186

11

_07

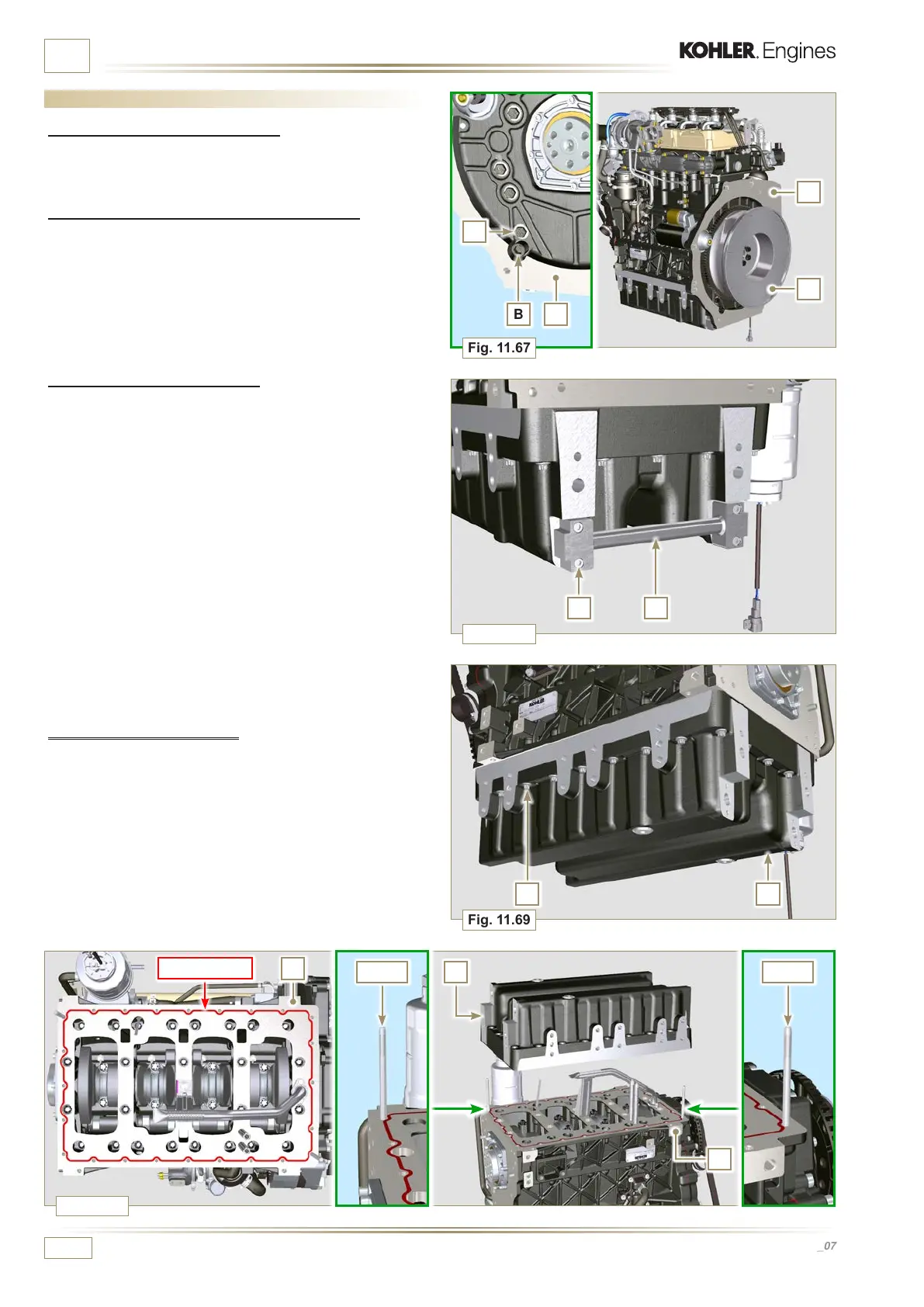

Fig. 11.67

Fig. 11.68

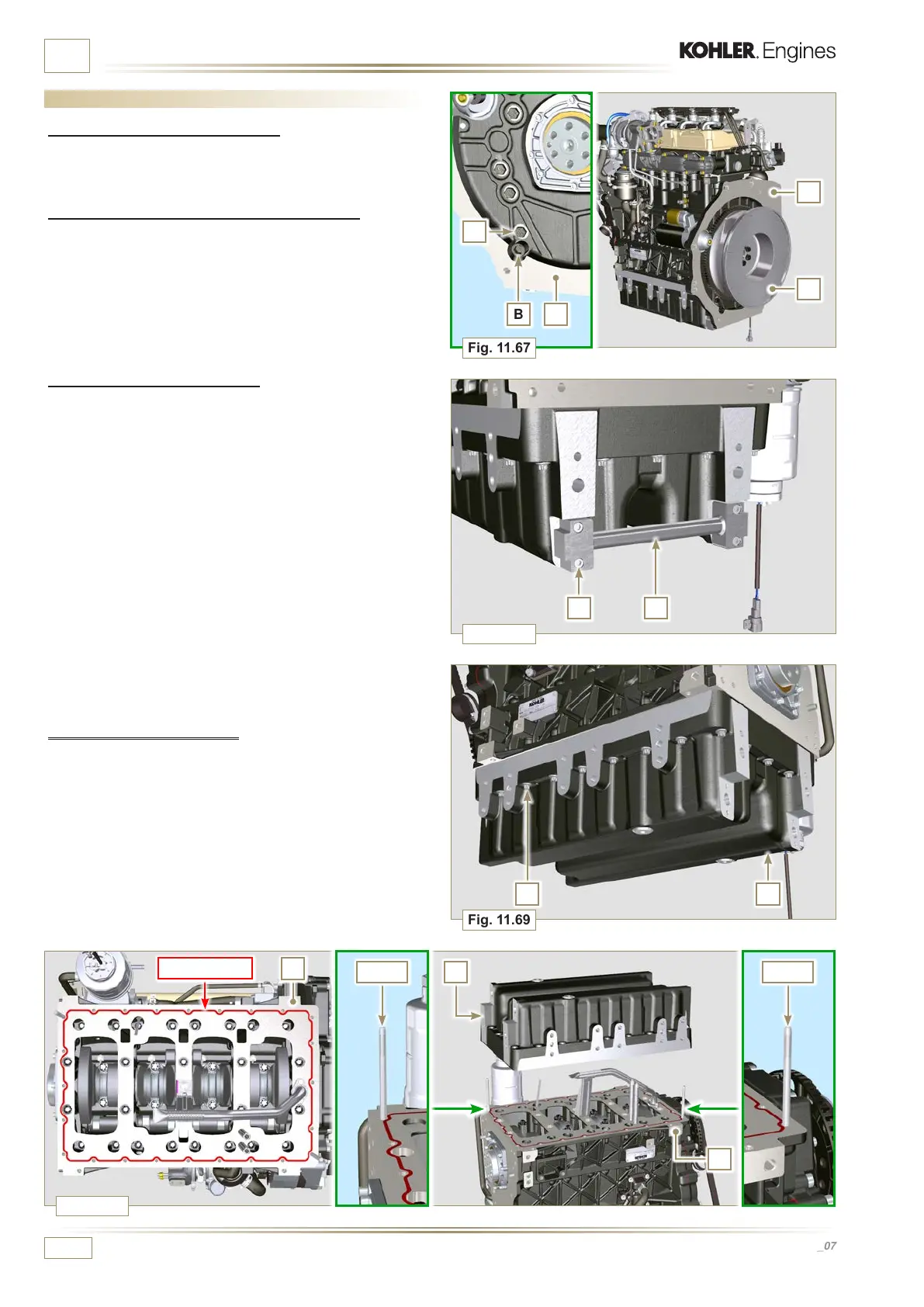

Fig. 11.69

Fig. 11.70

A

B

C

E

ST_18 ST_18

F

H

G

Loctite 5660

F

D

L

J

L

ED0053029590

INFORMATION ABOUT OPTIONAL COMPONENTS

11.12 Oil sump with supporting structure

11.12.1 Flywheel (J) disassembly

1 - Execute the operations described in Par. 7.12.1.

11.12.2 Plate/ange housing (L) disassembly

1 - Loosen supplementary capscrews A and B.

2 -

Execute the operations described in Par. 7.12.2.

3 - Remove housing or plate L.

11.12.3 Oil sump disassembly

1 - Execute the operations described in Par. 5.2.

2 -

Loosen capscrews C and remove bypass tube D.

3 -

Loosen capscrews E and remove oil sump F.

11.12.4 Oil sump assembly

1 - Make sure contact surfaces G of oil sump F and crankcase H

have no impurities.

2 - Apply a sealing bead of approximately 2.5 mm (Loctite 5660)

onto surface G of crankcase H.

3 - Place oil sump F onto crankcase H in correspondence with the

fastening holes (use tool ST_18).

Loading...

Loading...