9

157

_07

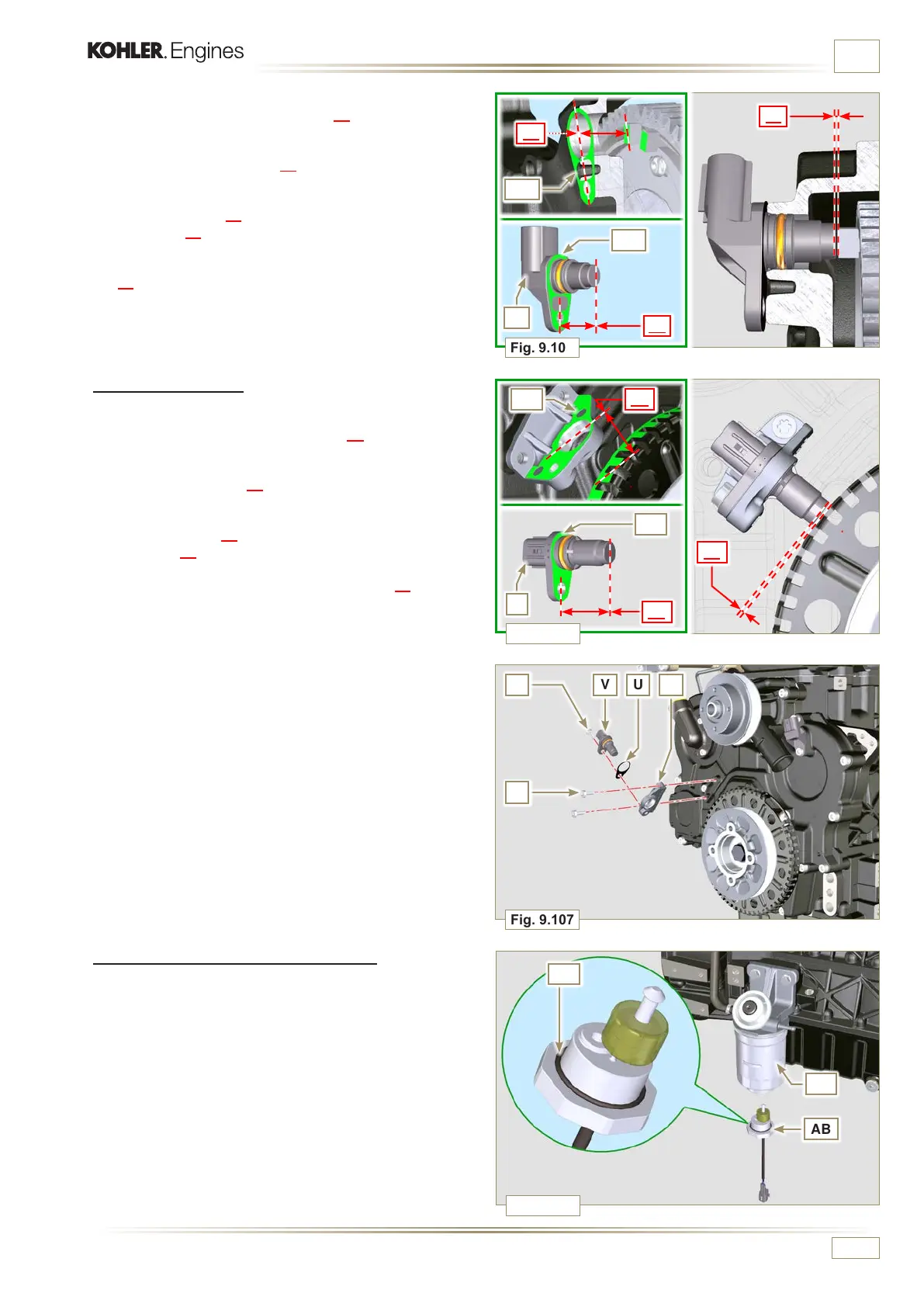

Fig. 9.107

Z

T

V U S

AB

AC

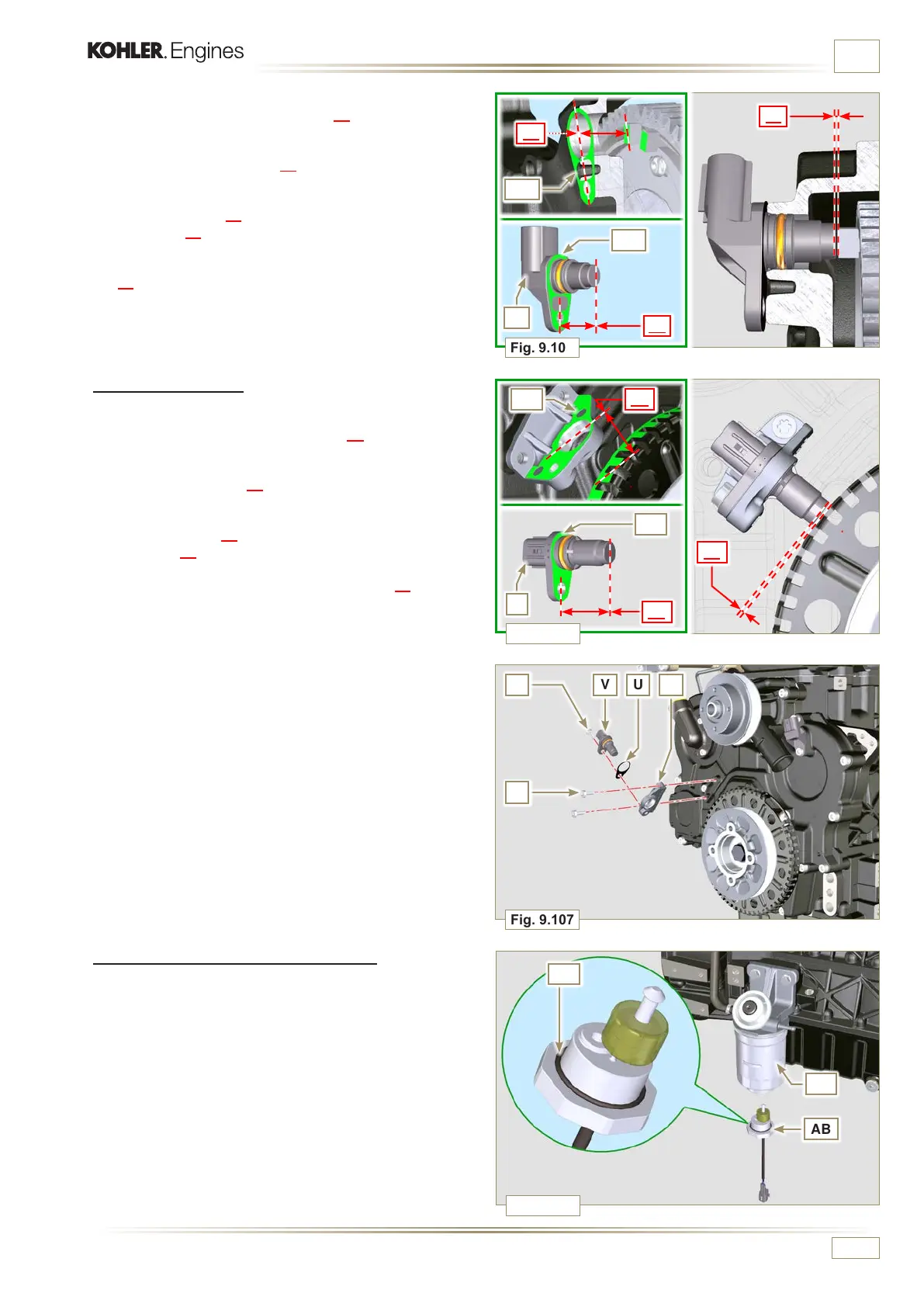

Fig. 9.108

AA

Fig. 9.105

X1

X2

Z1

Y1

Y2

Z2

AD

AE

AD

AE

R

V

Fig. 9.106

ED0053029590

ASSEMBLY INFORMATION

9.15.1.5 Speed sensor

1 - Measure the distance from the coupling surface AE to the

external diameter of the phonic wheel (X2).

2 - Measure the distance between the coupling surface AE and

the sensor surface V (Y2).

3 - The difference between the 2 measurements

determines

the air gap value (Z2).

The value (Z2) permitted must be a minimum of 0.2 mm and

a maximum of 1.2 mm.

Insert one or two spacers U based on the value (Z2) detected.

NOTE: The calibrated spacers U have a thickness of 0.2mm.

4 - Mount the bracket S with the screws T (tightening torque at

10 Nm - ST_06).

5 - Insert the shim U on the sensor V.

6 - Clamp the sensor V on the bracket S with the screw Z

(tightening torque at 10 Nm - ST_06).

5 - Measure the distance from the coupling surface AD to the

tooth surface on the phonic wheel (X1).

6

- Measure the distance between the coupling surface AD

and the sensor surface R (Y1).

7 - The difference between the 2 measurements determines

the air gap value (Z1).

The value (Z1) permitted must be a minimum of 0.2 mm

and a maximum of 1.2 mm.

Insert one or two spacers N (Fig. 9.104) based on the value

(Z1) detected.

NOTE:

The calibrated spacers N have a thickness of 0.2mm.

9.15.1.6 Fuel lter water detection sensor

1 - Lubricate and insert the gasket AA on the fitting AB.

2 - Tighten the sensor AB onto the cartridge AC (tightening

torque of 5 Nm).

Loading...

Loading...