185

11

_07

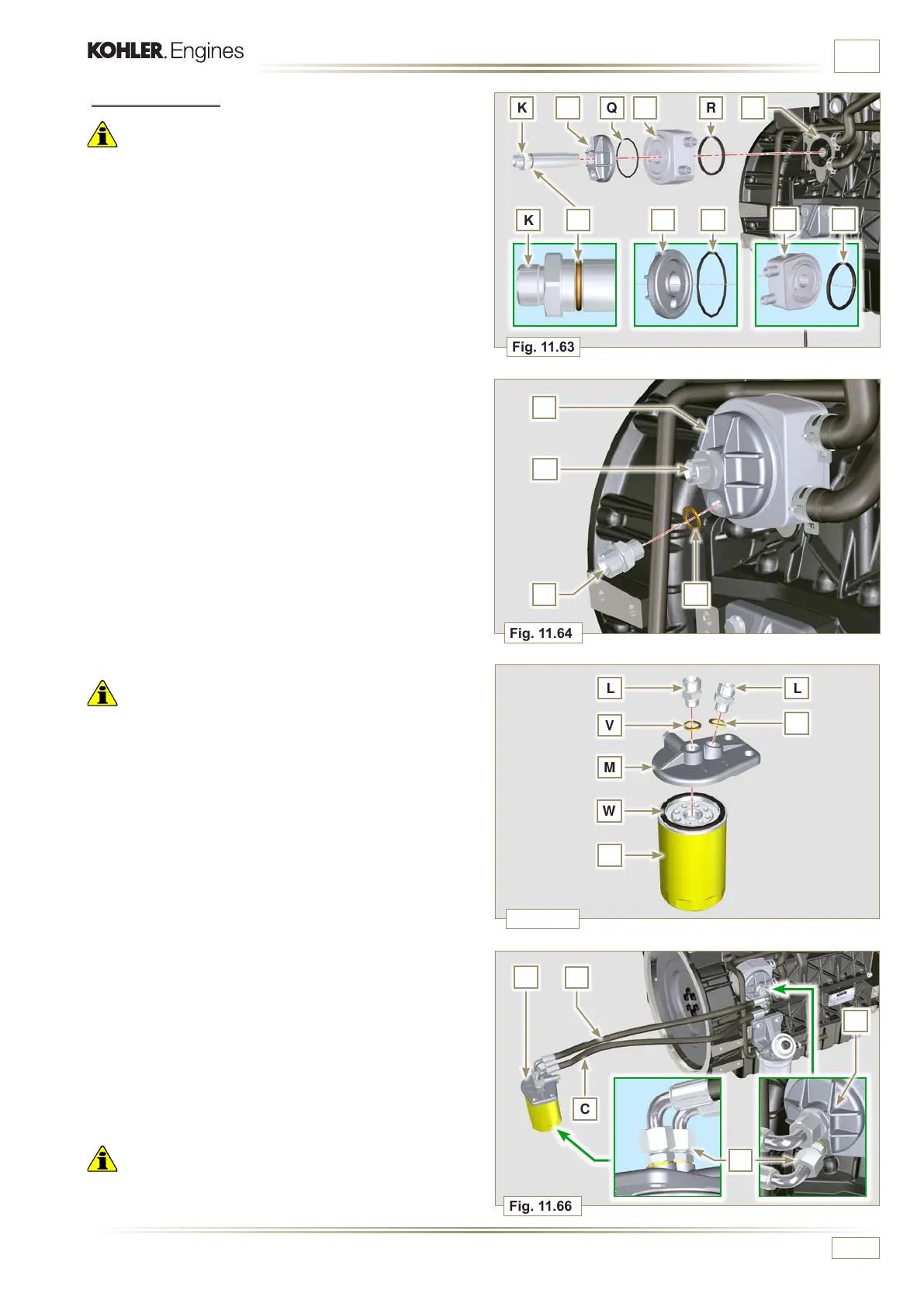

Fig. 11.65

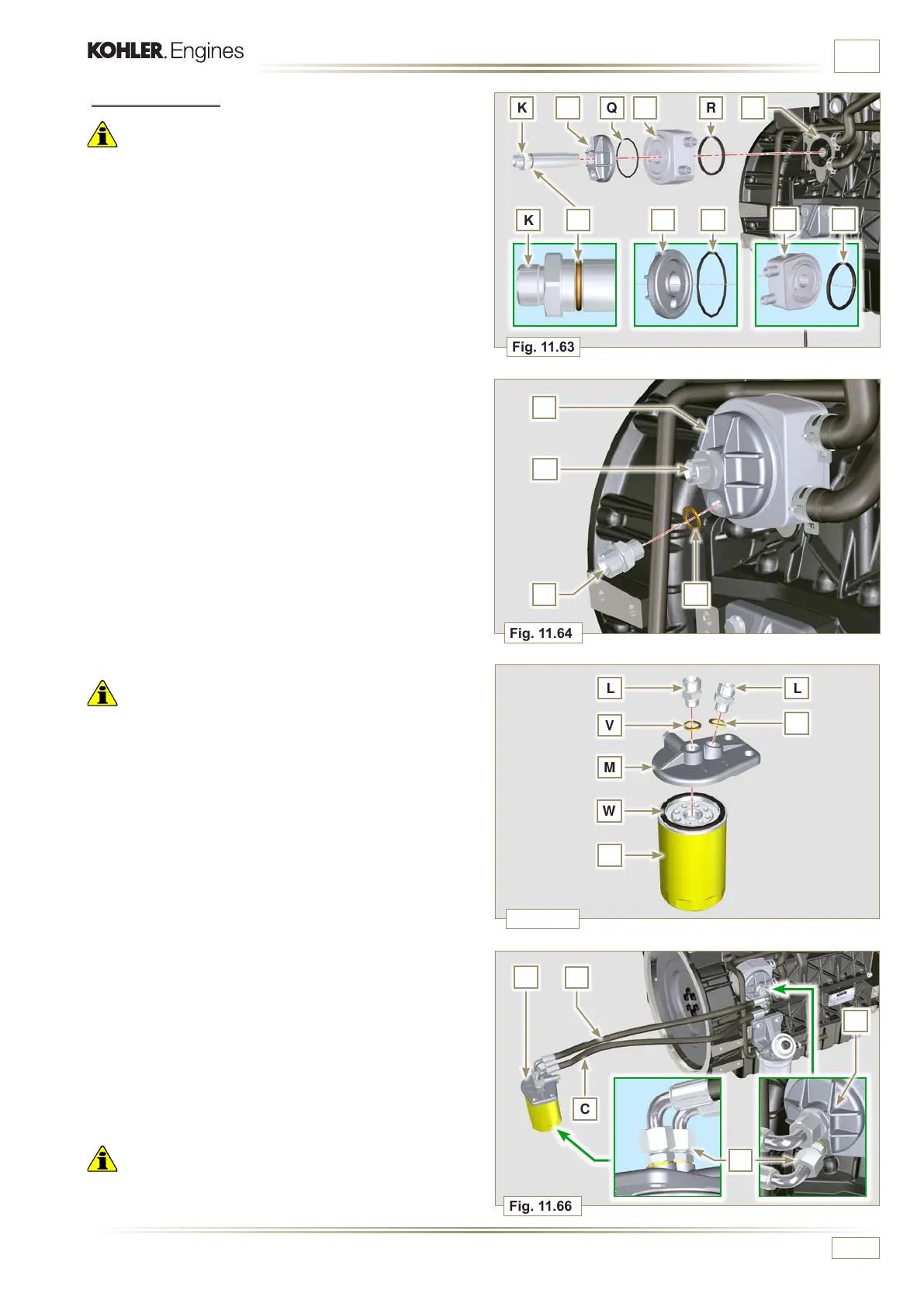

Fig. 11.66

L

V

M

W

N

L

V

M

B

C

A

Fig. 11.64

J

H U

Fig. 11.63

K Q G R SJ

J Q

R

K

G

P

K

J

ED0053029590

INFORMATION ABOUT OPTIONAL COMPONENTS

Important

• Always replace the gaskets V after each assembly.

6 - Clamp unions L on support M inserting gasket V (tightening

torque at 40 Nm).

7 - Lubricate gasket W and clamp cartridge N on support M

(tightening torque at 20 Nm).

8 -

Connect tube B to the central union of support M and of

head J.

9 - Connect tube C to the side union of support M and of head

J.

10 - Clamp the nuts A on the head J (tightening torque at 30

Nm).

11 - Clamp the nuts A on support M (tightening torque at 35

Nm).

Important

• Check the tightening of the fittings K, H (Fig. 11.64) and L

(Fig. 11.65) (tightening torque at 40 Nm).

11.11.2 Assembly

Important

• Always replace the gaskets P, Q, R and U at each assembly.

• Lubricate the gaskets P, Q and R with oil before assembling

them.

1 -

Insert the gasket P on the seat of the fitting K.

2 -

Insert flange head J on the union K and the gasket Q in the

seat of head J.

3 -

Insert the Oil Cooler G on the union K and the gasket R in

the seat of Oil Cooler G.

4 -

Onto crankcase S apply Oil Cooler G and flange J by

means of union K (tightening torque at 25 Nm + Loctite

2701 on thread) as positioned in Fig. 11.64.

5 - Clamp union H on flange J inserting gasket U (tightening

torque at 40 Nm).

Loading...

Loading...