9

158

_07

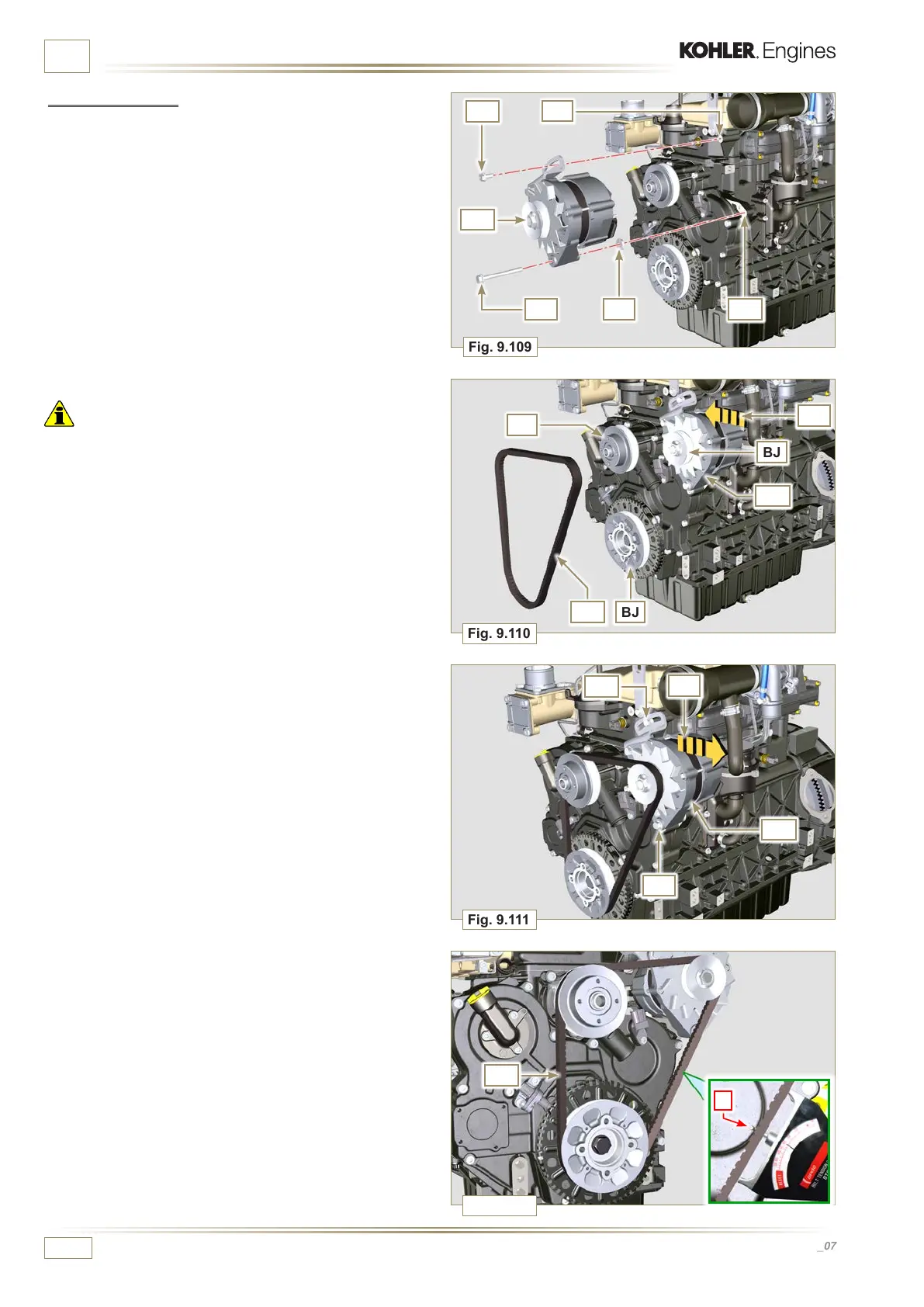

BE

BA BC

BD

BF

Fig. 9.109

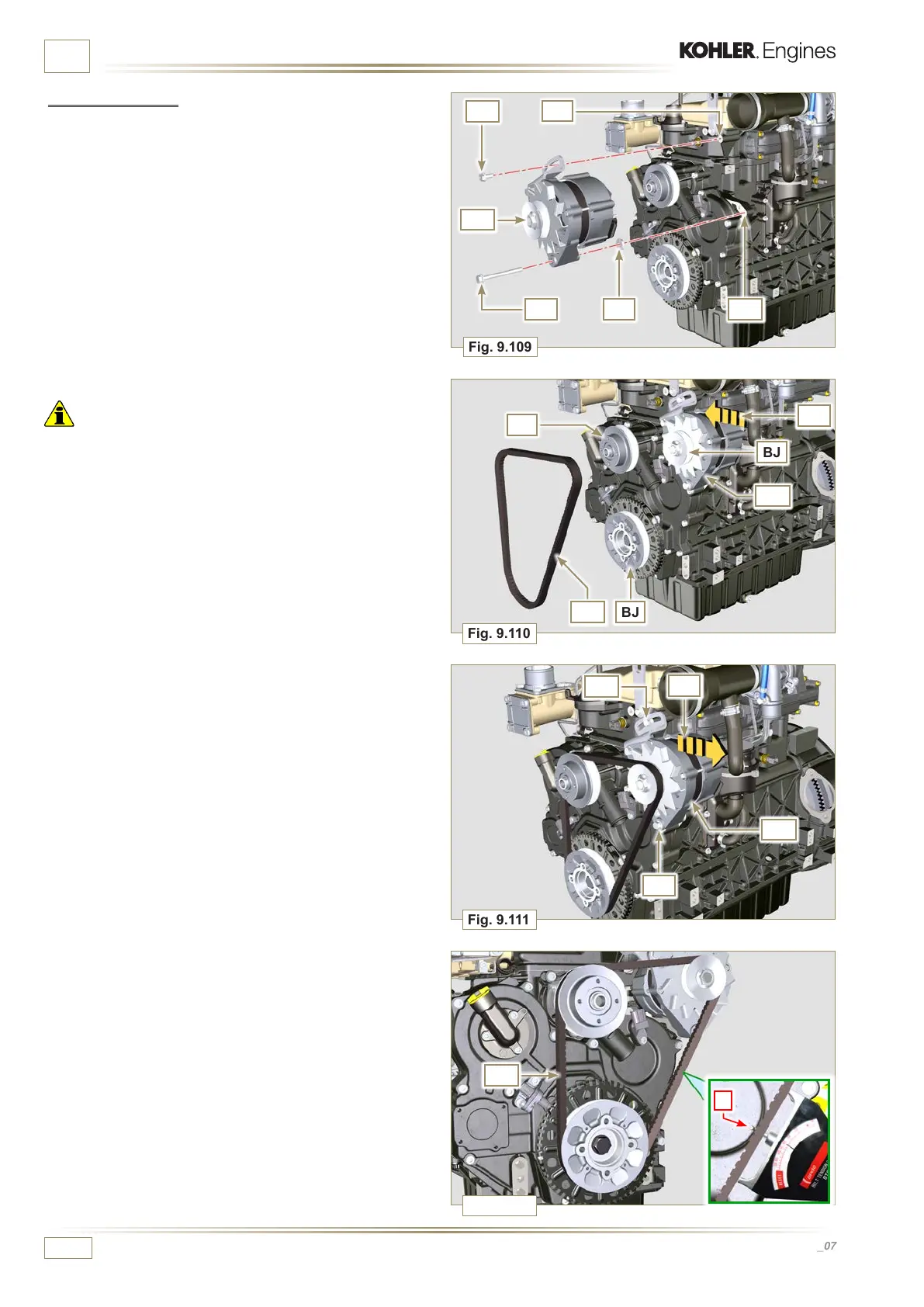

BJ

BH

BJ

BJ

BG

BB

Fig. 9.110

BK

Fig. 9.111

BE

BB

BA

BH

Fig. 9.112

BB

P

ED0053029590

ASSEMBLY INFORMATION

5 - Pull out the dipstick BB in the direction of the arrow BG.

Important

• The belt BH must always be replaced every time it is

assembled, even if it has not reached the scheduled hours

for replacement.

6 - Insert the belt BH on the pulleys BJ.

9.15.2 Alternator

1 - Insert the screw BA onto the alternator BB.

2 - Insert the washer BC onto the screw BA.

3 - Manually fit the screw BA all of the way onto the crankcase

BD without tightening.

4 - Manually fit the screw BE all of the way onto the head BF

without tightening.

7 -

Pull out the dipstick BB in the direction of the arrow BK.

8 - While tensioning the alternator BB, first clamp screw BE

(tightening torque at 25 Nm) and then screw BA (tightening

torque at 69 Nm).

9

- Check the tension of the belt BH with a Clavis type

instrument, positioning it in point P (the tension must be

between 350 and 450 N).

10 - If the tension values do not correspond, tighten screws BA

and BE, then repeat operations 7, 8 and 9.

Loading...

Loading...