6

83

_07

C

D

E

Fig. 6.51

Fig. 6.50

B

C

A

H

S

Fig. 6.49

S

AE

Fig. 6.48

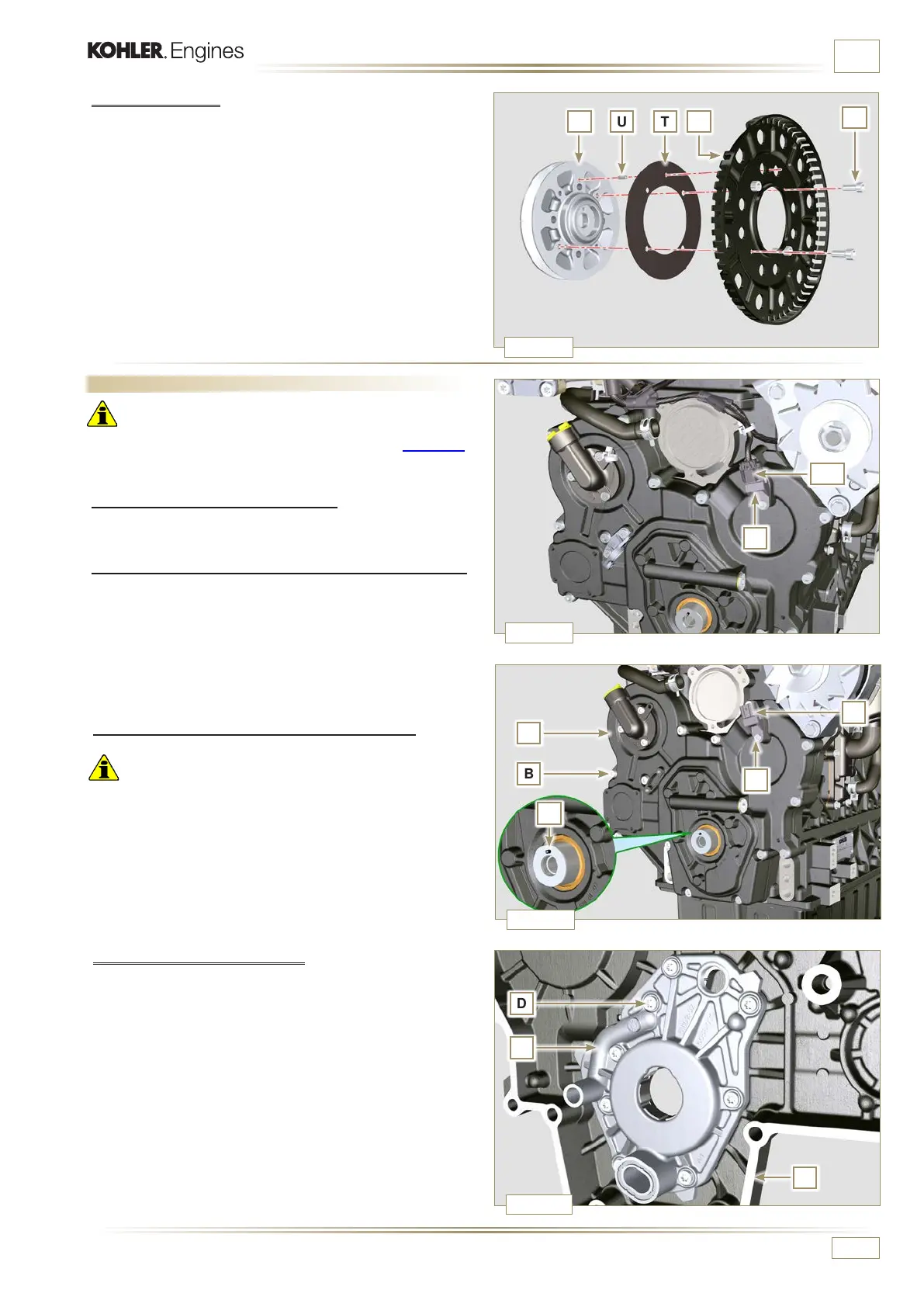

UV T S

W

ED0053029590

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

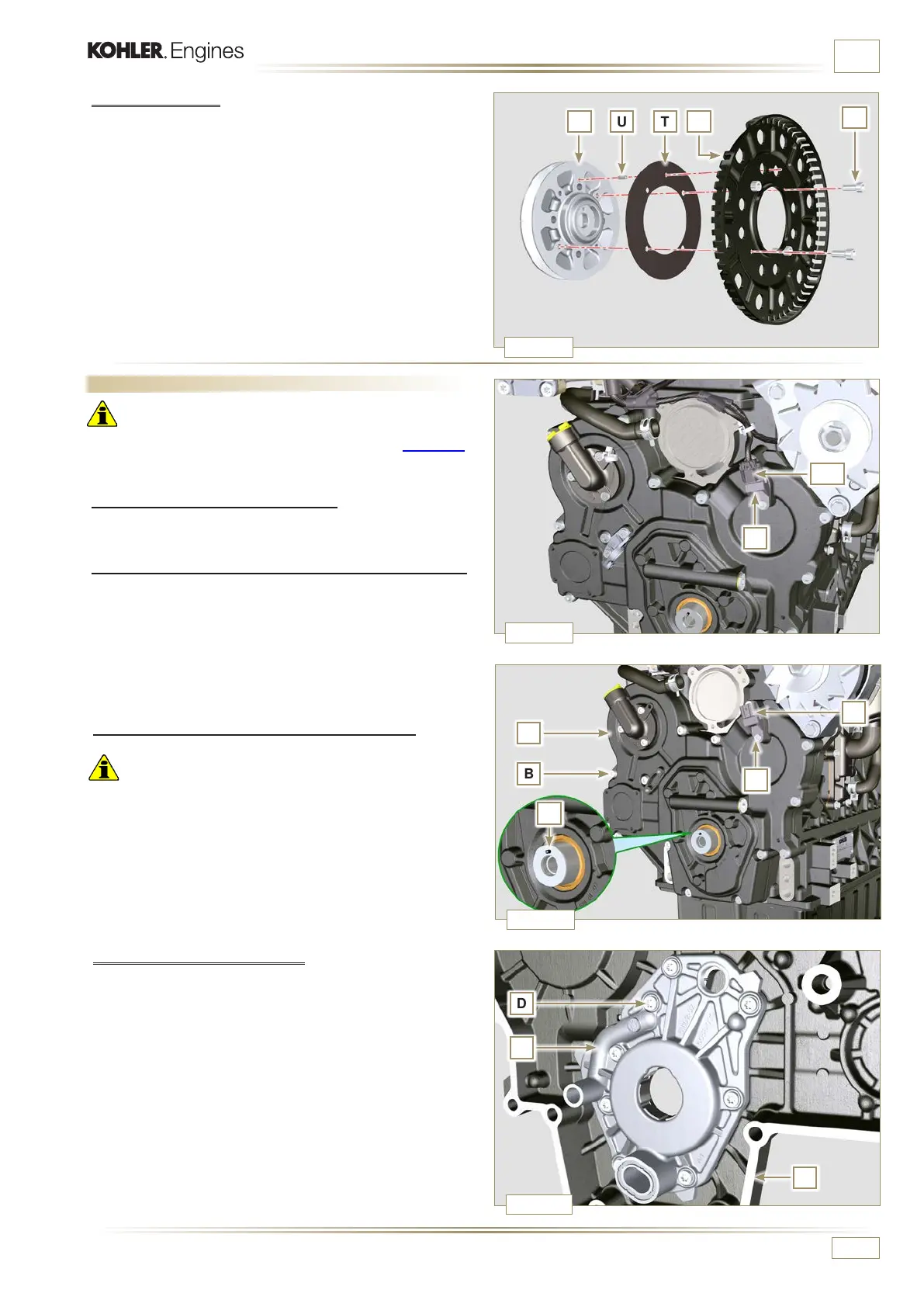

6.7.3 Timing system crankcase disassembly

Important

• Perform the operations described in Par. 5.2.

1 - Make sure that the reference pin A is facing upwards.

2 - Undo the screw H (ST_06) and remove the sensor S.

3 - Undo the screws B and remove the timing system

crankcase C.

6.7.4 Oil pump disassembly

1 - Undo the screws D (ST_06) and remove the group pump E

from the timing system crankcase C.

6.7 Oil pump replacement

Important

• Before proceeding with operation, carefully read Par. 3.3.2.

• The oil pump is not repairable.

6.7.1 Coolant pump disassembly

1 - Perform the operations described in Par 6.5.1.

6.7.2 Crankshaft and target wheel pulley disassembly

1 - Perform the operations described in Par 6.6.1 - points 1

to 7.

2 - Disconnect the connector AE from the sensor S.

6.6.2 Assembly

1 - Check that the pin U is mounted properly on the pulley V.

2 -

Insert the disk T on the pulley V respecting the reference of

the pin U.

3 -

Position the phonic wheel S on the pulley V respecting the

reference of the pin U.

4 -

Fit the phonic wheel S with the screws W (tightening torque

10 Nm).

5 - Perform the operations described in Par. 6.7.7 and then

the operations between point 2 and 9 of Par. 6.5.2.

Loading...

Loading...