187

11

_07

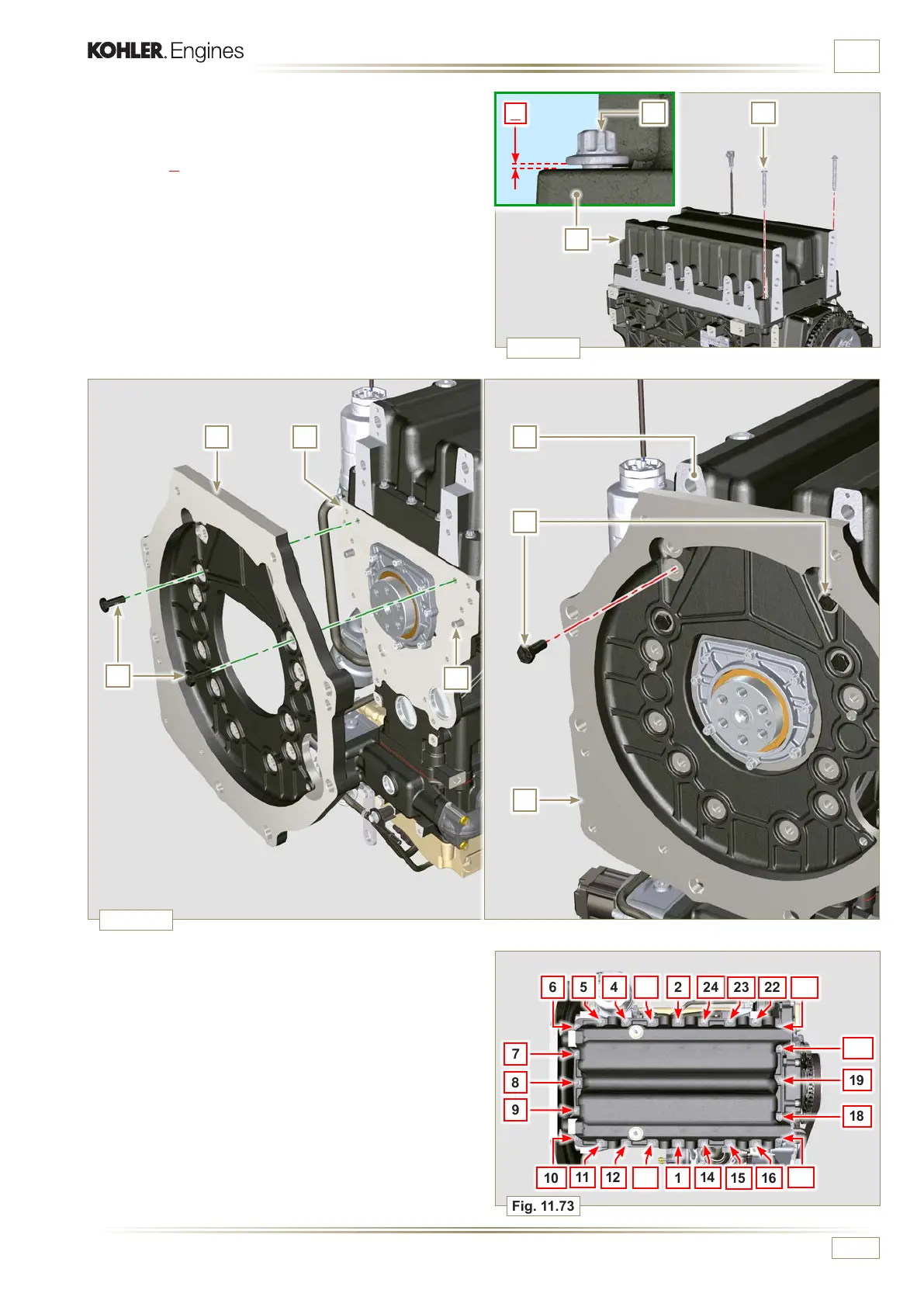

Fig. 11.71

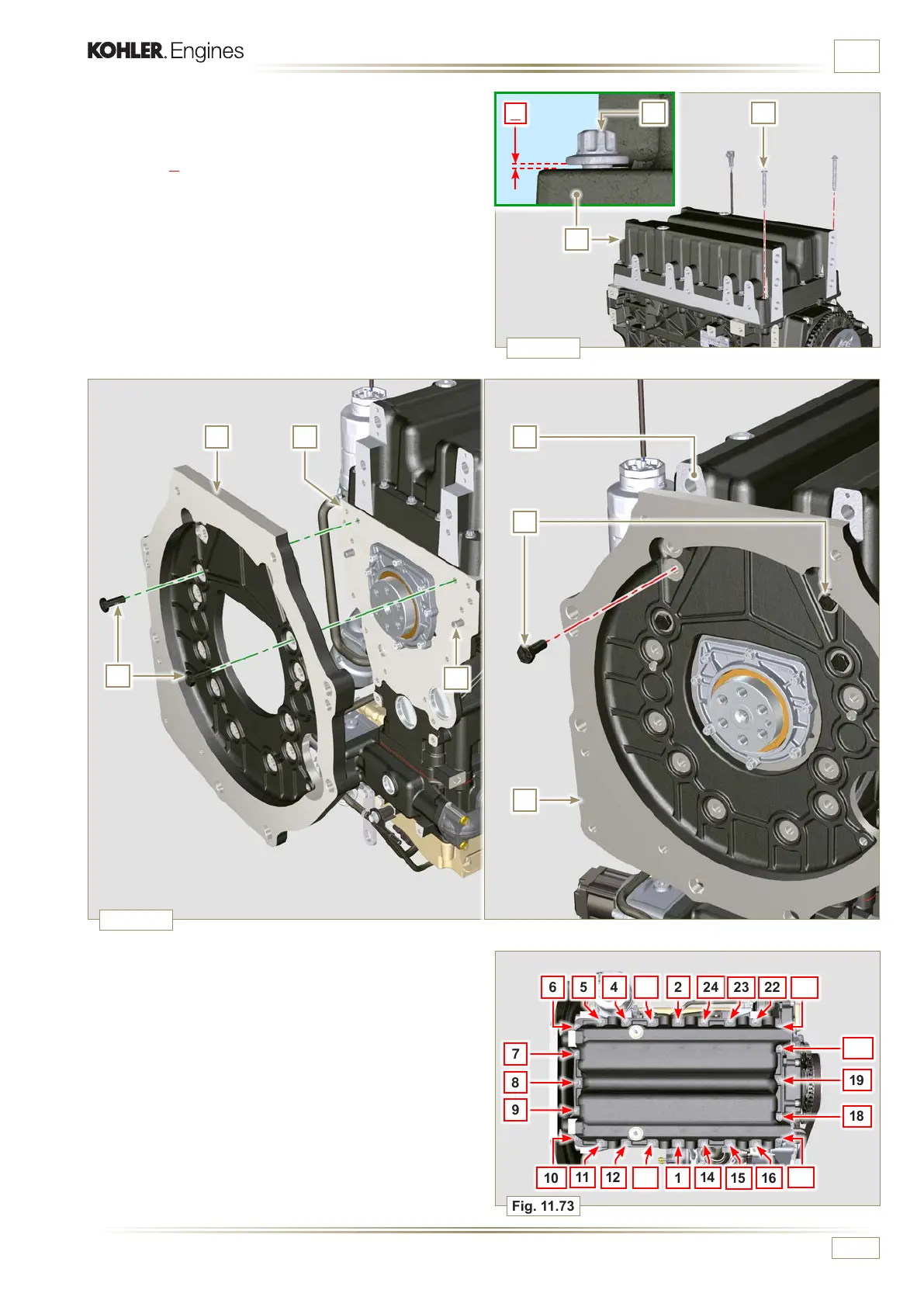

Fig. 11.73

Fig. 11.72

A

E

F

E

L

L

F

A

A

H

M

1

14

15

16

17

18

19

20

2

24

23

22

21

10

11

12

13

9

8

7

6 5 4 3

ED0053029590

INFORMATION ABOUT OPTIONAL COMPONENTS

4 - Apply capscrews E into the fastening holes and use torque

at 10 Nm.

5 -

Loosen capscrews E, leaving approximately 1 mm leeway

(position A) between the neck surface of capscrews E and

oil sump F.

6 -

Place flange housing or plate L onto crankcase H,

complying with centring tap pins M.

7 - Using 2 capscrews A, fasten housing or plate L onto

crankcase H (tightening torque at 20 Nm).

8 -

Using 2 capscrews A, fasten housing or plate L onto oil

sump F (tightening torque at 20 Nm).

9 - Fasten oil sump F by tightening capscrews E and strictly

following the order shown in Fig. 11.73 (tightening torque

at 20 Nm).

10 - Loosen capscrews A and remove housing or plate L (Fig.

11.72).

11 -

F a sten oil sump F by tightening capscrews E and strictly

following the order shown in Fig. 11.73 (tightening torque

at 47 Nm).

Loading...

Loading...