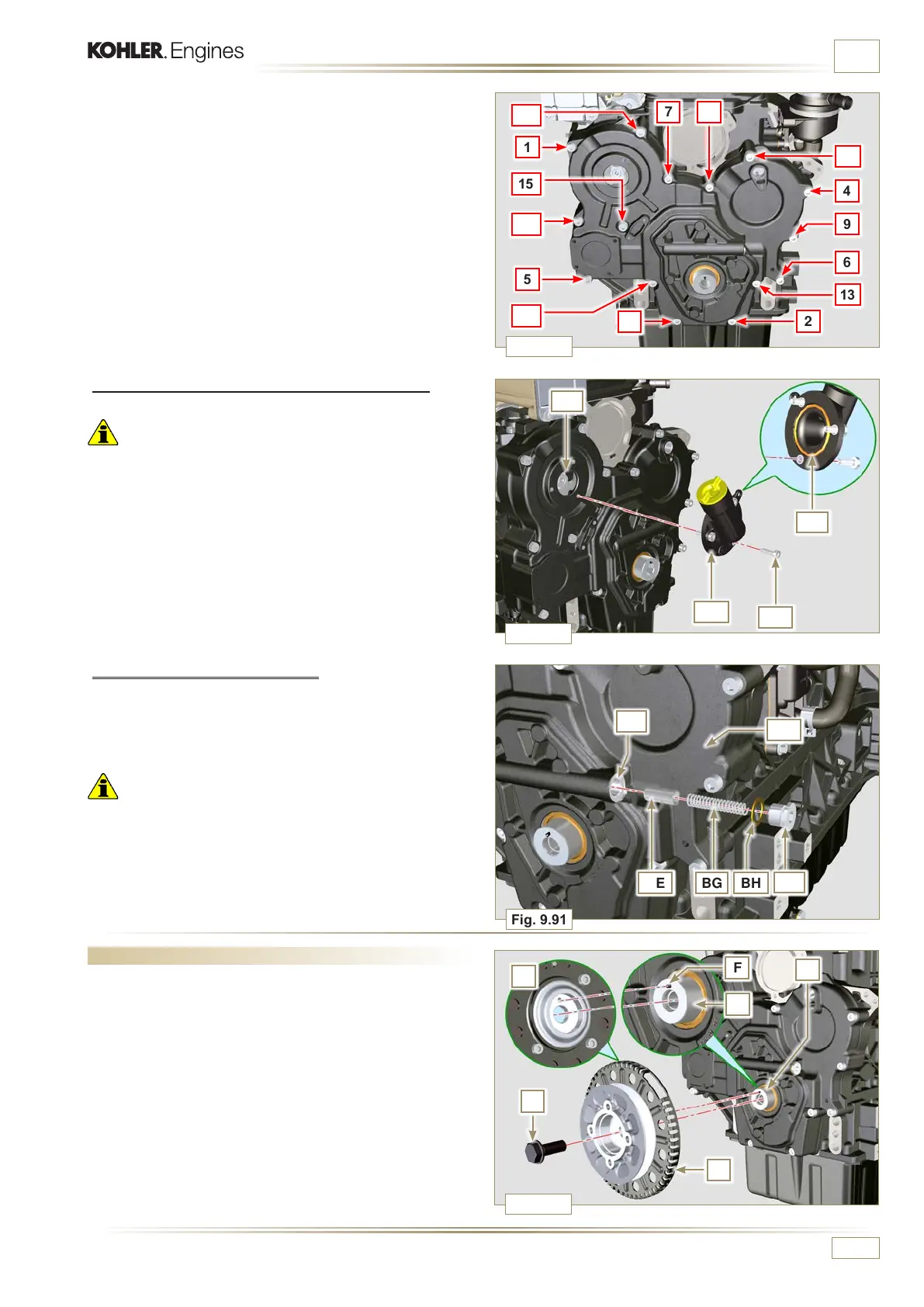

F

G

H

G

N

M

Fig. 9.92

BB

BD

BA

ED0053029590

ASSEMBLY INFORMATION

9.11.6 Oil pressure relief valve

1 - Lubricate the piston BE and fully insert it in the seat BF.

2 - Insert the spring BG in the piston.

Important

• Always replace the gasket BH after each assembly.

3 - Mount the gasket BH on cap BL.

4 - Tighten the cap BL on the crankcase AN (tightening torque of

50 Nm).

9.11.5 Crankcase oil ller ange Timing System

Important

• Always replace the gasket BA after each assembly.

1 - Position the gasket BA in the seat on the flange BB.

2 - Fasten the flange BB on the crankcase BC with the screws

BD (tightening torque of 8 Nm - ST_06).

7 -

Fasten capscrews AW observing the indicated clamping

sequence (tightening torque of 25 Nm).

9.12 Crankshaft and phonic wheel pulley unit assembly

NOTE:

To t the phonic wheel refer to the operations in

Par. 6.6.2.

1 -

Check that the pin F is mounted properly on the crankshaft

G.

2 -

Position the pulley unit H on the crankshaft G using the pin

mark F (detail M).

3 -

Apply Molyslip grease on the screw thread N.

4 -

Fix the pulley T with the screw Z (tightening torque of 360

Nm) and remove special tool ST_34 (Fig. 9.33).

Loading...

Loading...