6

81

_07

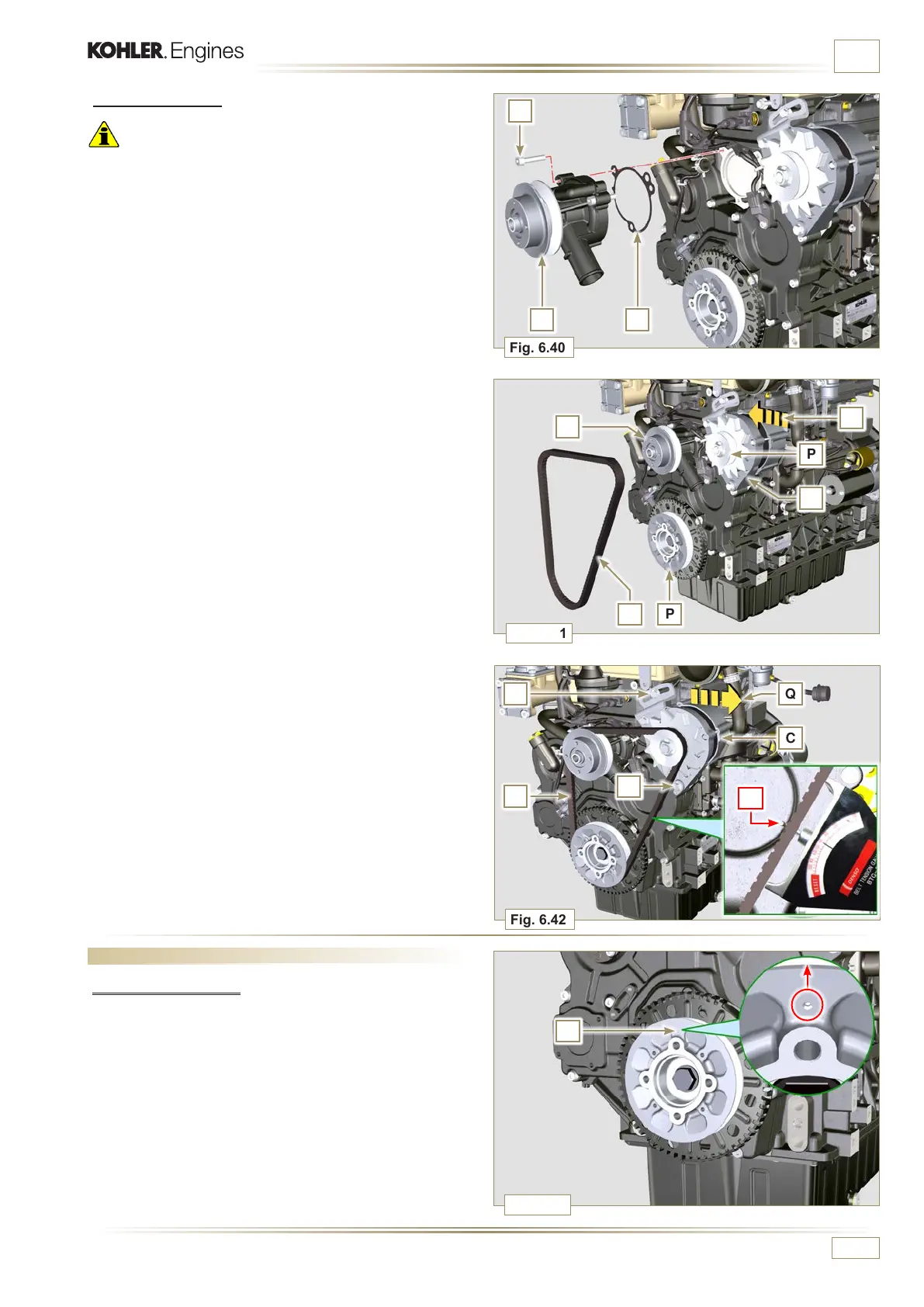

Fig. 6.40

N

H

L

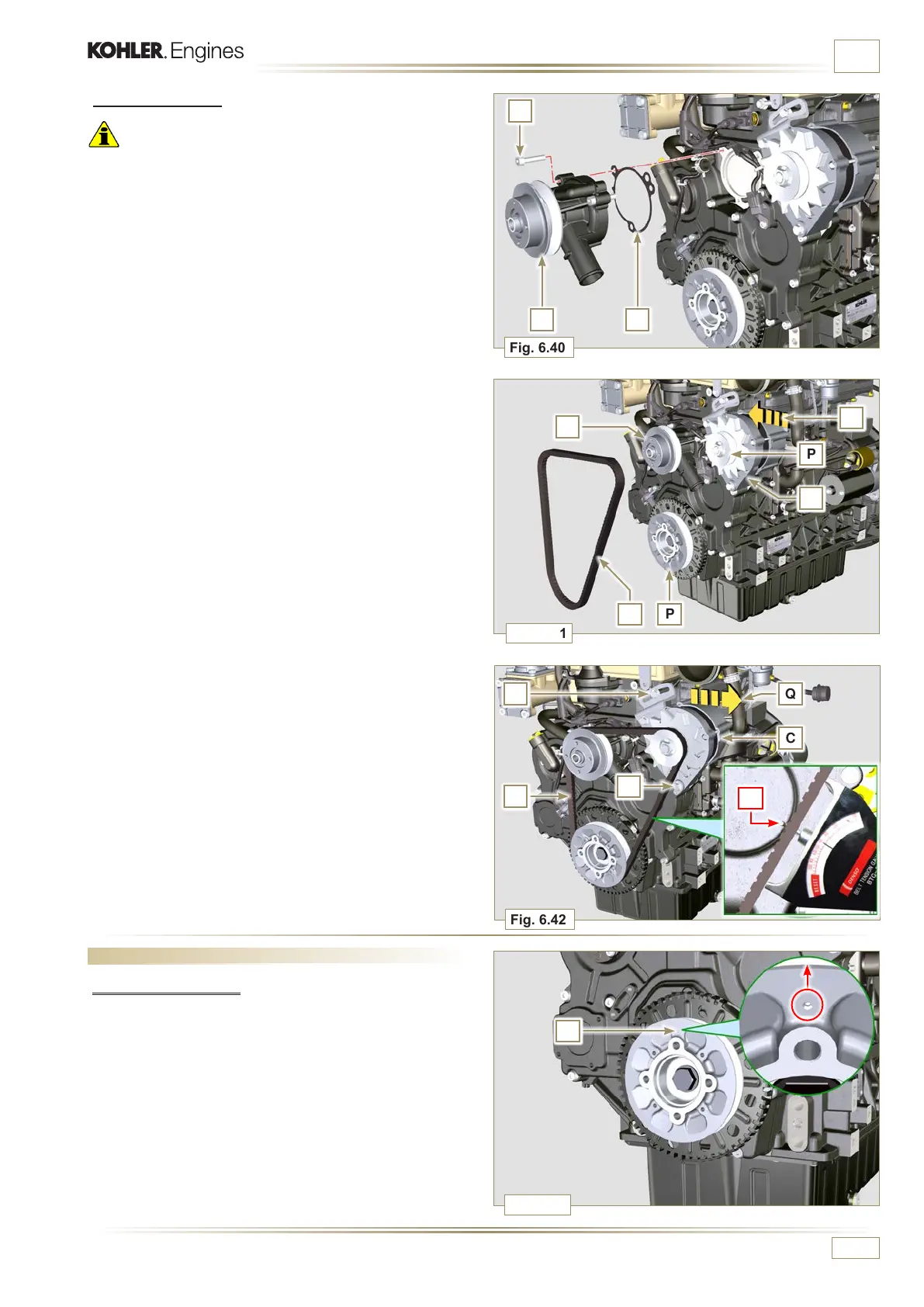

Fig. 6.42

E

A Q

C

B

Fig. 6.41

PE

P

P

D

C

Fig. 6.43

A

P

ED0053029590

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

6.5.2 Assembly

Important

• Always replace the gaskets L, at each disassembly.

• Always replace the belt E after each assembly.

• If the engine is fitted with the Poly-V belt, perform the

operations described in Par. 11.3.

1 - Fit the pump N with the screws H interposing the new

gasket L (tightening torque at 25 Nm).

2 -

Reinsert the pipe G and hook the clamp F (Fig. 6.38).

3 - Rehook the clamp M on the pump N (Fig. 6.39).

4 - Push the alternator C in the direction of the arrow D.

5 - Insert the belt E on the pulleys P.

6 -

Pull the alternator C in the direction of the arrow Q.

7 - While tensioning the alternator C, first clamp screw A

(tightening torque at 25 Nm) and then screw B (tightening

torque at 69 Nm).

8 - Check the tension of the belt E with the instrument

(DENSO BTG-2), positioning it in point P (the tension must

be between 350 and 450 N).

9 - If the tension values do not correspond, tighten screws A

and B, then repeat operations 6, 7 and 8.

6.6 Target wheel replacement

6.6.1 Disassembly

1 - Position the crankshaft with the 1st cylinder in TDC,

reference A upwards.

2 - Remove the alternator belt following steps 1 and 2

(Par. 6.5.1).

Loading...

Loading...